Polishing device with noise reduction function for machining

A mechanical processing and functional technology, applied in the direction of grinding drive device, device for fixing grinding wheel, metal processing equipment, etc., can solve the problems of low functional practicability and high noise, and achieve the effect of easy adjustment and use and guaranteeing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

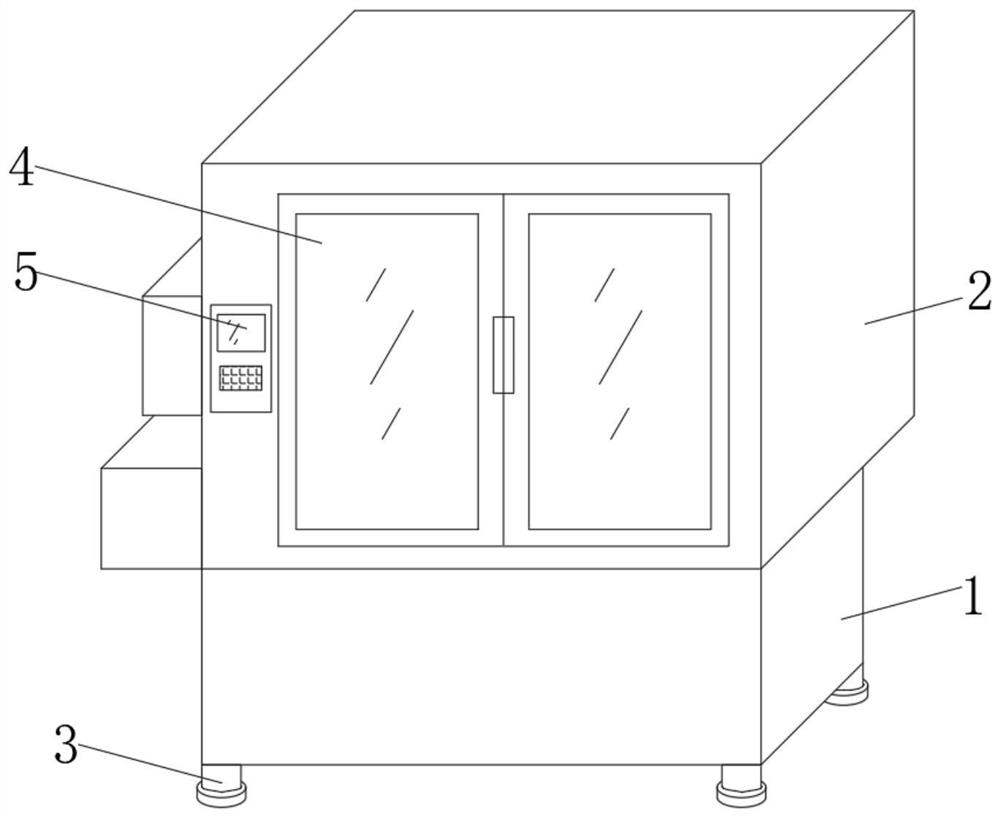

[0034] see figure 1 , a grinding device for mechanical processing with noise reduction function, comprising a stand 1, the top of the stand 1 is fixedly connected with a soundproof shell 2, the front end of the soundproof shell 2 is provided with an observation door and window 4, and one side of the observation door and window 4 is provided with control panel5.

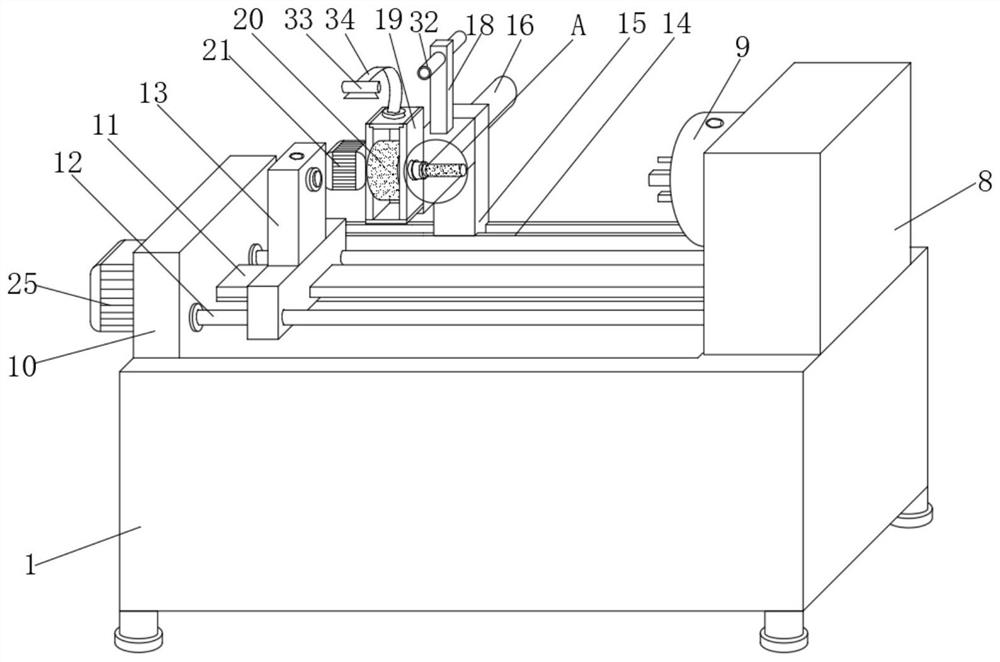

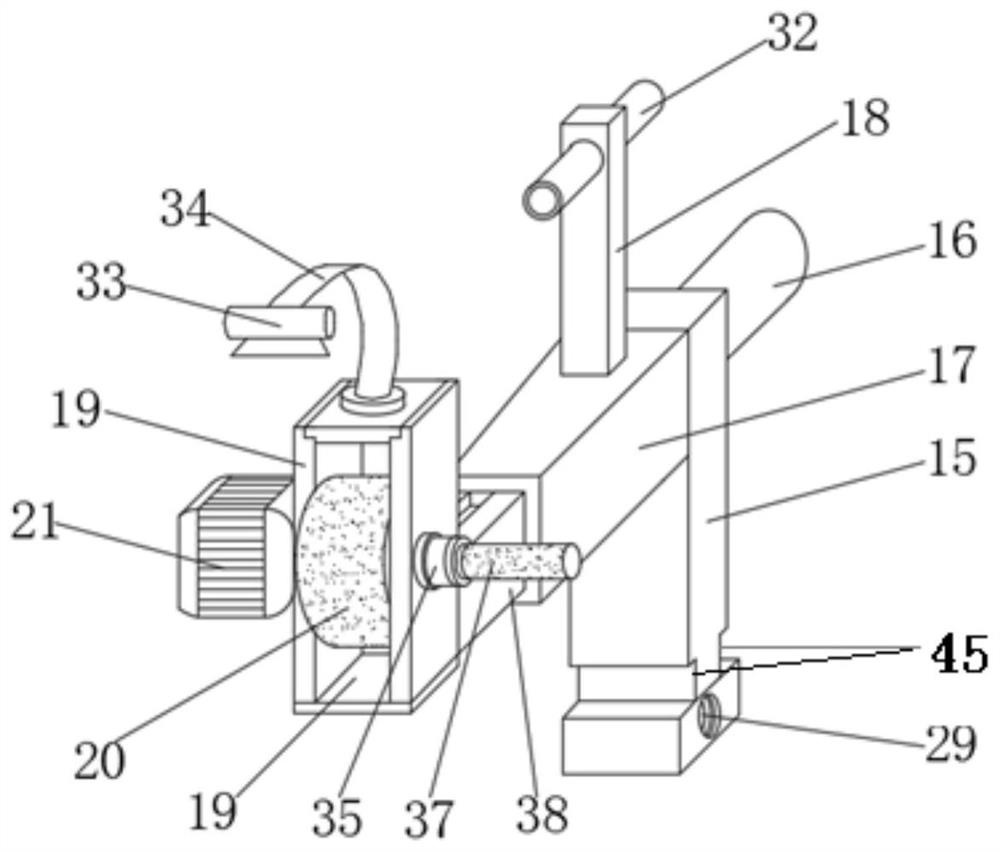

[0035] see Figure 2 to Figure 5, the soundproof shell 2 and the two sides of the top of the stand 1 are respectively provided with a transmission box 8 and a side plate 10, and a first lead screw 24 and a second lead screw 30 are respectively connected between the bottom ends of the transmission box 8 and the side plate 10. One end of the first lead screw 24 passes through the side plate 10 and is connected to the power output end of the first motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com