Assembly type revetment component and assembly type revetment construction method

A construction method and prefabricated technology, applied in the direction of foundation structure engineering, pier, quay wall, etc., can solve the problems of large environmental impact and low construction efficiency of cast-in-place reinforced concrete structures, achieve small environmental impact, shorten the on-site construction period, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

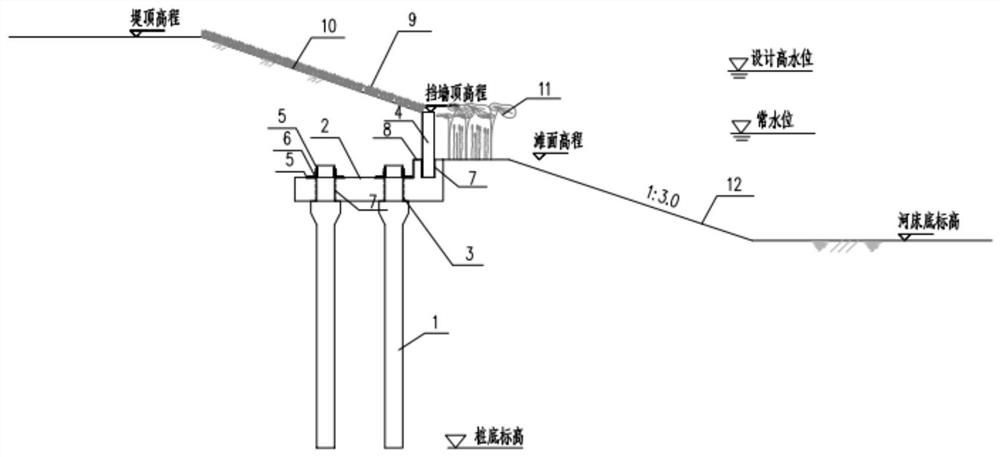

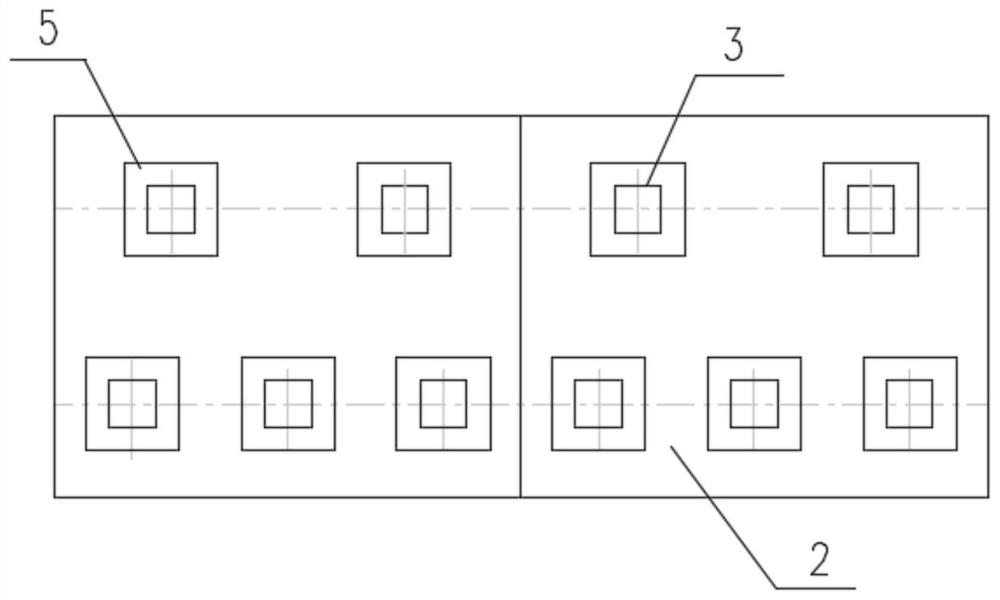

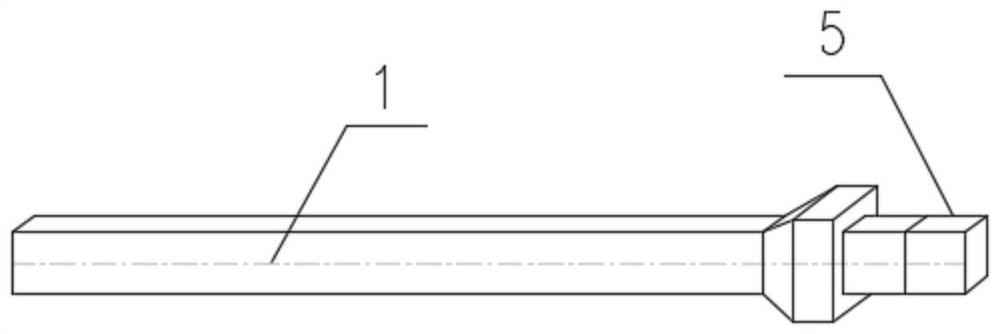

[0048] This embodiment discloses an assembled revetment component, such as Figure 1-4 As shown, the assembled revetment component includes a prefabricated square pile 1, a prefabricated bottom plate 2 and a prefabricated imitation wood pile 4. The lower part of the prefabricated square pile 1 is used to insert into the soil; the prefabricated bottom plate 2 is provided with a reserved hole 3, and the prefabricated bottom plate 2 is set on the top of the prefabricated square pile 1 through the reserved hole 3; a plurality of prefabricated imitation wood piles 4 are arranged side by side , the bottom of the prefabricated imitation wood pile 4 is connected to the top surface of the prefabricated bottom plate 2, and the top of the prefabricated imitation wood pile 4 extends upwards to form a retaining wall. figure 1 Revetment sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com