Probe card maintenance and correction method

A calibration method and probe card technology, which is applied to the parts of electrical measuring instruments, measuring devices, instruments, etc., can solve the problems of small probe size, high time cost training and proficiency, and small operating window, so as to reduce the Correction difficulty, reducing training requirements and operating difficulty, improving the effect of operating window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

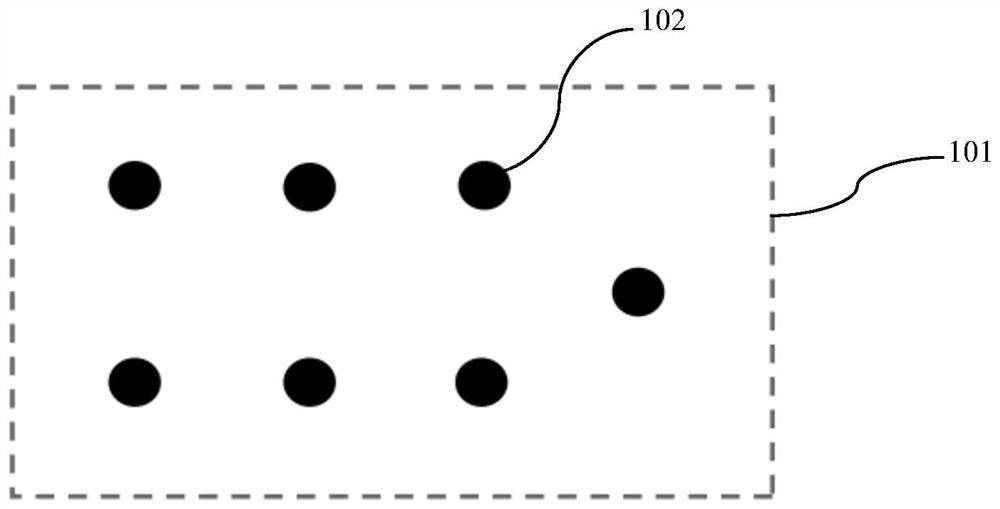

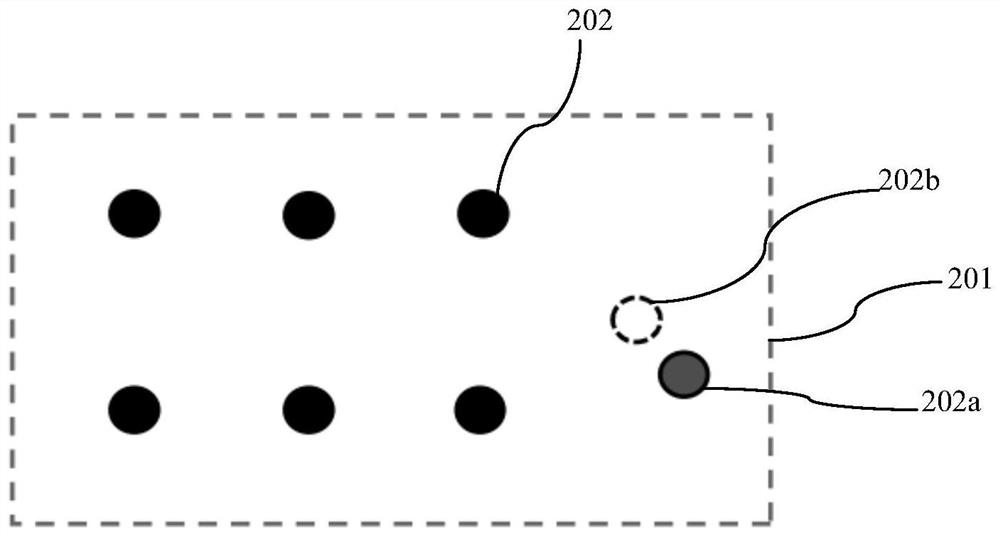

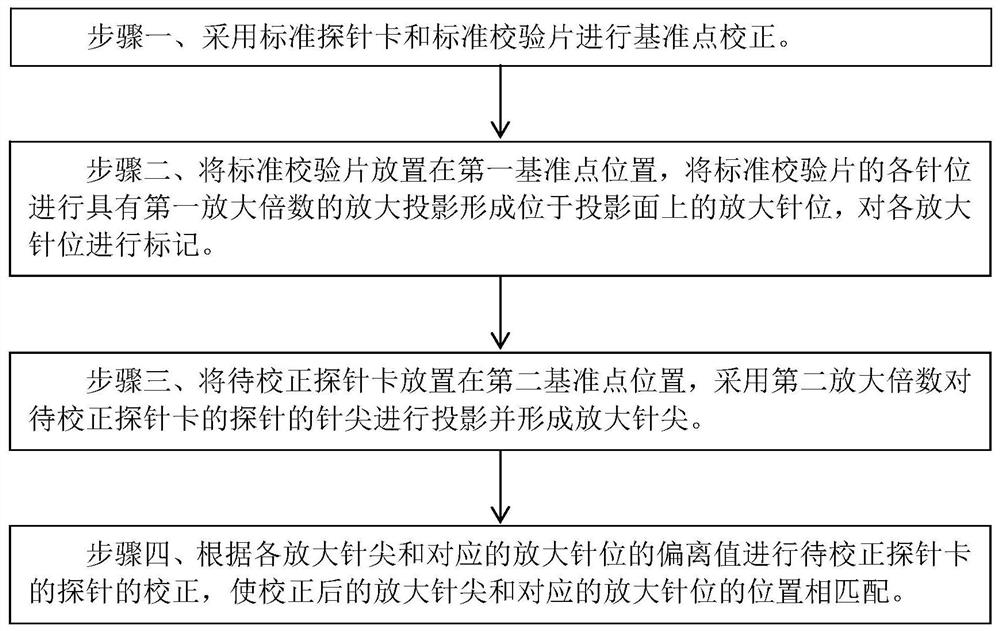

[0033] Such as figure 2 As shown, it is a flow chart of the maintenance and calibration method of the probe card in the embodiment of the present invention; image 3 As shown, it is a schematic diagram of the needle position 2 projection of the standard calibration sheet 1 in step 2 of the method of the embodiment of the present invention; Figure 4 As shown, it is a schematic diagram of the projection of the probe tip 6 of the probe card 5 to be calibrated in Step 3 of the method of the embodiment of the present invention; the maintenance and calibration method of the probe card of the embodiment of the present invention includes the following steps:

[0034] Step 1: Use the standard probe card and the standard calibration sheet 1 to perform reference point calibration to obtain the first reference point position of the standard calibration sheet 1 and the second reference point position of the probe card 5 to be calibrated.

[0035] The standard probe card has a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com