Lithium carbonate preparation method based on combination of salt lake ore, lithium polymer and spodumene

A lithium polymer, spodumene technology, applied in lithium carbonate;/acid carbonate, lithium halide and other directions, can solve the problems of harsh process conditions, low quality of raw materials, and low resource utilization, etc. To achieve the effect of broad process conditions, reduced production, and less potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

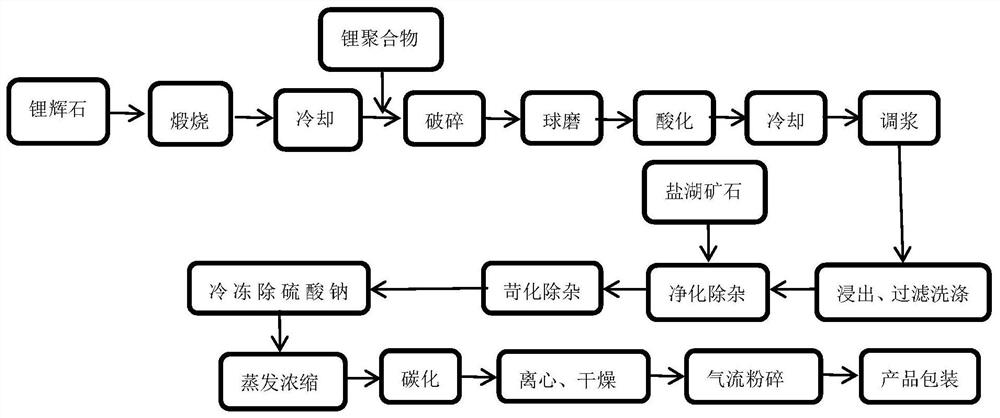

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0036] Such as figure 1 Shown, a kind of lithium carbonate preparation method based on salt lake ore, lithium polymer and spodumene combination may further comprise the steps:

[0037] S1. After the spodumene is sequentially calcined and cooled, the spodumene baking material is obtained, and the lithium polymer is added. The weight of the lithium polymer accounts for 20% to 80% of the weight of the spodumene baking material. The lithium polymer and the spodumene After the roasting material is mixed, it is crushed, finely ground, reacted with acid, and cooled. After the product to be reacted with acid is cooled to ≤90°C, it is made into a slurry with water. The solid content of the slurry is 10% to 70%, and the particle size of the finely ground is required to be 200 mesh. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com