Carbon cloth with vertical graphene with uniform distribution of cobalt particles and its preparation method and application

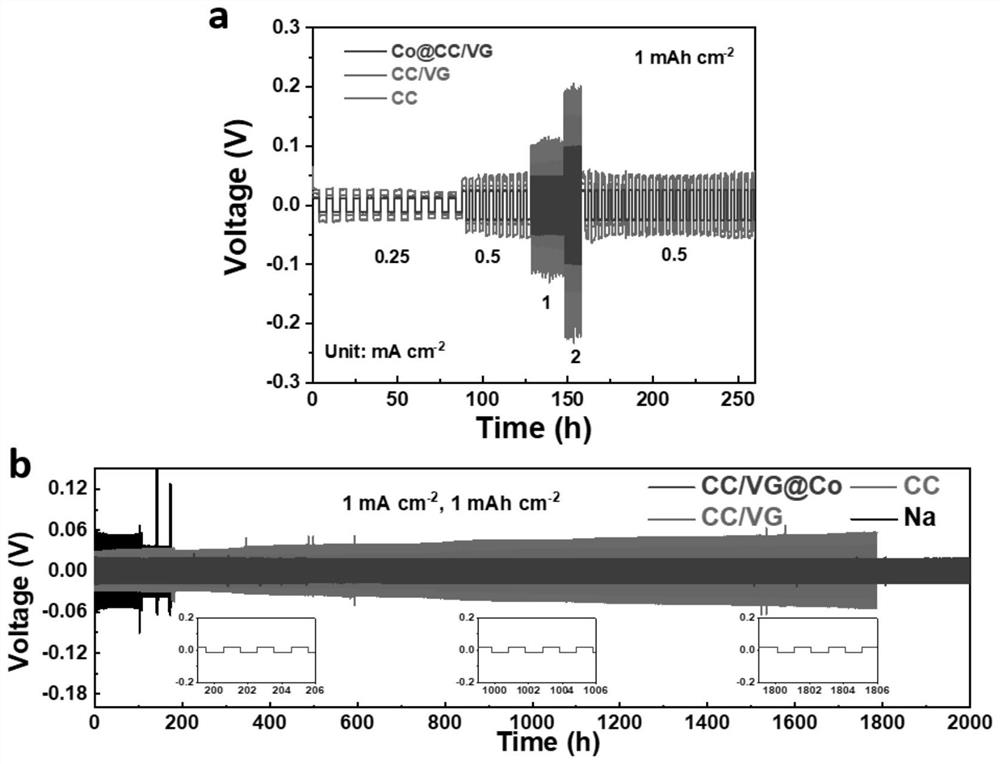

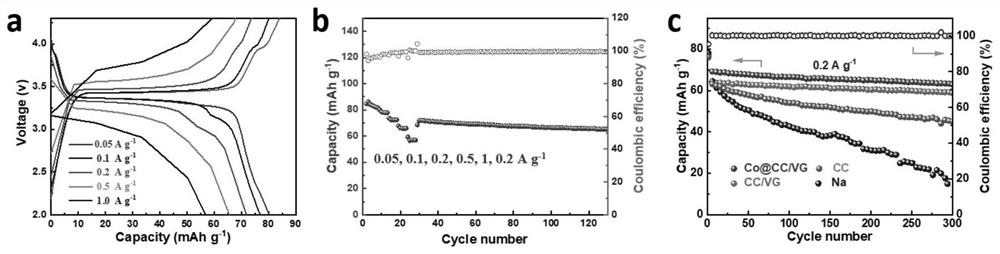

A technology with uniform particles and graphene, applied in the direction of active material electrodes, structural parts, electrical components, etc., can solve the problems of many dendrite growth, large volume effect, and low Coulomb efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

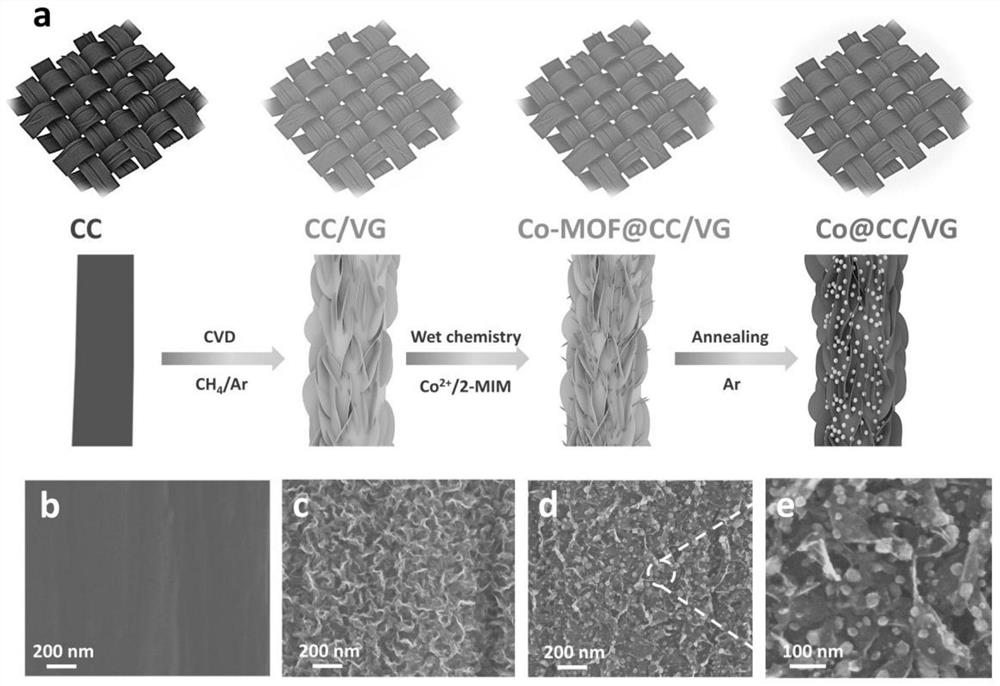

[0033] The present embodiment provides a kind of synthetic method of the carbon cloth that the long vertical graphene of cobalt particle is uniformly distributed, and it comprises the following steps:

[0034] (a) Arrange the carbon in the CVD furnace, vacuumize, feed 100sccm argon and 10sccm methane, grow vertical graphene at 500-600°C by 80w PECVD to obtain the first carbon cloth, and add 0.493g 2-methyl Imidazole and 0.218g cobalt nitrate were uniformly dispersed in 20ml water respectively, and mixed to obtain the first solution;

[0035] (b) Put the first carbon cloth into the first solution with magnetic stirring, react for 4-5h to grow Co-MOF, take it out, wash it with deionized water, and dry it to obtain the second carbon cloth; The carbon is arranged in a tube furnace, and argon-protected annealing is used to obtain a carbon cloth with vertical graphene with evenly distributed cobalt particles (first burn at 400°C for 3 hours, then burn at 700°C for 8 hours, and the h...

Embodiment 2

[0043] The present embodiment provides a kind of synthetic method and the application thereof of the carbon cloth that the long vertical graphene of cobalt particle is uniformly distributed, and it is basically consistent with embodiment 1, and difference only is: in step (a), the cobalt nitrate The amount added was 0.175g.

Embodiment 3

[0045] The present embodiment provides a kind of synthetic method and the application thereof of the carbon cloth that the long vertical graphene of cobalt particle is uniformly distributed, and it is basically consistent with embodiment 1, and difference only is: in step (a), the cobalt nitrate The amount added was 0.262g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com