Self-resetting steel frame connecting joint capable of being quickly assembled

A technology for connecting nodes and self-resetting, applied in building components, earthquake resistance, building types, etc., can solve problems such as unfavorable component ductility development and energy consumption, many welded parts at node connections, residual deformation of components, etc., and achieve good engineering application prospects. , Superior seismic performance, the effect of reducing the welding part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

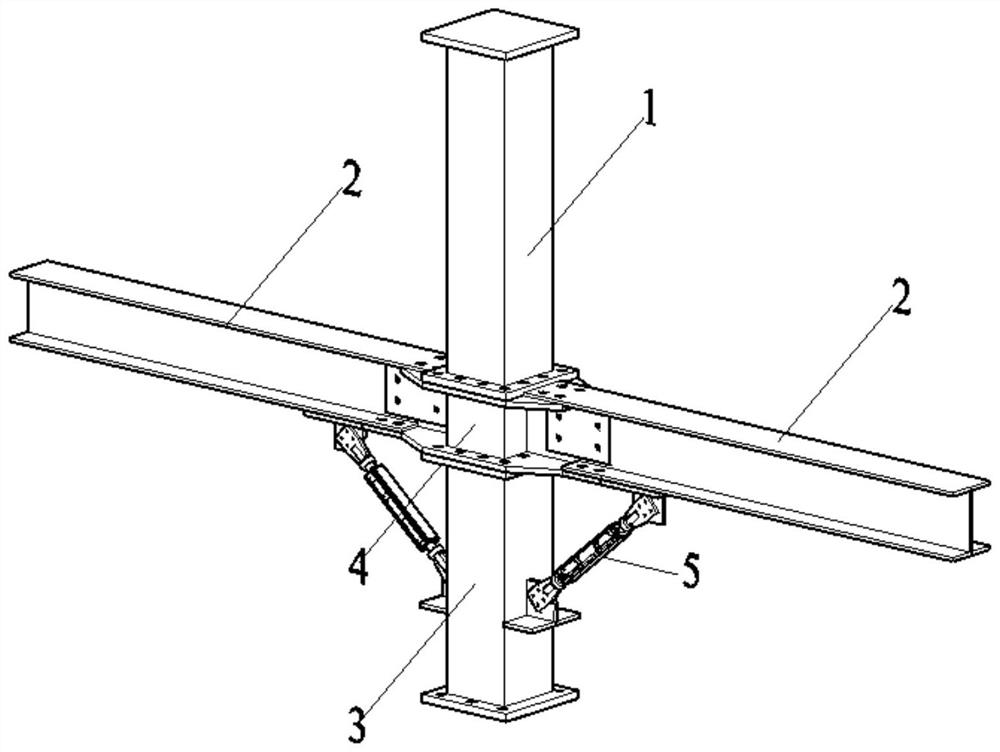

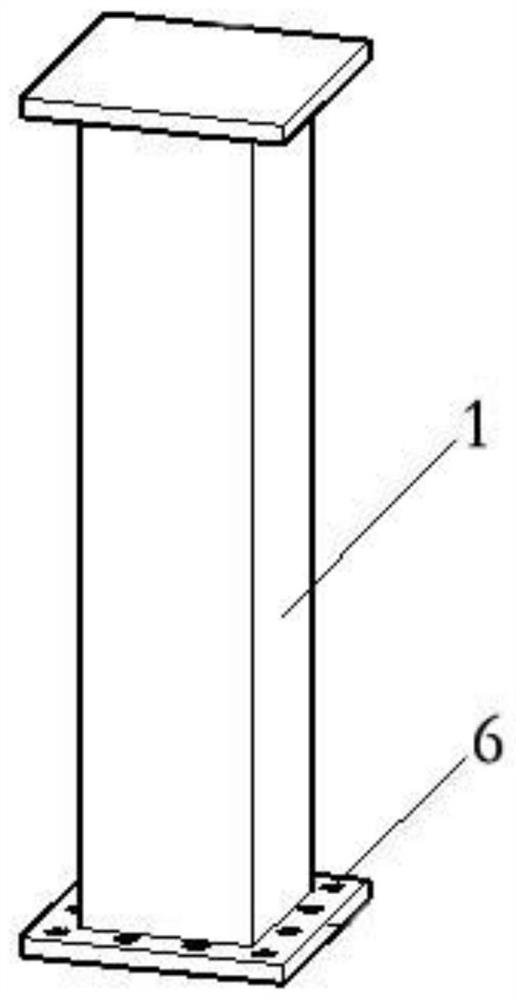

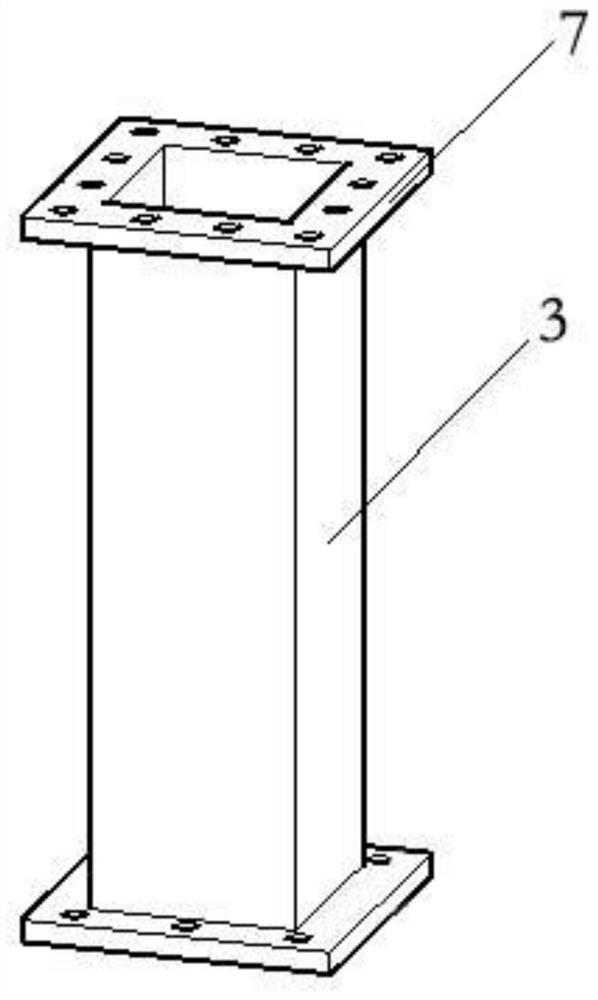

[0044] Such as figure 1 As shown, the present invention provides a fast-assembled self-resetting steel frame connection node, including upper column 1, middle column 4 and lower column 3 fixedly connected by bolts in sequence, and upper column 1, middle column 4, lower column 3 are hollow rectangular tubes, and two horizontally extending steel beams 2 connected by screws are installed on the center column 4, and the two steel beams 2 are symmetrically arranged along the central axis of the center column 4, so that the two steel beams 2 It is arranged in a cross with the middle column 4; a self-resetting support 5 is also supported between the lower column 3 and the steel beam 2, and one end of the self-resetting support 5 is fixed to the lower column 3 with bolts, and the other end of the self-resetting support 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com