Overhauling robot with rollover prevention function for pipeline overhauling

An anti-rollover and robot technology, applied to semiconductor devices, tube components, and special tubes of light-emitting elements, can solve the problems of robots falling down, inconvenient application, and difficult internal inspection of pipelines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

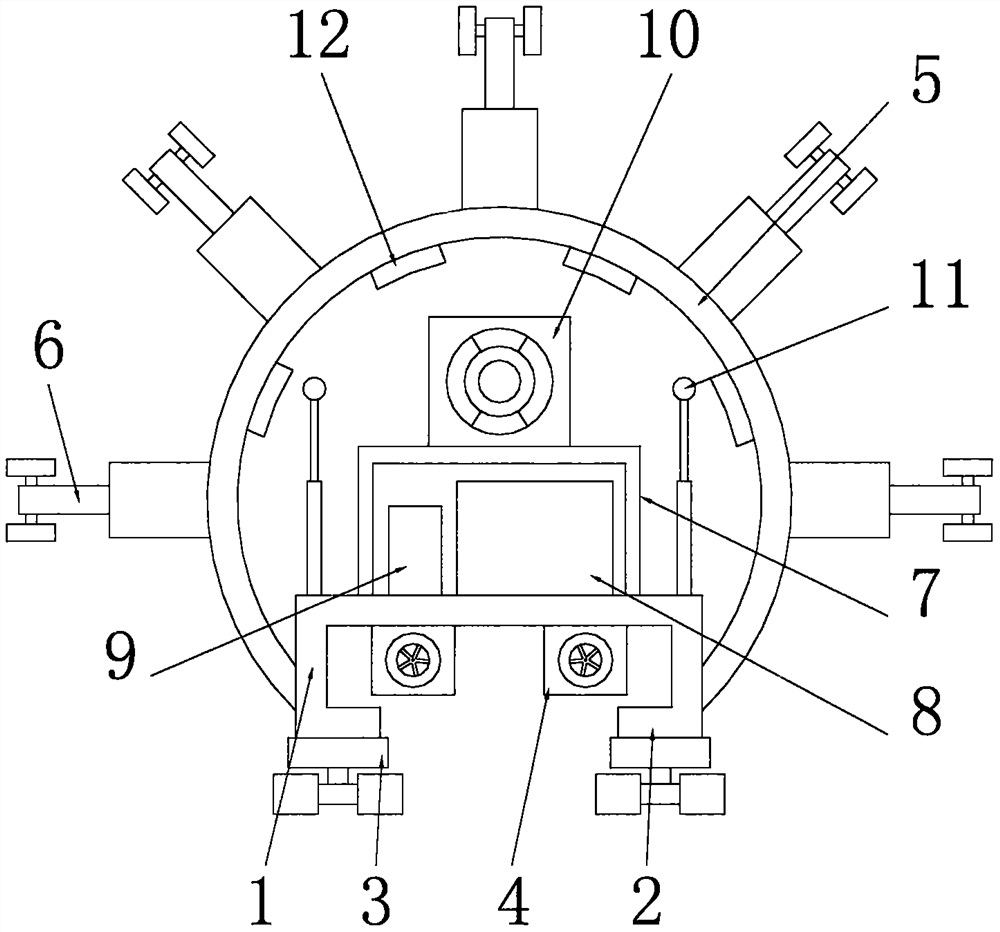

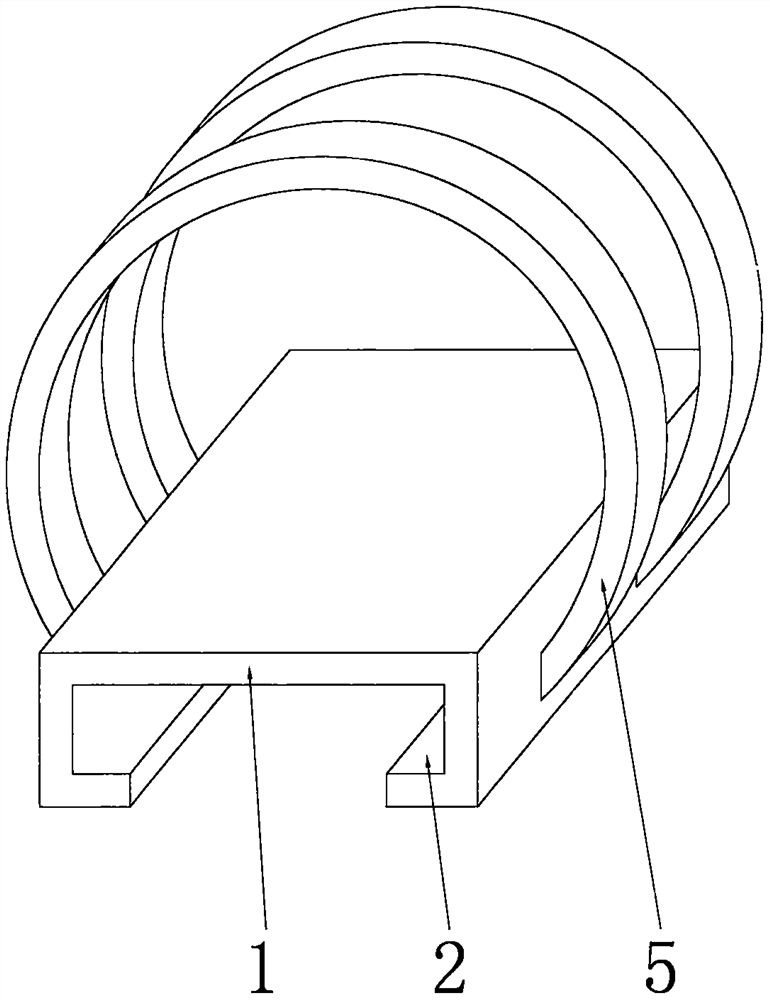

[0036] See Figure 1-4 , a maintenance robot for pipeline maintenance with anti-rollover function, comprising an underframe 1, the underframe 1 is an inverted U-shaped structure, the bottom end of the underframe 1 is left and right symmetrically provided with a mounting plate 2, the underframe 1 and The mounting plates 2 are integrally formed, and the length of the chassis 1 is the same as that of the mounting plates 2. The bottom end of the mounting plate 2 is provided with an electric drive assembly 3, which is a crawler-type drive mechanism. The chassis 1 can be driven to walk in the pipeline by using the electric drive assembly 3, and it can overcome the adaptability of various terrains;

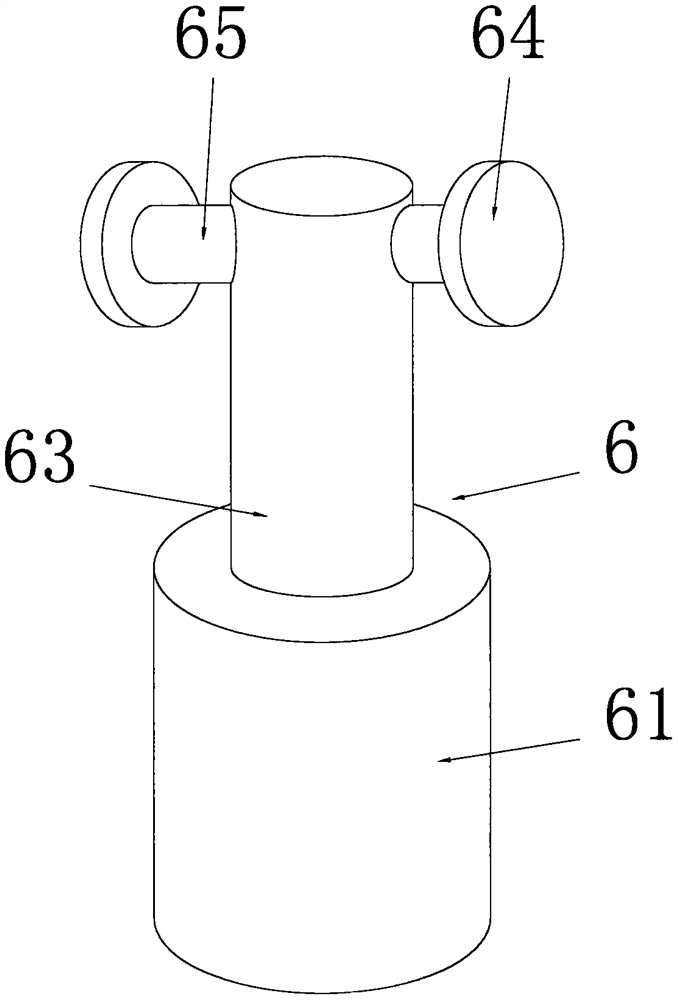

[0037] The top of the underframe 1 is provided with a stand 7 and two wireless transmission devices 11, the stand 7 is fixed in the middle of the top of the underframe 1, and the two wireless transmission devices 11 are symmetrically arranged on the stand 7 The left and right sides of t...

Embodiment 2

[0043] See Figure 5 The difference from Embodiment 1 is that the dredging assembly 4 includes a dredging motor 41, the dredging motor 41 is fixedly connected to the inner cavity top wall of the chassis 1, and the dredging motor 41 is connected to the dredging shaft 42 in rotation. One end of dredging shaft 42 away from dredging motor 41 is fixedly connected with dredging drill 43, and the outer circular surface of dredging shaft 42 is evenly provided with some cleaning brushes 44, and dredging assembly 4 drives dredging shaft 42 high-speed rotations by dredging motor 41, and then utilizes dredging The shaft 42 drives the dredging drill 43 to rotate at a high speed, and the high-speed rotating dredging drill 43 can be used to break the barrier, and the high-speed rotating cleaning brush 44 can be used to further expand and clean the pipeline to clear the internal blockage of the pipeline; at the same time, it can also remove foreign matter on the bottom wall of the pipeline , ...

Embodiment 3

[0045] See Figure 6-7 , the difference from Embodiment 1 is: the image-collecting assembly 10 includes a seat plate 101, the seat plate 101 is fixedly connected to the top of the stand 7, and the top of the seat plate 101 is provided with an angle frame 102 and a power frame 103, Described angle frame 102 and power frame 103 all are U-shaped structures, and the top end face of described power frame 103 is higher than the top surface of angle frame 102, and power frame 103 is located at the right side of angle frame 102, and the top end face of described angle frame 102 The inner cavity is provided with an angle rod 105, and the angle rod 105 is hinged on the inner cavity top wall of the angle frame 102 through the hinge seat 104, and the inner cavity top wall of the power frame 103 is fixedly connected to the electric telescopic device 106, and the electric telescopic device The bottom end of the second telescopic rod 107 on the 106 is hinged on the top of the angle rod 105, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com