A kind of high-conductivity and high-strength copper-chromium-calcium alloy and preparation method thereof

A calcium alloy, high electrical conductivity technology, applied in the field of copper-chromium-calcium alloy and its preparation, can solve the problems of difficult to achieve optimal mechanical properties, decreased electrical conductivity of the alloy, large size of Cr precipitation phase, etc., to achieve process optimization, tensile strength The effect of boosting and cooling fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

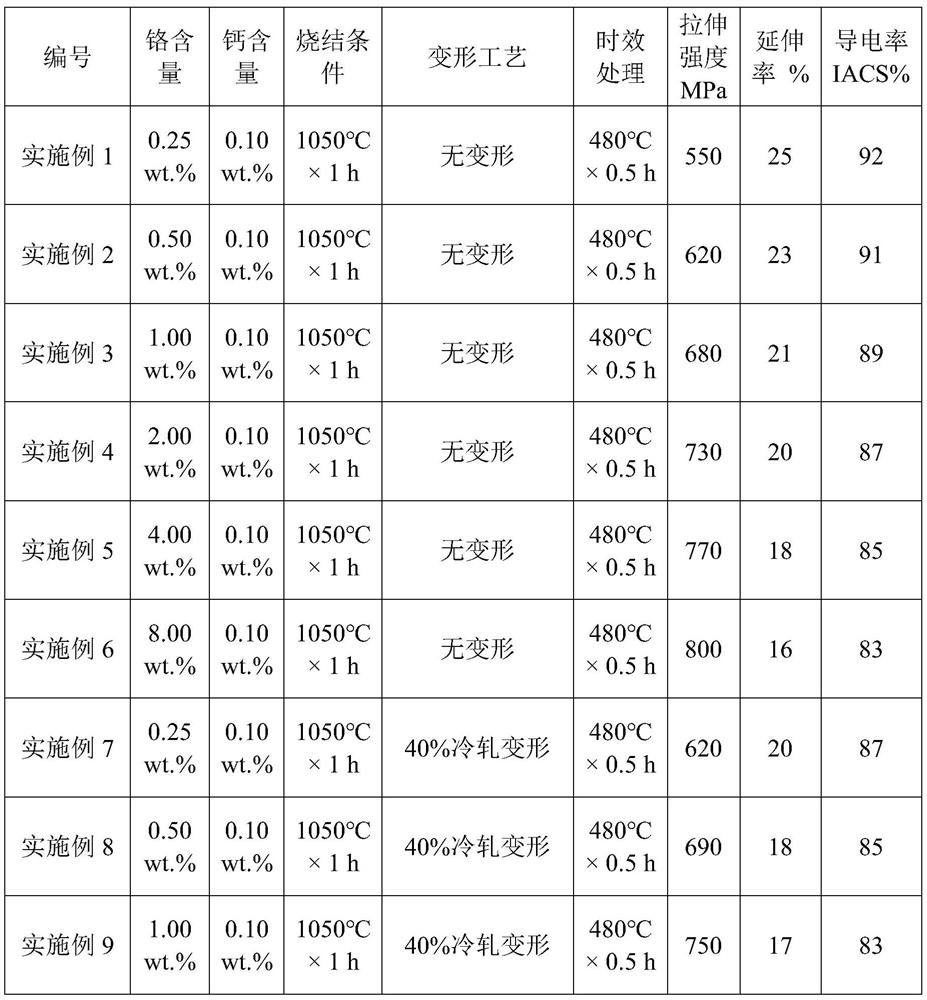

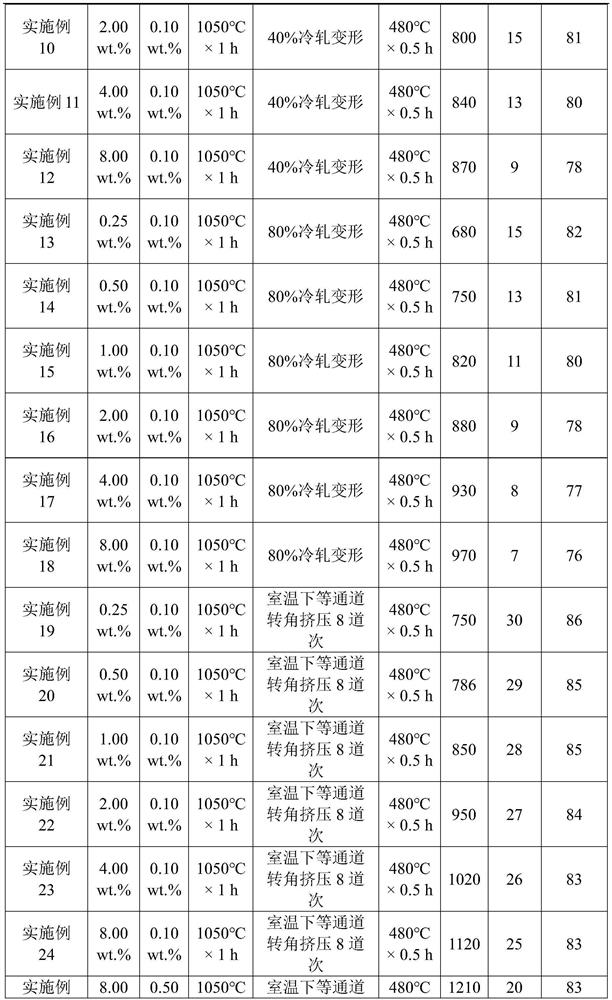

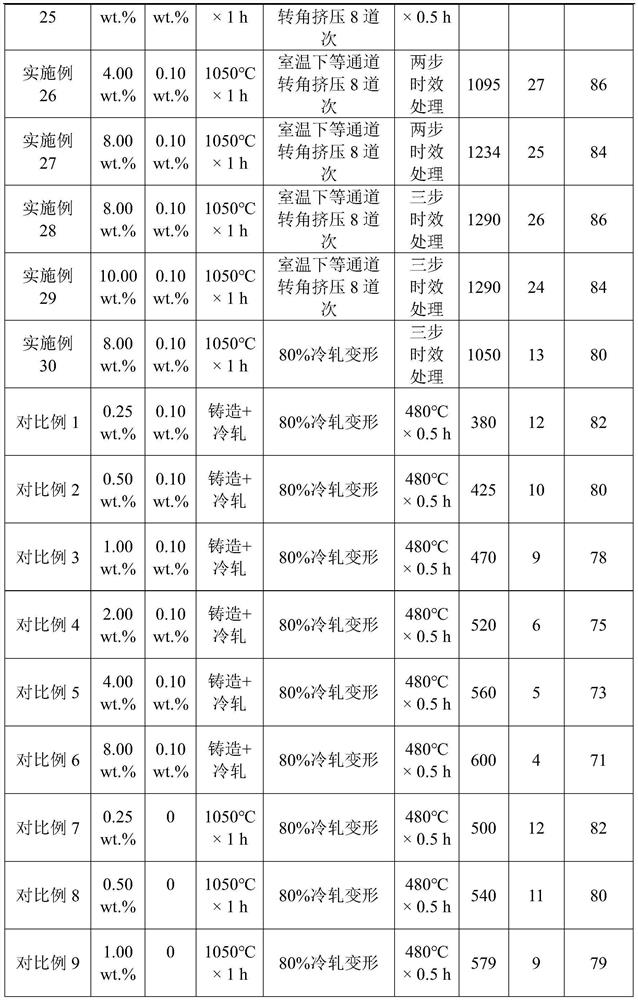

Examples

Embodiment 1

[0030] A high-conductivity high-strength copper-chromium-calcium alloy. The Cr content of the copper-chromium-calcium alloy is 0.25wt.%, the Ca content is 0.10wt.%, and the balance is copper. The electrical conductivity is 92% IACS, and the tensile strength is 550MPa. The elongation is 25%.

[0031] The preparation method of the high-conductivity high-strength Cu-Cr-Ca alloy of the present embodiment comprises the following steps:

[0032](1) According to the mass percentage of Cr / (Cu+Cr+Ca) in the alloy composition is 0.25%, the mass percentage of Ca / (Cu+Cr+Ca) is 0.10%, that is, the chromium content in the required copper-chromium-calcium alloy is 0.25wt.%, the calcium content is 0.10wt.%, and the ratio of pure copper block, copper-chromium master alloy block and copper-calcium master alloy block; under nitrogen atmosphere, the alloy powder is prepared by gas atomization method, and the pressure of the gas atomization process The melting temperature is 0.5-0.7MPa, and the m...

Embodiment 2

[0034] A high-conductivity and high-strength copper-chromium-calcium alloy. The Cr content of the copper-chromium-calcium alloy is 0.50wt.%, the Ca content is 0.10wt.%, and the balance is copper. The electrical conductivity is 91% IACS, and the tensile strength is 620MPa. The elongation was 23%.

[0035] The preparation method of the high-conductivity and high-strength Cu—Cr—Ca alloy of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0037] A high-conductivity and high-strength copper-chromium-calcium alloy. The Cr content of the copper-chromium-calcium alloy is 1.00wt.%, the Ca content is 0.10wt.%, and the balance is copper. The electrical conductivity is 89% IACS, and the tensile strength is 680MPa. The elongation was 21%.

[0038] The preparation method of the high-conductivity and high-strength Cu—Cr—Ca alloy of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com