Process for producing lithium carbonate by mixing spodumene and salt lake ore

A technology of spodumene and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve the problems of insufficient lithium ore resources, insufficient quality of products produced by salt lake ore resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The invention is further described below with reference to the accompanying drawings, but the scope of the invention is not limited to the following.

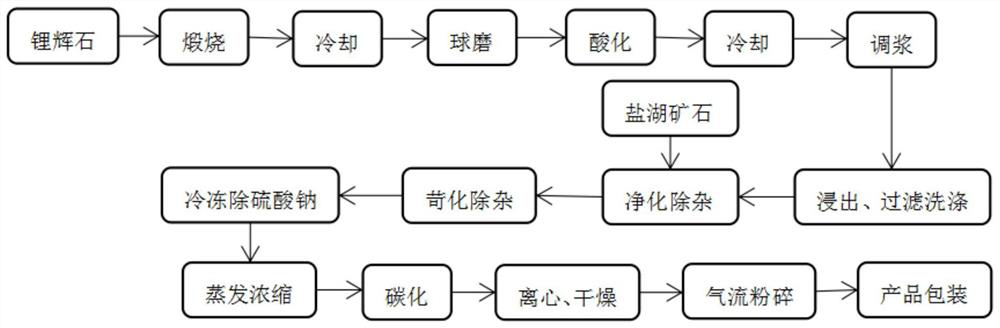

[0032]Such asfigure 1As shown, a process for mixing lithium carbonate with lithium glow and salt lake ore, including the following steps:

[0033]S1, sequentially paste the lithium, cool, fine mill, add the acid to the acid, cooled, the product to be added to ≤90 ° C, and the slurry solid content is 10% to 70%, the calcination temperature is 950 ~ 1200 ° C; the particle size of fine mill is 200 mesh; when the acid reacture is added, the concentration of 98% sulfuric acid, the acid material ratio = 2 to 4: 1, and the acid is added to 60 ° C or less;

[0034]S2, adding calcium carbonate slurry to the slurry obtained in step S1, stirring the calcium carbonate, the calcium carbonate slurry is carbonate and water, the solid content is 10% to 55%, and the temperature in the leaching tank is ≤60 ° C, pH is 5.5 ~ 6, after 20 minutes, the calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com