Gas well shaft compound blockage treatment method

A composite and wellbore technology, applied in wellbore/well components, earthwork drilling, cleaning tools, etc., can solve problems such as difficult dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The wellbore of Yuanba x-1 well was clogged: before the clogging, the oil pressure was 32MPa, and the gas production was 450,000 m3 / day; after the clogging, the oil pressure was 25MPa, and the gas production was 300,000 m3 / day, with a continuous and slow downward trend.

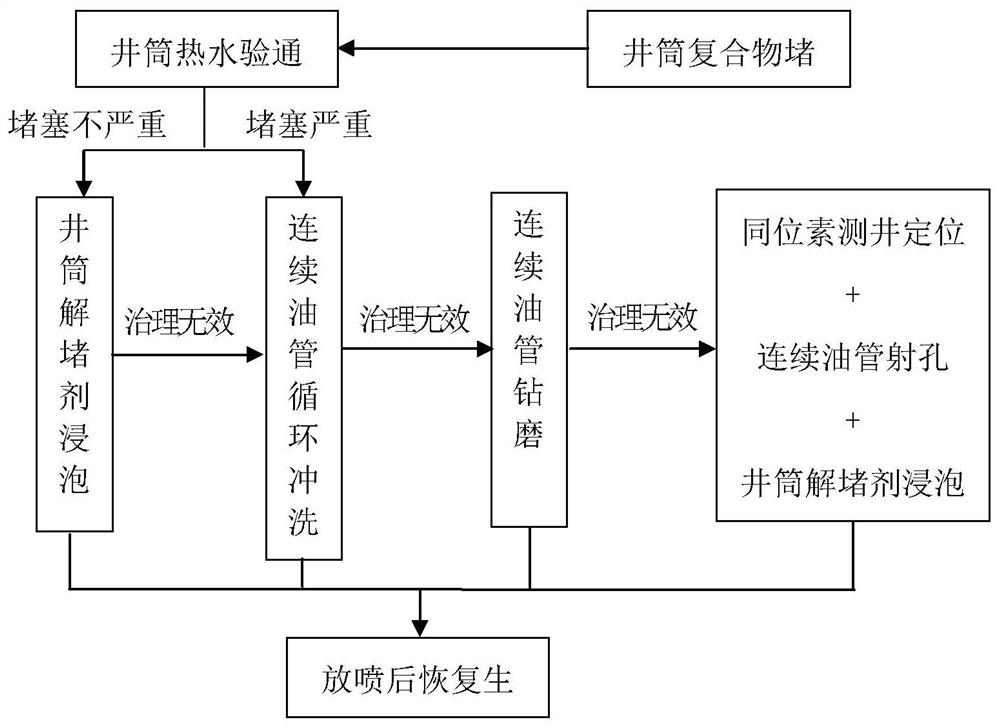

[0079] use as figure 1 The principle of the compound plugging removal process method shown is used for treatment, the same below. First, compound blockage treatment method: for the compound formed by organic bitumen and inorganic cuttings, first use hot water to verify wellbore blockage, displacement ≤ 1m 3 / min, pump hot water 10m from the wellhead to the wellbore 3 , observe the change of pump pressure. The results show that the pump pressure gradually decreases, indicating that the wellbore throttling is not serious, and the plugging solution soaking process is used to remove the plugging treatment. In displacement 0.5~1.0m 3 / min, in sequence, pump 10m from the wellhead to the wellbore 3 Inorg...

Embodiment 2

[0082] The wellbore of Yuanba x-2 well was blocked: before the blockage, the oil pressure was 35MPa, and the gas production was 500,000 cubic meters per day; after the blockage, the oil pressure was 22MPa, and the gas production was 250,000 cubic meters per day, and the downward trend gradually intensified.

[0083] Compound blockage treatment method: For the compound formed by organic asphalt and inorganic cuttings, first use hot water to verify wellbore blockage, displacement ≤ 1m 3 / min, pump hot water 10m from the wellhead to the wellbore 3 , observe the change of pump pressure. The pump pressure remains stable or even rises, which indicates that the wellbore is seriously blocked. The coiled tubing circulation flushing + plugging remover soaking process is used to remove the plugging treatment.

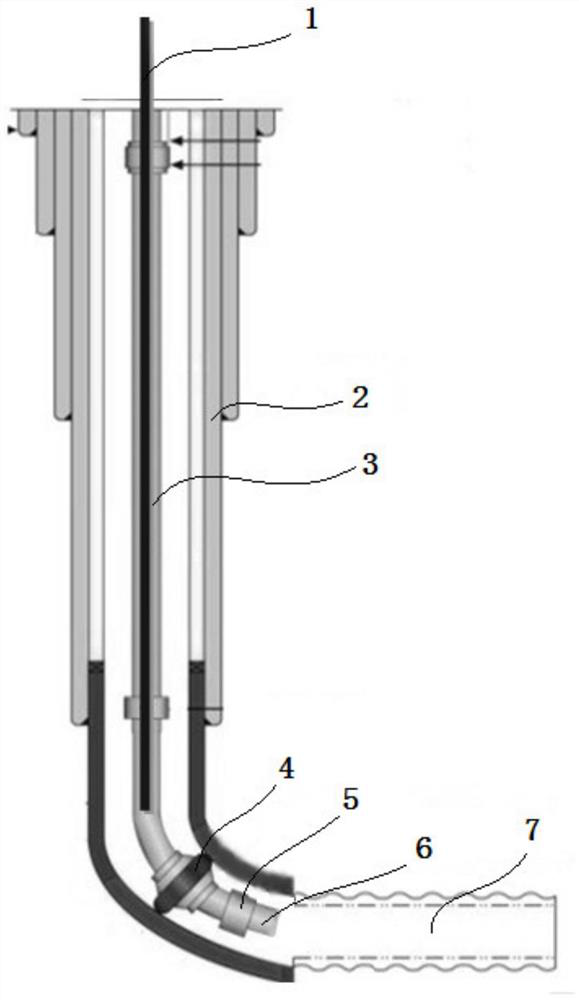

[0084] Under the condition of limited pressure of 70MPa, pump 35m into the wellbore 3 The flushing fluid plays the role of killing the well. A 1.75" coiled tubing string with a...

Embodiment 3

[0091] The wellbore of Yuanba x-3 well was clogged: before the clogging, the oil pressure was 40MPa, and the gas production was 550,000 m3 / day; after the clogging, the oil pressure was 30MPa, and the gas production was 300,000 m3 / day, showing a rapid decline trend.

[0092] Compound blockage treatment method: For the compound formed by organic asphalt and inorganic cuttings, first use hot water to verify wellbore blockage, displacement ≤ 1m 3 / min, pump hot water 10m from the wellhead to the wellbore 3 , observe the change of pump pressure. The pump pressure remains stable or even rises, which indicates that the wellbore is seriously blocked. The coiled tubing circulation flushing + plugging remover soaking process is used to remove the plugging treatment.

[0093] Under the condition of limited pressure of 70MPa, pump 35m into the wellbore 3 The flushing fluid plays the role of killing the well. A 1.75" coiled tubing string with a nozzle is run in the wellbore string, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com