Dust-dirt separation device and dust collector

A technology for separating devices and dust. It is applied in the installation of vacuum cleaners, suction filters, and electrical equipment. It can solve the problems of easy damage and other problems, and achieve the effects of reducing occupied space, improving user experience, and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

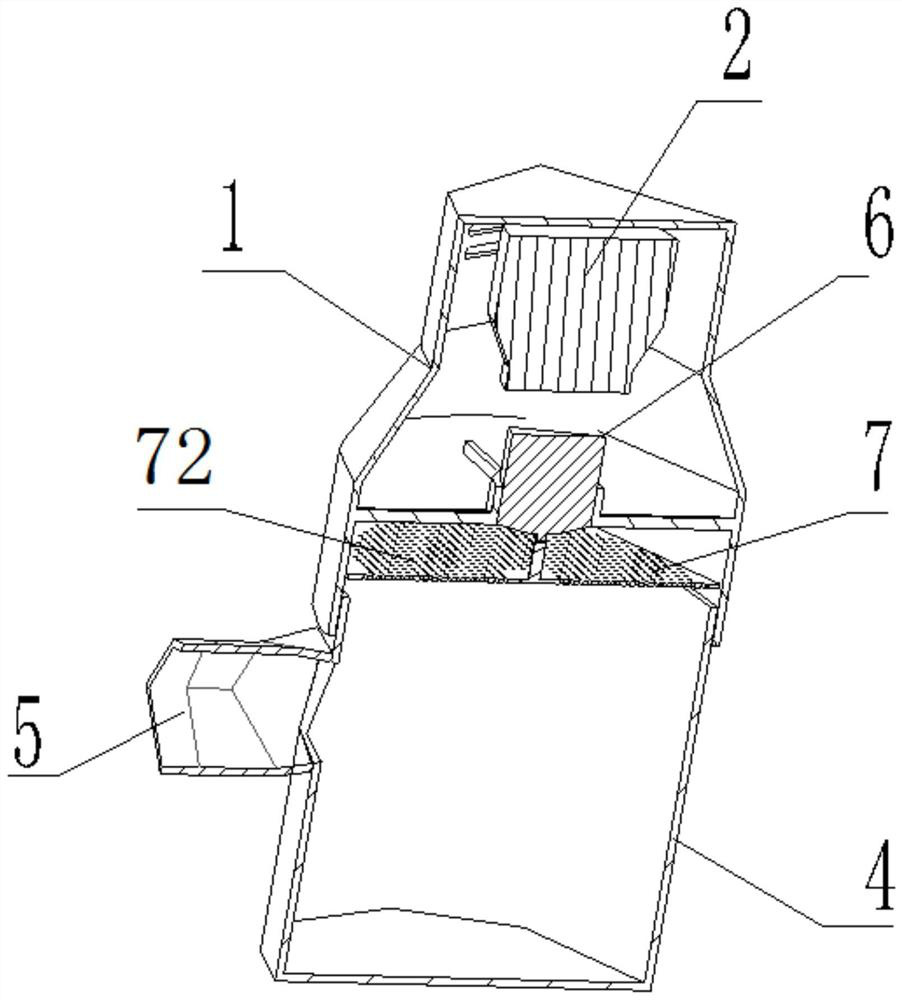

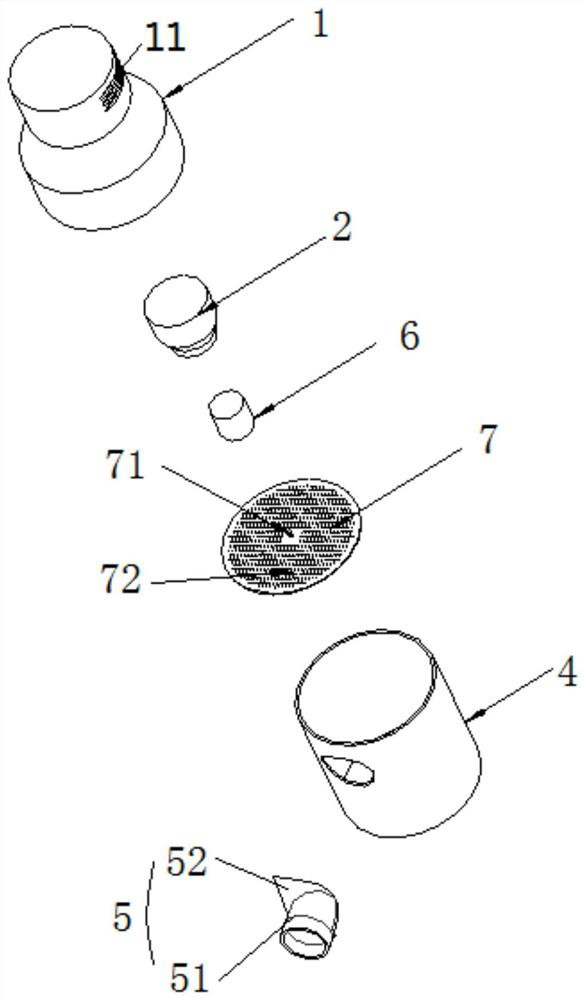

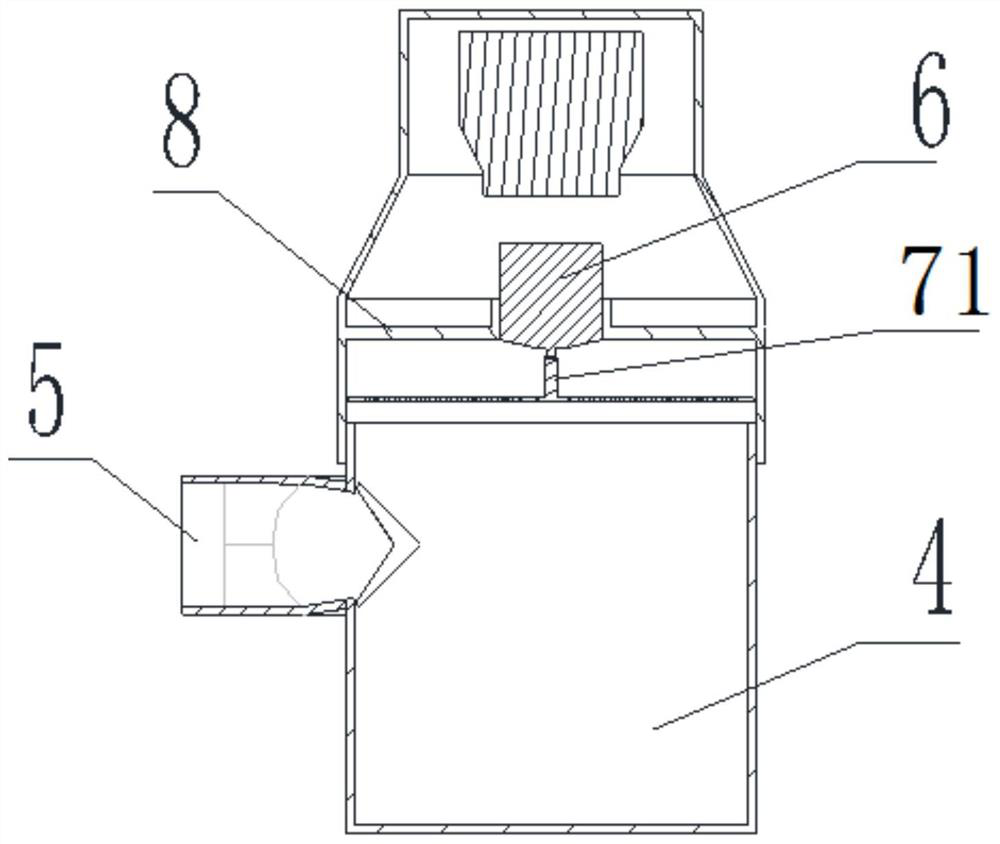

[0043] This embodiment provides a dust and dirt separation device, such as Figure 1-Figure 3 shown, including:

[0044] The main body 1 is provided with a vacuum motor 2 inside;

[0045] The wind wheel is detachably arranged on the vacuum motor 2; in this embodiment, the wind wheel is integrated inside the vacuum motor, and a through hole is provided on the housing of the vacuum motor 2, so as to realize the suction operation;

[0046] Specifically, the main body 1 itself adopts a cylindrical arrangement, the vacuum motor 2 itself is connected to an external power source, the center of the wind wheel is connected to the output shaft of the vacuum motor 2, and the output shaft is detachably connected to the center of the wind wheel. It can be connected by interference or by thread. When the wind wheel itself rotates, negative pressure will be generated in the main body 1, and the outside wind will carry dust into the dust separation device;

[0047] The dust collecting cham...

Embodiment 2

[0070] This embodiment provides a vacuum cleaner, comprising: the dust and dirt separation device provided in Embodiment 1; a dust suction pipe, one end of which is connected to the air intake part 5 of the dust and dirt separation device; a vacuum cleaner head connected to the dust suction the other end of the tube.

[0071] The vacuum cleaner head itself will be in contact with the ground, sofa, corner and other positions that need to be cleaned. When the dust separation device starts to generate negative pressure, the negative pressure will suck the dust into the dust separation device through the dust suction pipe through the vacuum cleaner head, so as to realize the storage of the dust itself.

[0072] In this embodiment, a handle can be directly provided on the dust separation device to form a hand-held vacuum cleaner. When a dust collection operation is required, the user can directly hold the handle to realize the dust collection operation.

[0073] As a modification,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com