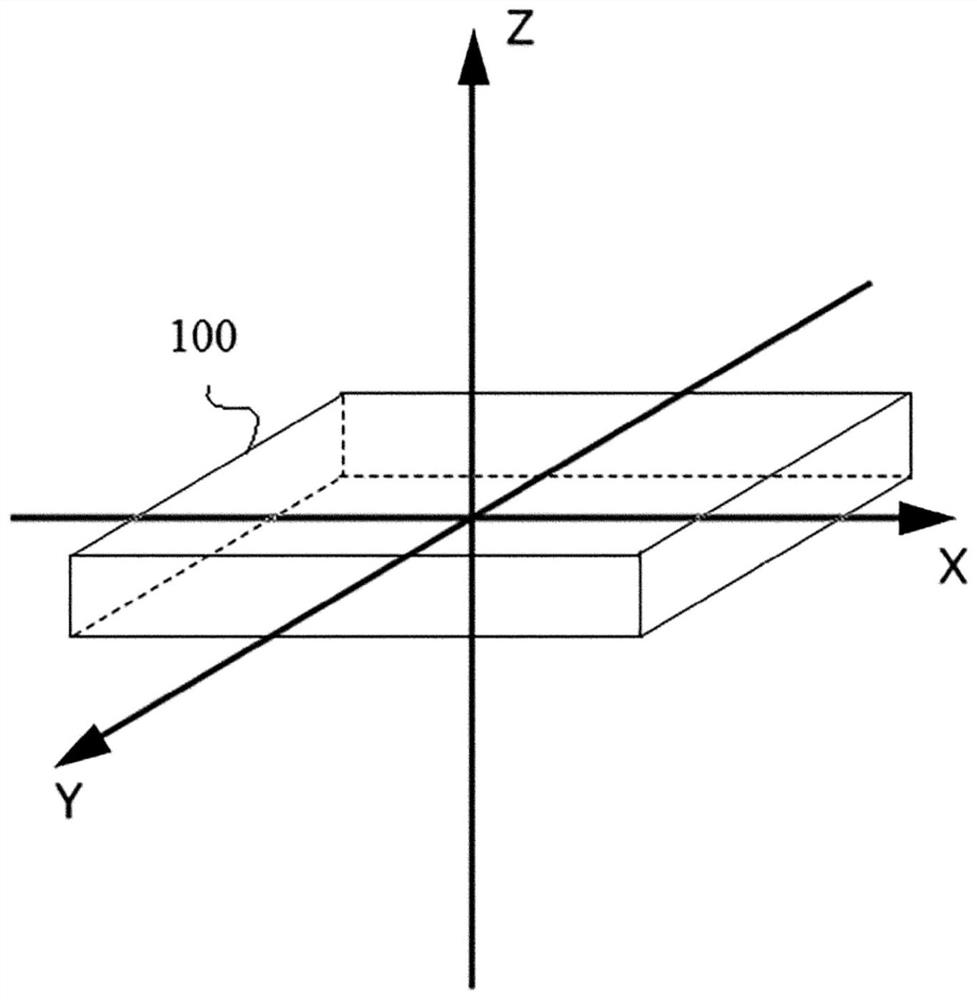

Laminated film

A technology for laminating films and base films, applied in coatings, instruments, radiation-absorbing coatings, etc., can solve problems that affect durability and optical properties, and polymerization cannot be properly performed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0156] Preparation Example 1. Preparation of Polymerizable Liquid Crystal Composition A

[0157] A polymerizable liquid crystal composition was prepared using LC1057 liquid crystal of BASF Company as a forward dispersion polymerizable liquid crystal compound and a liquid crystal compound of the following formula A as a reverse dispersion liquid crystal compound. The forward dispersion polymerizable liquid crystal compound has R(450) / R(550) at a level of about 1.09 to 1.11 and R(650) / R(550) at a level of about 0.93 to 0.95, formula A The liquid crystal compound has R(450) / R(550) at a level of about 0.84 to 0.86 and R(650) / R(550) at a level of about 1.01 to 1.03. R(450), R(550) and R(650) are, respectively, for wavelengths of 450 nm, 550 nm and In-plane retardation of light at 650nm. The in-plane retardation can be measured by a known method, for example, it can be measured by polarimetry using Axoscan (Axometrics) as a birefringence meter. A method of forming a retardation l...

preparation example 2

[0183] Preparation Example 2. Preparation of Polymerizable Liquid Crystal Composition B

[0184] A polymerizable liquid crystal composition B was prepared in the same manner as in Preparation Example 1, except that a liquid crystal compound of the following formula B was used as the reverse dispersion polymerizable liquid crystal compound. The liquid crystal compound of formula B has R(450) / R(550) at a level of about 0.81 to 0.83 and R(650) / R(550) at a level of about 1.01 to 1.03. R(450), R(550), and R(650) are in-plane retardations for light of wavelengths of 450 nm, 550 nm, and 650 nm as measured relative to a retardation layer formed by using the polymerizable liquid crystal compound of Formula B alone.

[0185] [Formula B]

[0186]

[0187] Here, the compound of formula B was obtained by obtaining a compound represented by the following formula A9 in the same manner as in Preparation Example 1, and then replacing the hydrogen atom bonded to the nitrogen atom of the com...

preparation example 3

[0191] Preparation Example 3. Preparation of Polymerizable Liquid Crystal Composition C

[0192] A polymerizable liquid crystal composition was prepared by applying: the reverse dispersion polymerizable liquid crystal compound of the formula A in the above Preparation Example 1, the same photoinitiator as that used in Preparation Example 1, and Ultraviolet absorber (Orient Chemical Industries, BONASORBUA-3912) having a maximum absorption wavelength range of about 380 nm to 390 nm. The reverse dispersion polymerizable liquid crystal compound of formula A, the photoinitiator and the ultraviolet absorber are combined in a solvent (ring Pentanone) to prepare polymerizable liquid crystal composition C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com