Oil return system and oil return method thereof

A technology of oil return system and engine oil, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc. It can solve the problems of low reliability, large size, and easy blockage of one-way valves, etc., and achieves simple structure and increased layout freedom degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, an oil return system and an engine including the oil return system are proposed. Among them, the oil return system can prevent the oil from being sucked back into the oil-air separator from the oil pan, and can ensure that no air will enter the negative pressure oil filter, and has the characteristics of simple structure and high reliability.

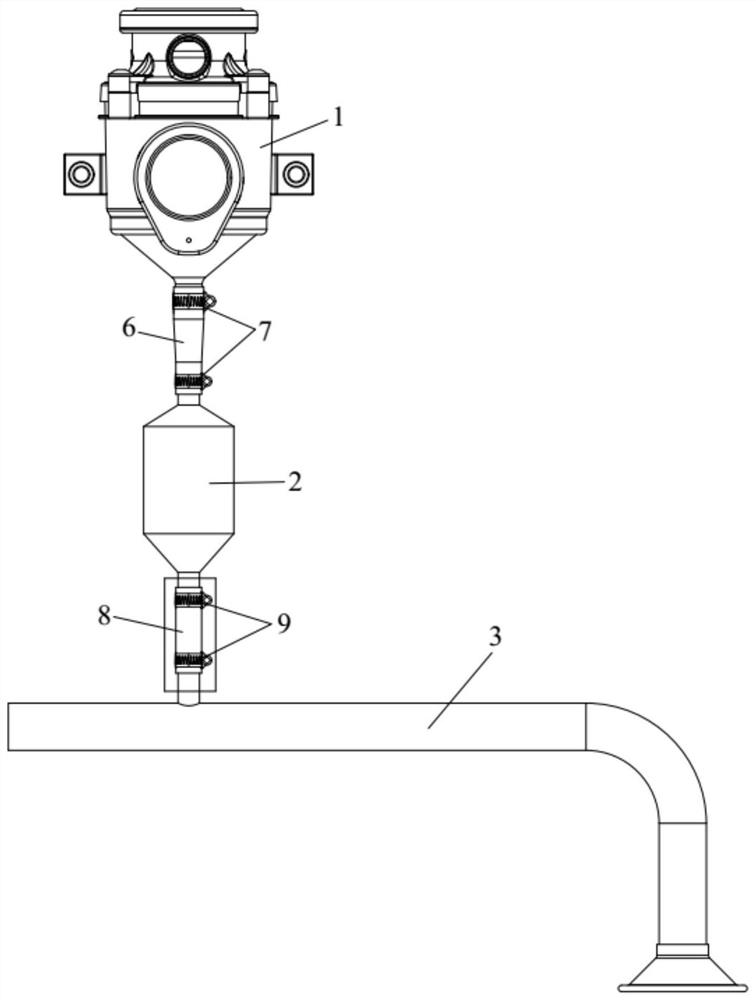

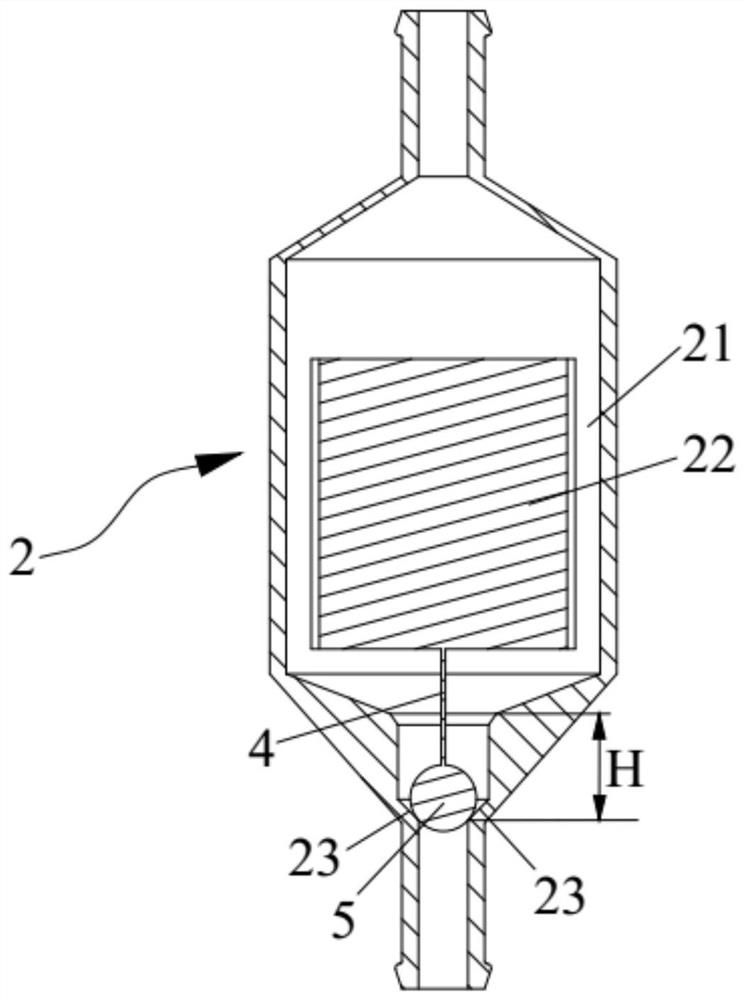

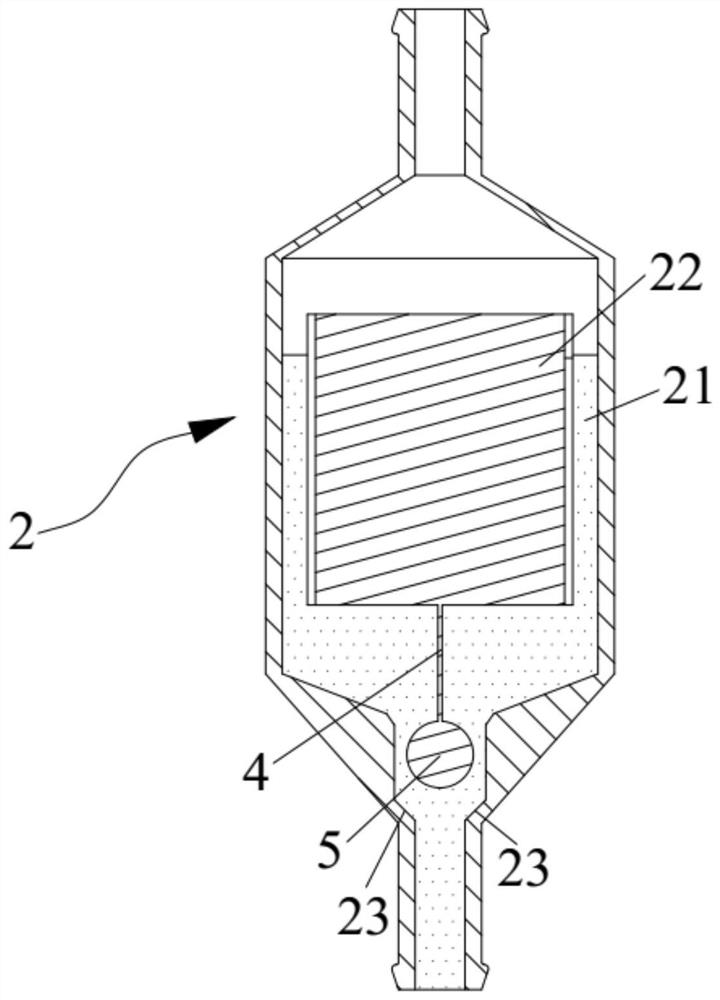

[0040] Specifically, such as figure 1As shown, the oil return system includes an oil-air separator 1 , a negative pressure oil filter 3 and a one-way float valve 2 . Among them, one end of the oil-gas separator 1 is connected with the crankcase to separate the engine oil in the mixed gas discharged from the crankcase; the one-way float valve 2 is connected with the oil-gas separator 1 and the negative pressure oil filter 3, and the negative pressure oil collector The other end of the filter 3 is inserted under the oil level of the oil pan, and the negative pressure oil filter 3 is used to filter the oil in th...

Embodiment 2

[0052] In this embodiment, a method of oil return using the oil return system in Embodiment 1 is proposed. The oil return method of the oil return system includes the following steps:

[0053] S1, discharge part of the oil in the oil storage chamber 21, so that the gravity ball 5 moves vertically downward under the action of its own gravity to fit the sealing surface 23, so as to block the one-way float valve 2, so that the one-way float valve 2 is isolated from the negative pressure oil filter 3, thereby preventing the gas in the oil-gas separator 1 from entering the negative pressure oil filter 3.

[0054] S2, the oil separated by the oil-gas separator 1 gradually flows into the oil storage chamber 21 until the float 22 can drive the gravity ball 5 to move vertically upward under the action of the buoyancy of the oil, so that the gravity ball 5 is separated from the sealing surface 23 , to open the one-way float valve 2, so that the oil in the oil storage chamber 21 flows in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com