Method for engineering absorption application of ardealite raw slag

A phosphogypsum and engineering technology, applied in the field of safe and standardized storage of phosphogypsum, can solve problems such as dam cracks, dissatisfaction, settlement deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

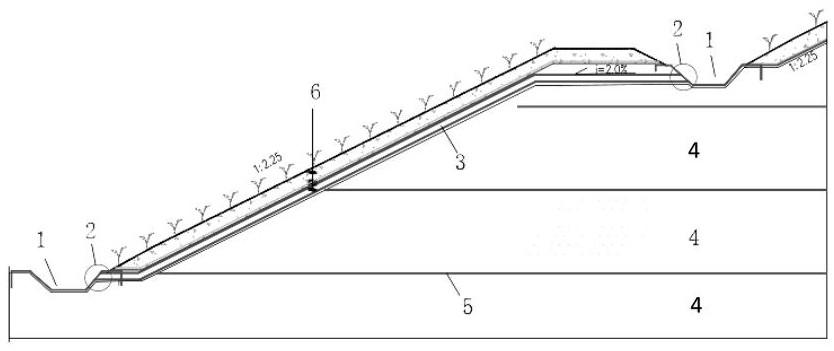

[0020] A method for phosphogypsum raw slag engineering consumption and application, the steps are as follows:

[0021] (1) Surface cleaning of the site: Care should be taken not to leave vegetation, tree roots, etc. during the surface cleaning process.

[0022] (2) Phosphogypsum filling: Use excavator to load, 15t dump truck to transport to the backfilling work surface for unloading, use loader to spread the filling, and then sprinkle water, rotary tillage, and use road roller for layered compaction; sprinklers must Grasp the watering amount of dam materials in each area. When it rains, the amount of rainfall can be determined by the laboratory. After the rolling is completed, samples will be taken on site according to the design requirements. After the test meets the design requirements, the next process can be carried out.

[0023] (3) Three-way geogrid laying: The construction site is required to be compacted and level, and sharp protrusions should be removed; on a flat and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com