Environment-friendly treatment method for recycling alloy electroplating liquid

An alloy electroplating solution and environmental protection treatment technology, applied in chemical instruments and methods, electrolytic processes, electrolytic components, etc., can solve problems such as inability to react with alloy electroplating solutions, poor removal effect of heavy metal ions, inconvenient removal of heavy metal compounds, etc., and achieve convenient operation , Improve the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

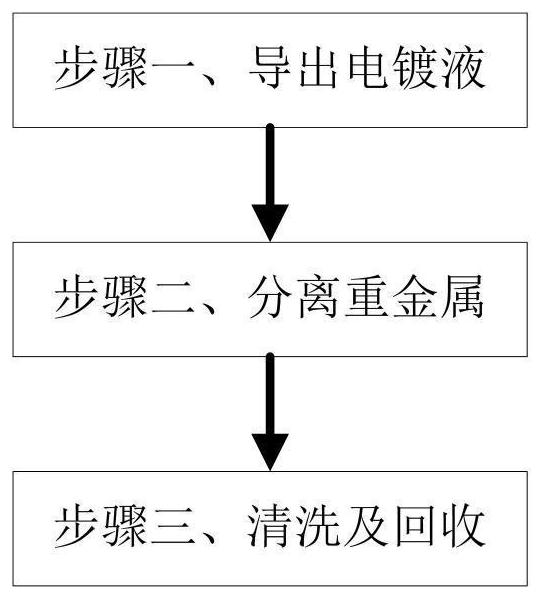

[0034] Such as figure 1 As shown, the present embodiment provides a method for recycling and reusing the alloy electroplating solution for environmental protection, comprising the following steps:

[0035] Step 1, exporting the electroplating solution: exporting the alloy electroplating solution after the electroplating is completed from the electroplating tank.

[0036] Step 2, separating heavy metals: separating heavy metals in the alloy electroplating solution by chemical agents, and taking out heavy metal compounds.

[0037] Step 3, cleaning and recovery: clean the heavy metal compound, and then recover the separated alloy electroplating solution.

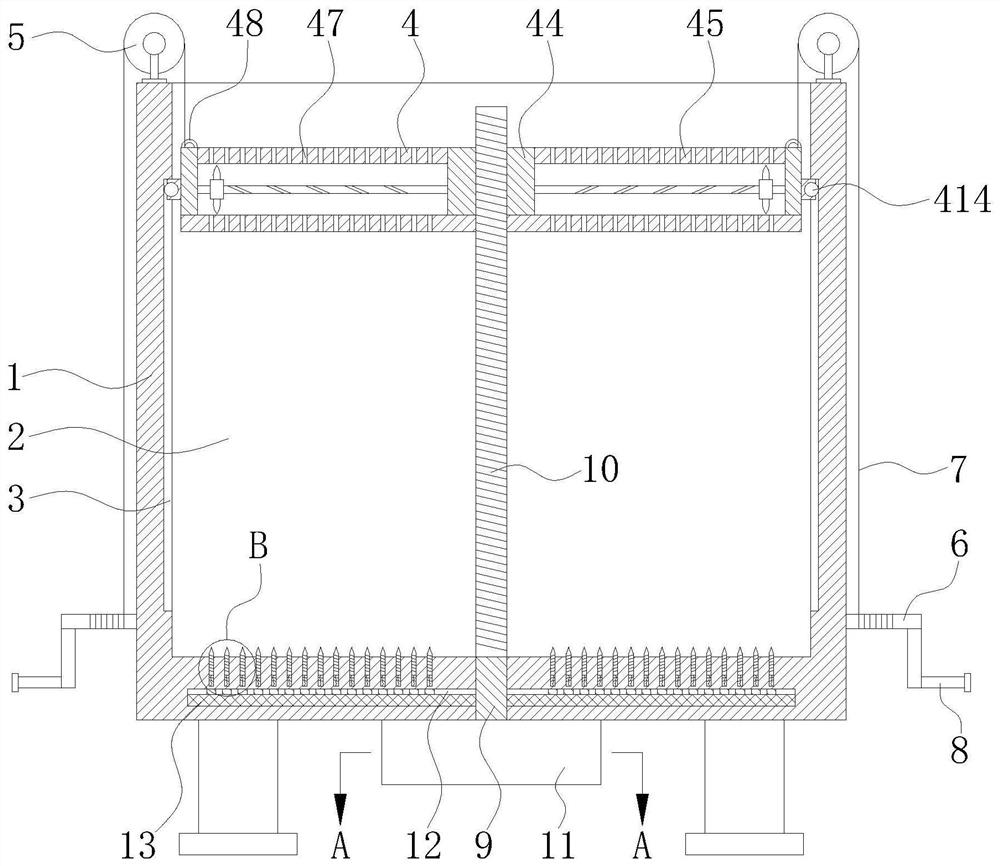

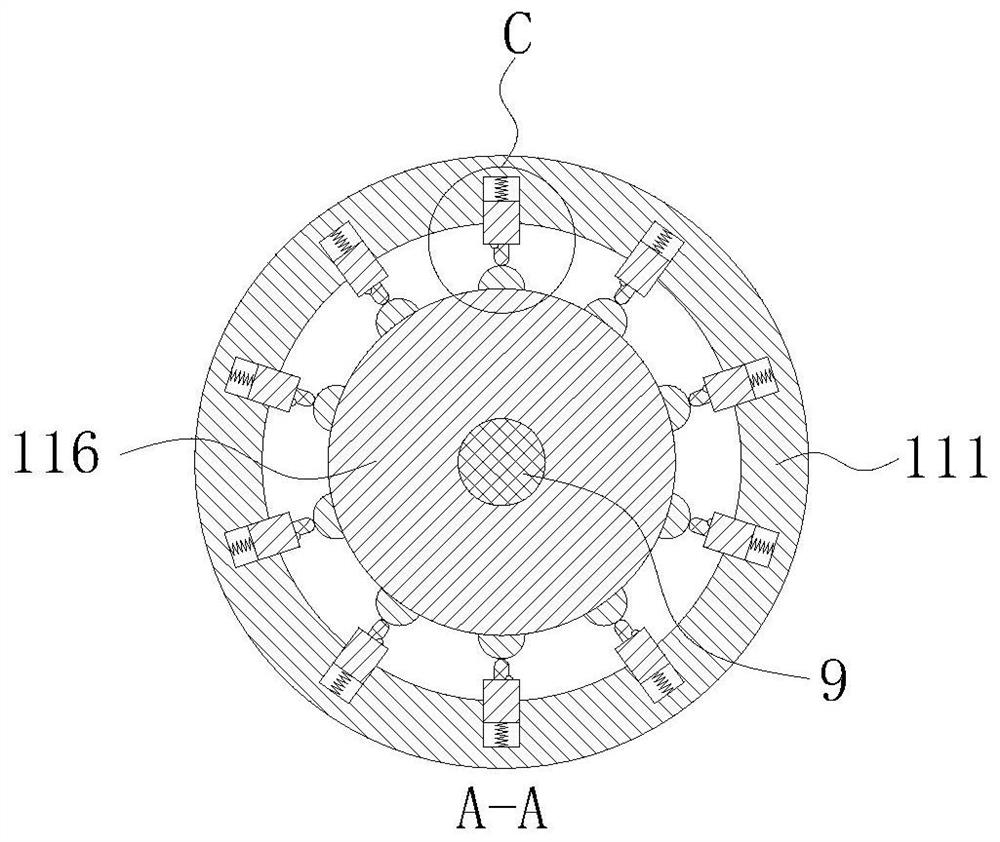

[0038] Among them, step two adopts such as Figure 2 to Figure 7 The recycling and reuse of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com