Printing and dyeing wastewater advanced treatment system

A technology for advanced treatment of printing and dyeing wastewater, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sewage treatment equipment, etc., can solve the problems of wastewater being difficult to flow down and blocking meshes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

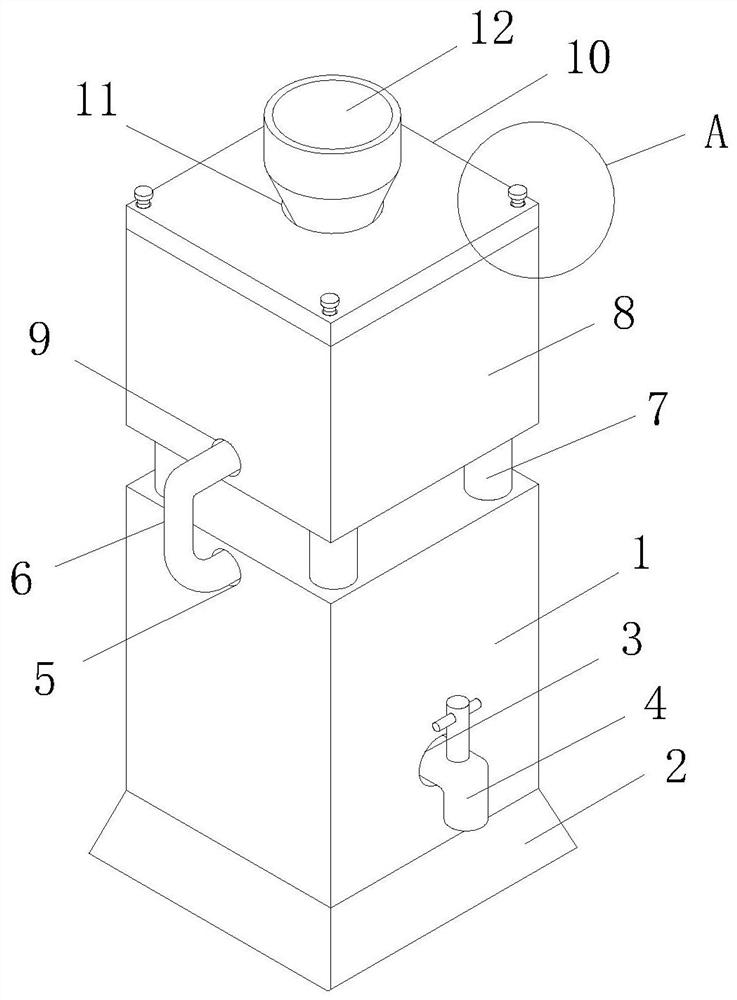

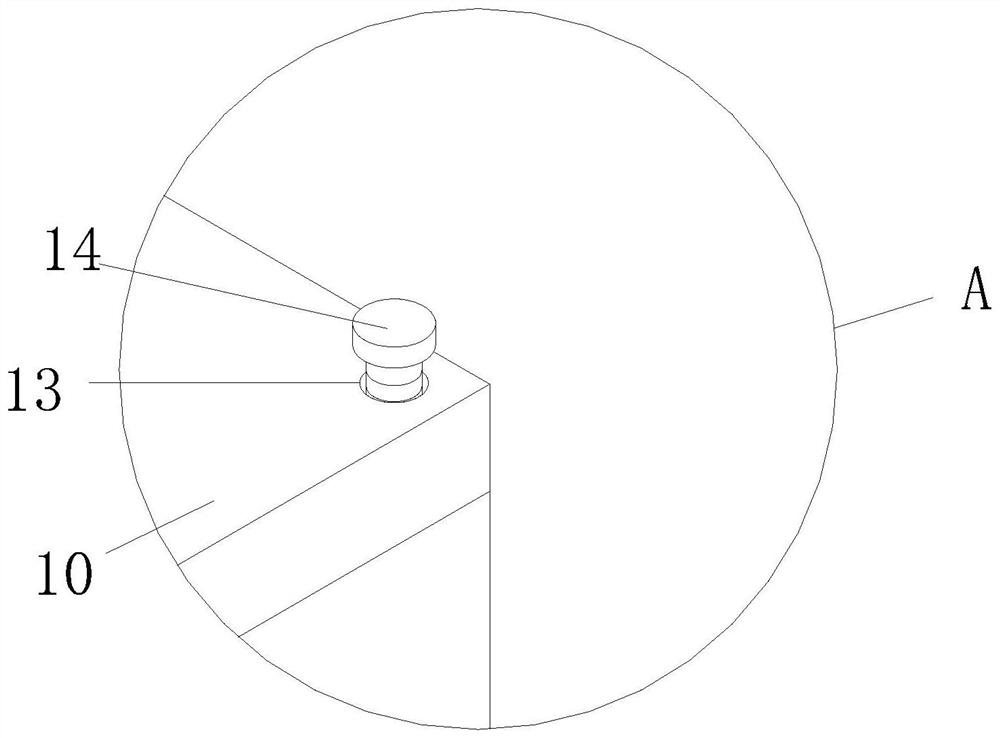

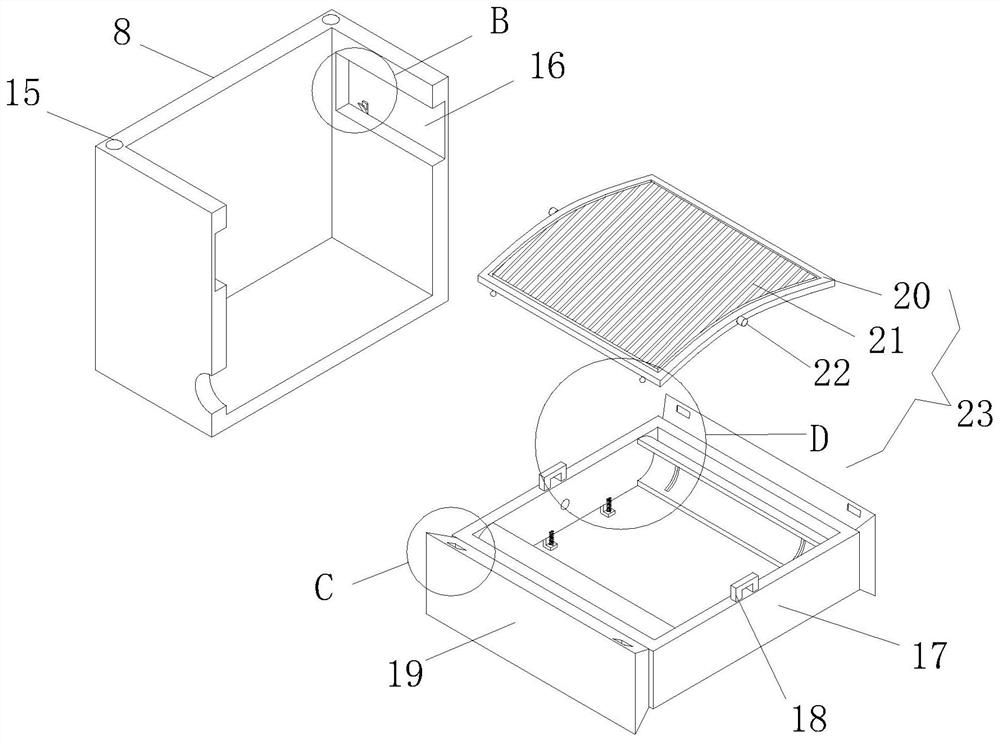

[0029] Embodiment: a kind of printing and dyeing wastewater advanced treatment system, such as Figure 1-Figure 9As shown, the adsorption tower 1 is included, the adsorption tower 1 is a rectangular hollow structure, the lower wall of the adsorption tower 1 is fixed with a base 2, the base 2 is a quadrangular truss-shaped structure, and the front wall of the adsorption tower 1 is provided with a water outlet 3 near the lower end. , the water outlet 3 is a circular through hole, the inside of the water outlet 3 is provided with a water outlet pipe 4, the water outlet pipe 4 is an L-shaped hollow pipe, the water outlet pipe 4 and the water outlet 3 are plugged together, and the outer wall of the water outlet pipe 4 is provided with The valve, the rear wall of the adsorption tower 1 is provided with a water inlet 5 near the upper end, the water inlet 5 is a circular through hole, and the four corners of the upper wall of the adsorption tower 1 are fixedly equipped with supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com