Injection pump with inner flow guide structure

A technology of internal diversion and jet pumps, which is applied to jet pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of large energy loss fluid impacting the pump body 1 noise, etc., and achieve easy intelligent control , less disorderly impact, stable fluid pressure fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

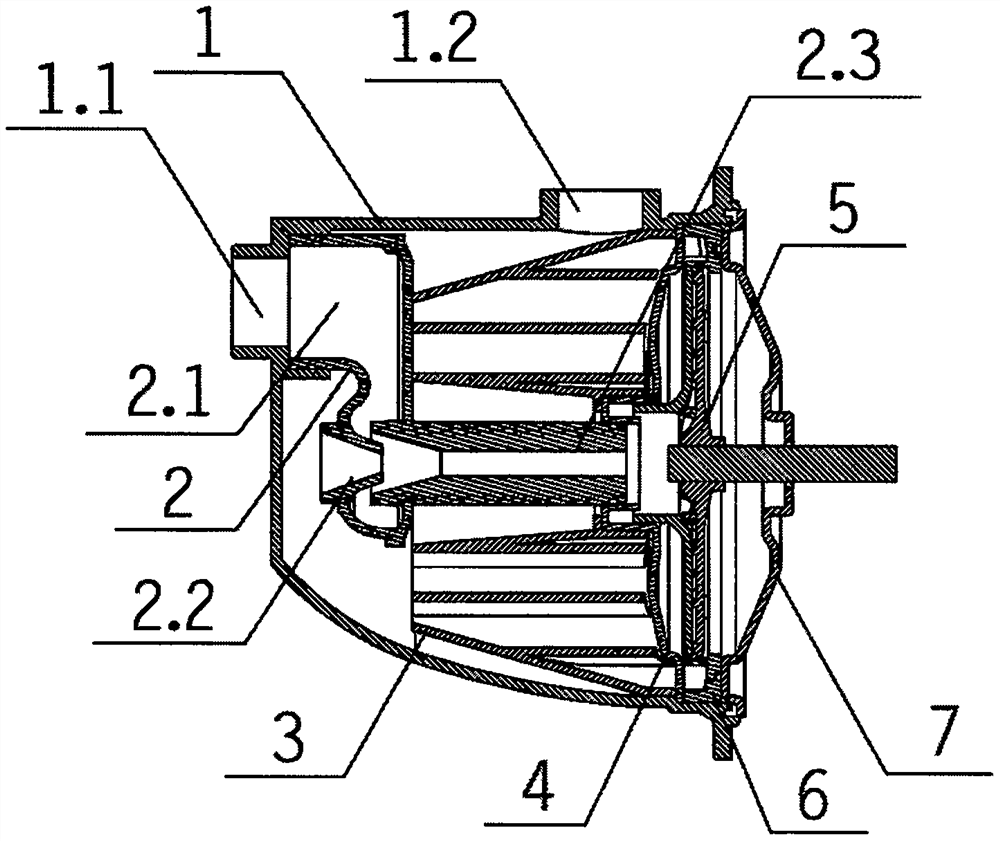

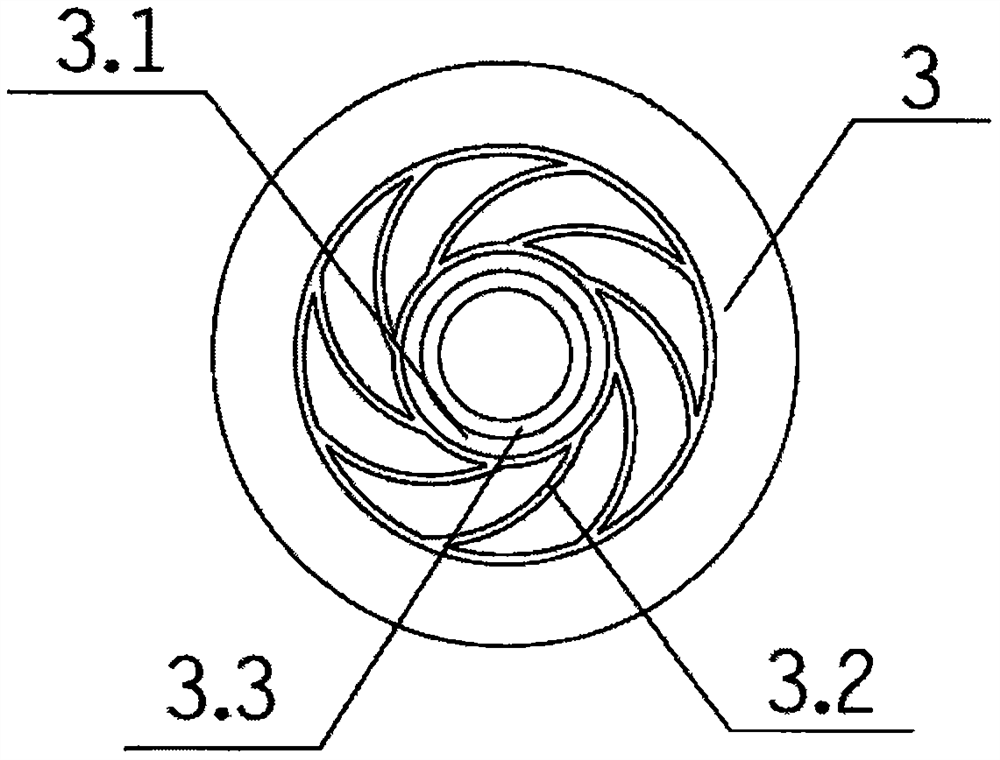

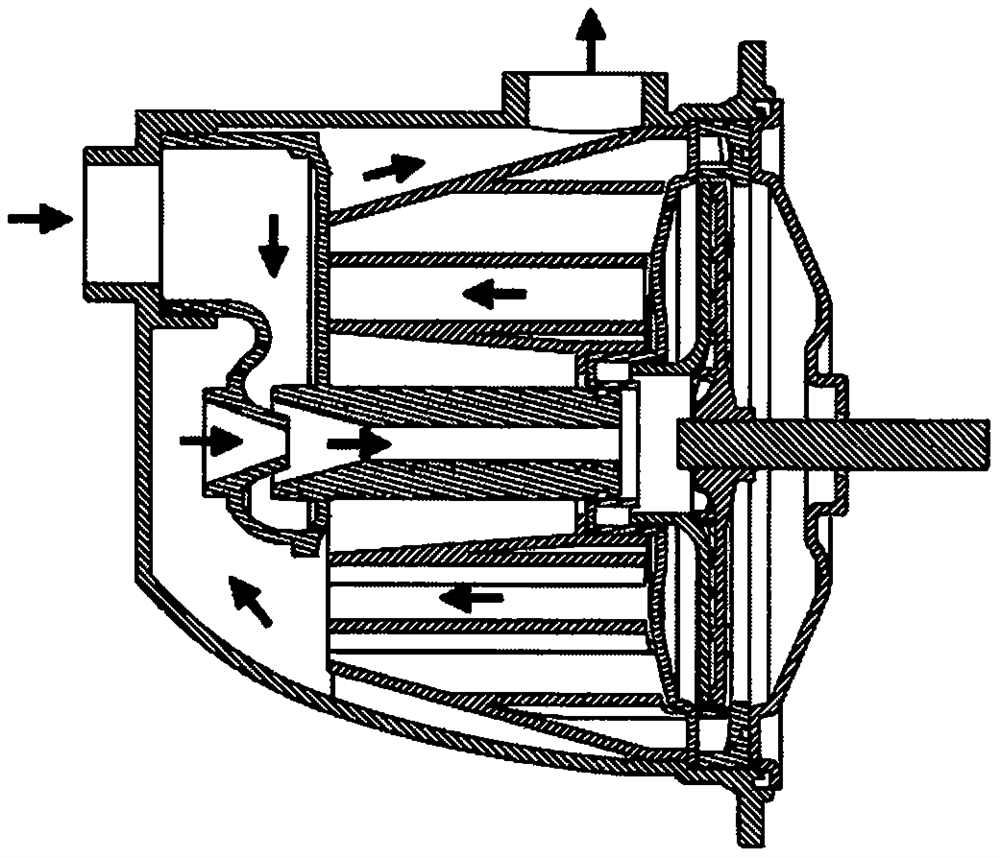

[0022] Such as figure 1 , a jet pump provided with an internal diversion structure, the pump body 1 is cylindrical with an open rear end. In the pump body 1, an injector 2, an inner deflector 3, a forward swirl cover 4, an annular liquid guide 6, an impeller chamber 5 and a rear swirl cover 7 are provided in sequence from front to back. A pump body water inlet 1.1 is provided near the top of the front end of the pump body 1, and a pump body water outlet 1.2 is provided above the rear end of the pump body 1.

[0023] The injector 2 is composed of an injector water inlet 2.1, a nozzle 2.2, and a nozzle pipe 2.3. The injector 2 is fixed by connecting the pump body water inlet 1.1 inside the injector water inlet 2.1 of the head, and the lower end of the injector water inlet 2.1 is provided with Conical nozzle 2.2, the rear end of the nozzle 2.2 is provided with a cylindrical spray pipe 2.3 concentric with it. The end of the nozzle pipe 2.3 is connected to the connecting channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com