Auxiliary-operating weeding machine

A weeder and end face technology, applied in auxiliary drive devices, harvesters, transportation and packaging, etc., can solve the problems of untidy cutting of weeder, laborious uphill of weeder, hidden safety hazards, etc., and achieve simple structure, neat and efficient weeding, The effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

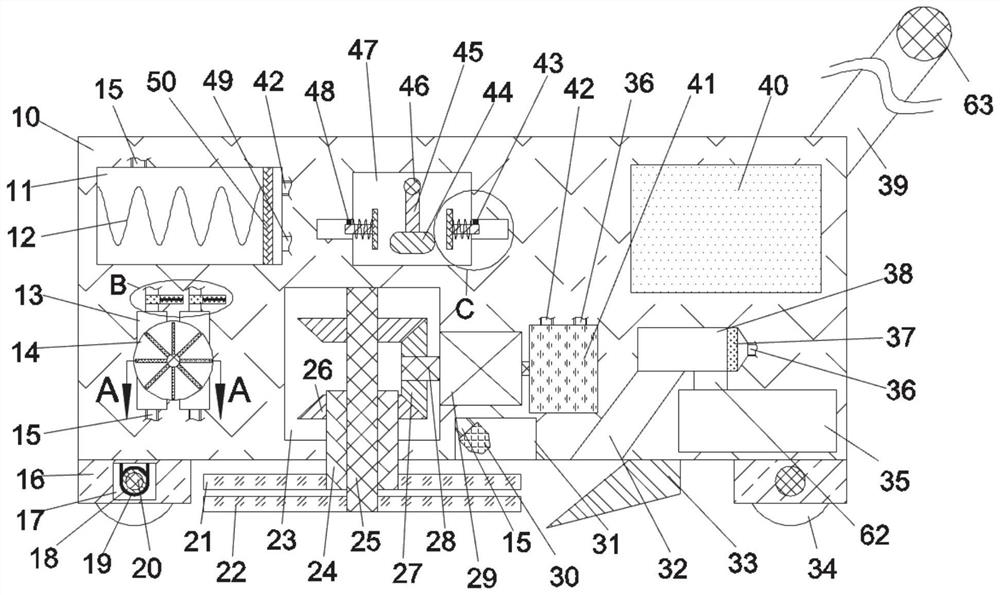

[0015] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

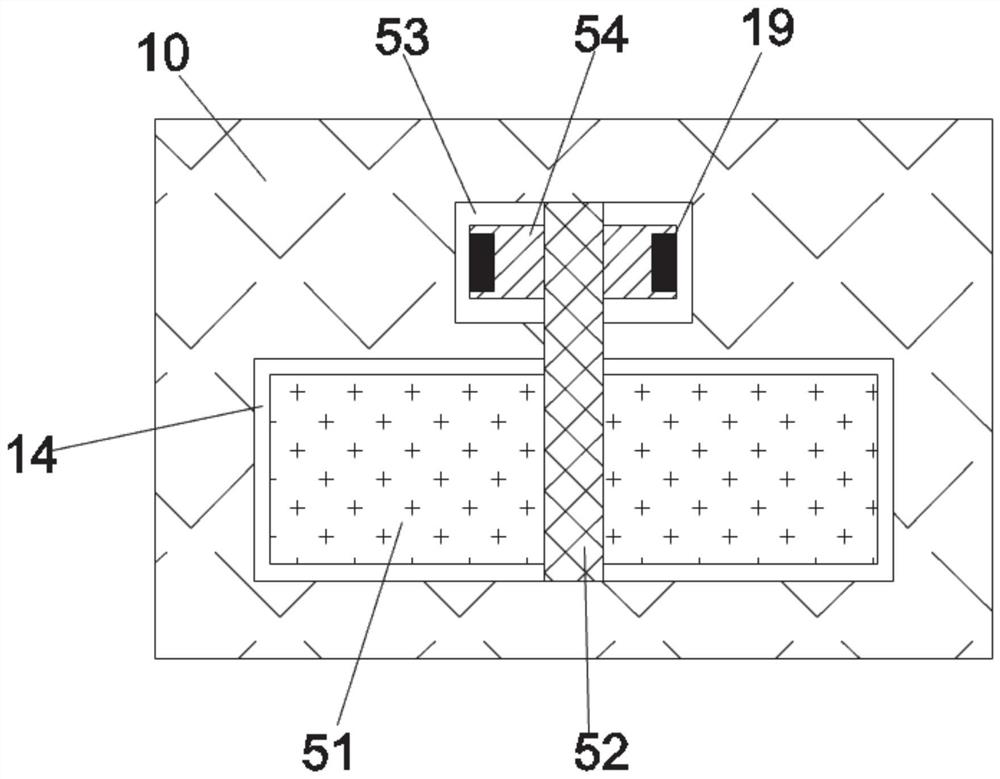

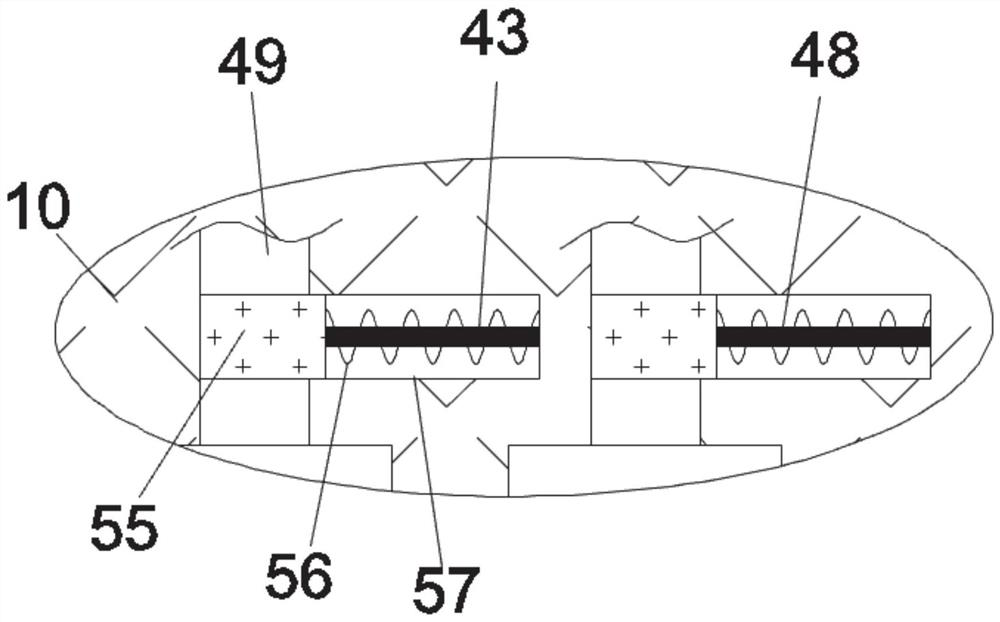

[0016] combined with Figure 1-4 The weeder for auxiliary operation includes a housing 10, an energy storage chamber 11 is arranged in the housing 10, a pendulum chamber 47 is arranged on the inner wall of the right side of the energy storage chamber 11, and the pendulum A balance detection mechanism is provided in the chamber 47, a transmission chamber 23 is provided on the inner bottom wall of the pendulum chamber 47, and two identical fluid chambers 13 are provided on the inner wall on the left side of the transmission chamber 23, between the fluid chambers 13 There is a turbine chamber 14 that cuts off the fluid chamber 13, a pneumatic mechanism is arranged in the turbine chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com