A welding robot

A welding robot and welding wire technology, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems such as the inability to make a good judgment on the amount of welding wire, inconvenience, and welding without welding wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

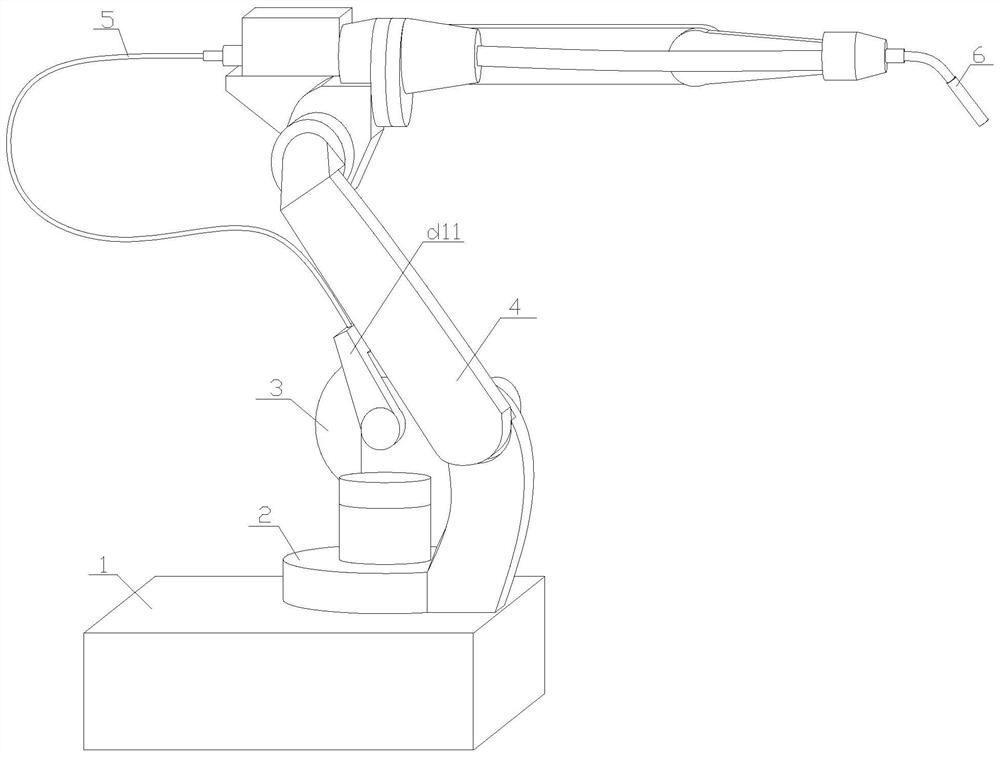

[0028] see Figure 1-Figure 7 , the present invention provides a welding robot: comprising an assembly seat 1, a rotating base 2, a welding wire assembly disc 3, a mechanical arm 4, a welding wire conveying pipe 5, and a welding torch 6, and a rotating base 2 is movably buckled on the right side of the top of the assembly base 1 , the rear end of the rotating base 2 is fixedly connected with a welding wire assembly disk 3, one end of the mechanical arm 4 is fixedly connected with the right end of the rotating base 2, the other end of the mechanical arm 4 is equipped with a welding gun 6, and the welding wire assembly disk 3 passes through the welding wire. The conveying pipe 5 is connected with the welding torch 6;

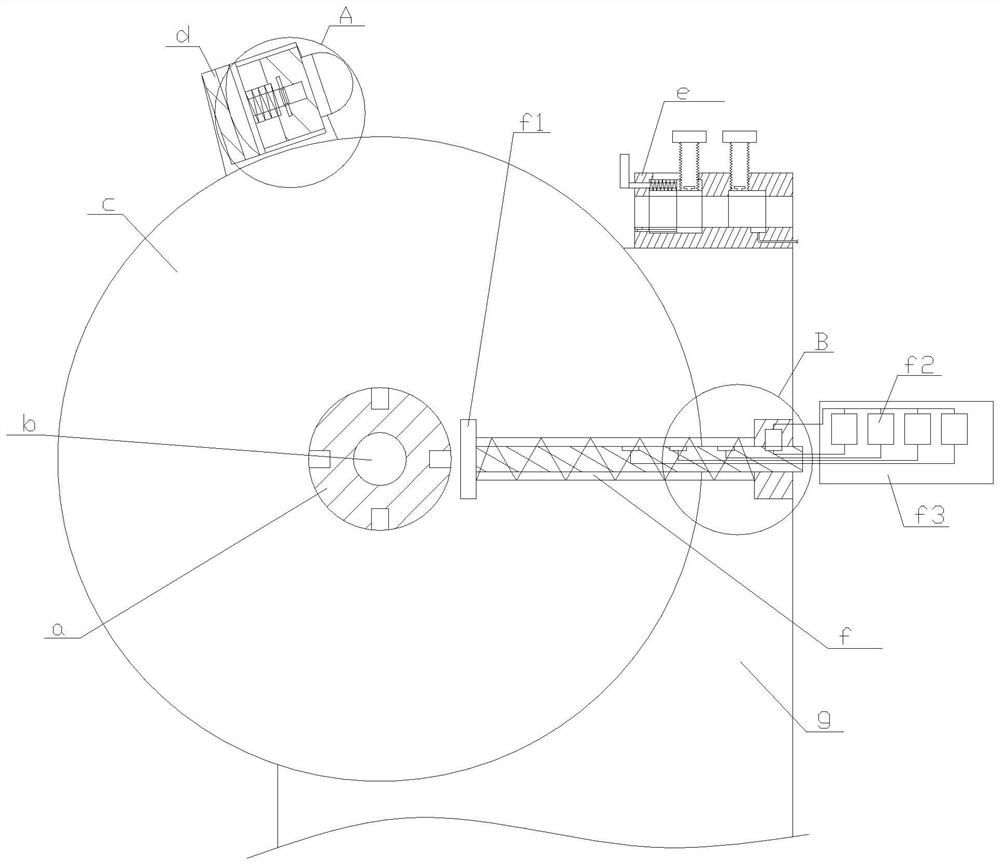

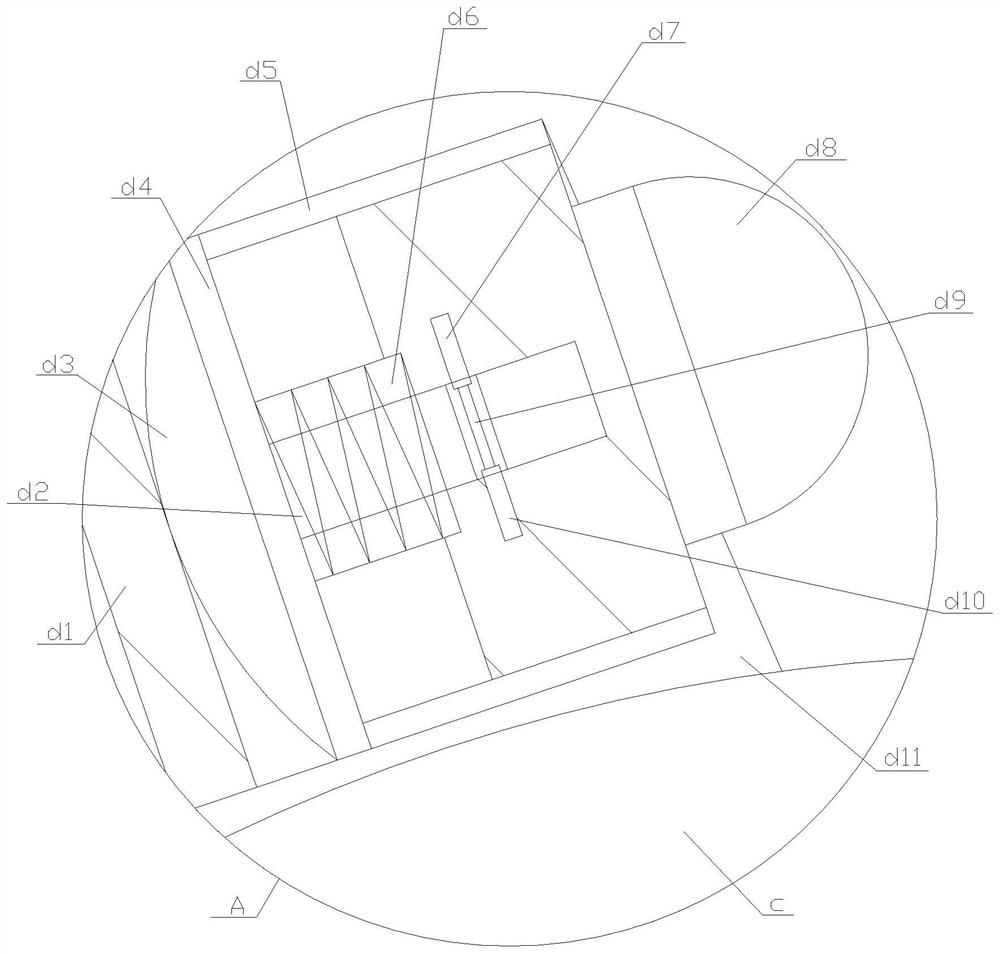

[0029]The welding wire assembling disc 3 includes a central shaft a of the disc, a movable shaft b of the disc, a side plate c of the disc, a wire feeding detection device d, a welding wire splicing device e, a margin prompting device f, and a disc assembly plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com