Gas field water tank blowout preventer and preparation method thereof

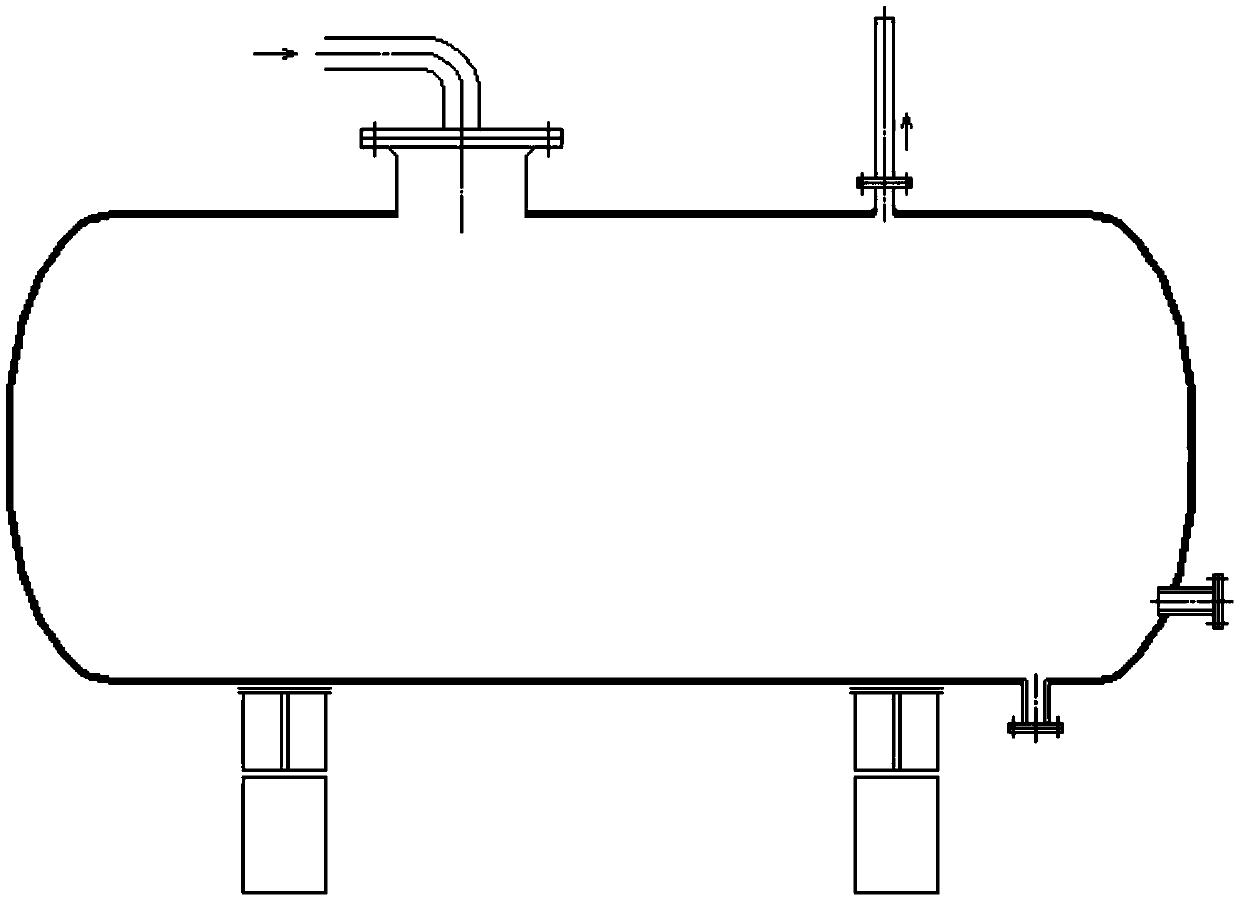

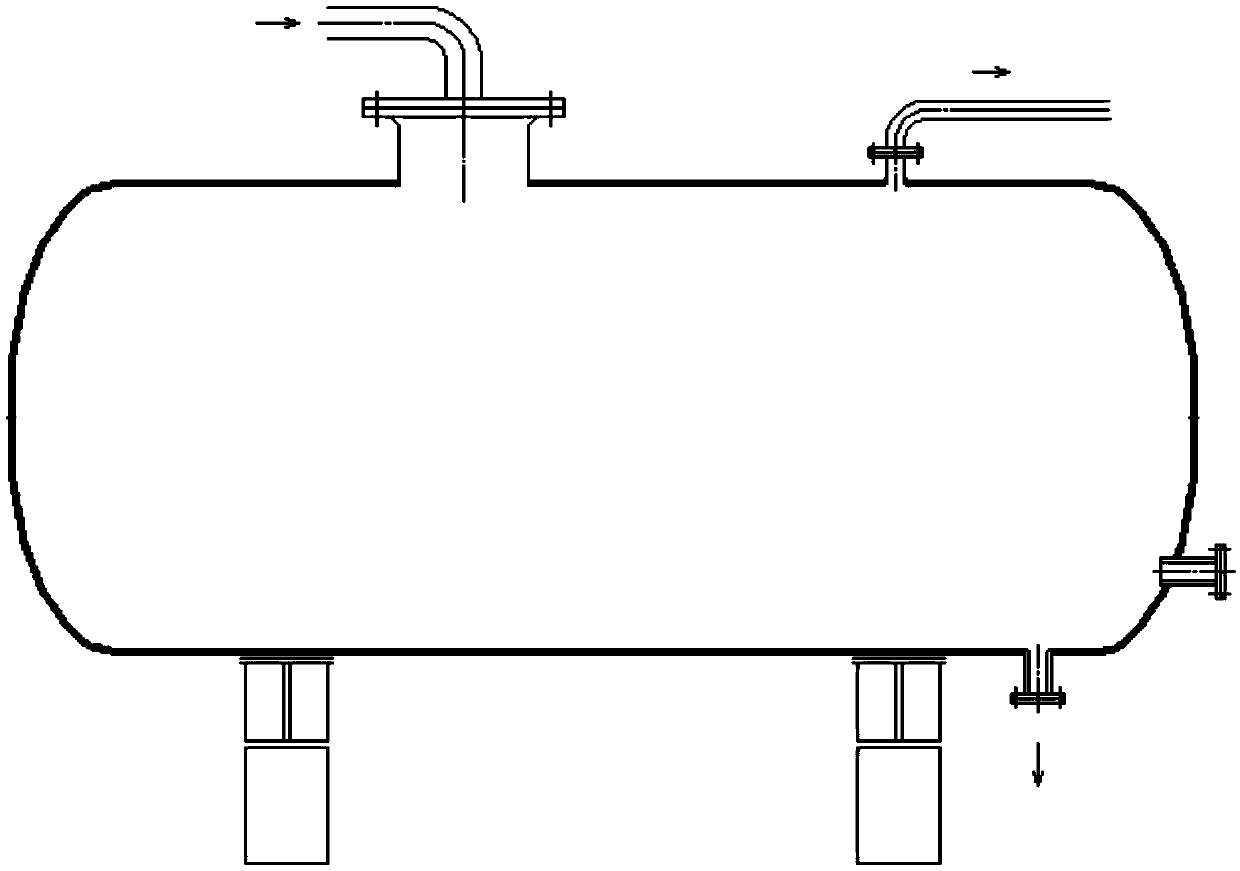

A gas field water tank and blowout preventer technology, which is applied to containers, large containers, packaging, etc., can solve the problems of low installation of flash steam pipelines, hidden safety hazards, and harm to stations, so as to reduce the number of maintenance and repairs, improve the water output speed, The effect of reducing flow energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the description of the drawings and the embodiments. The manner of the present invention includes but is not limited to the following embodiments.

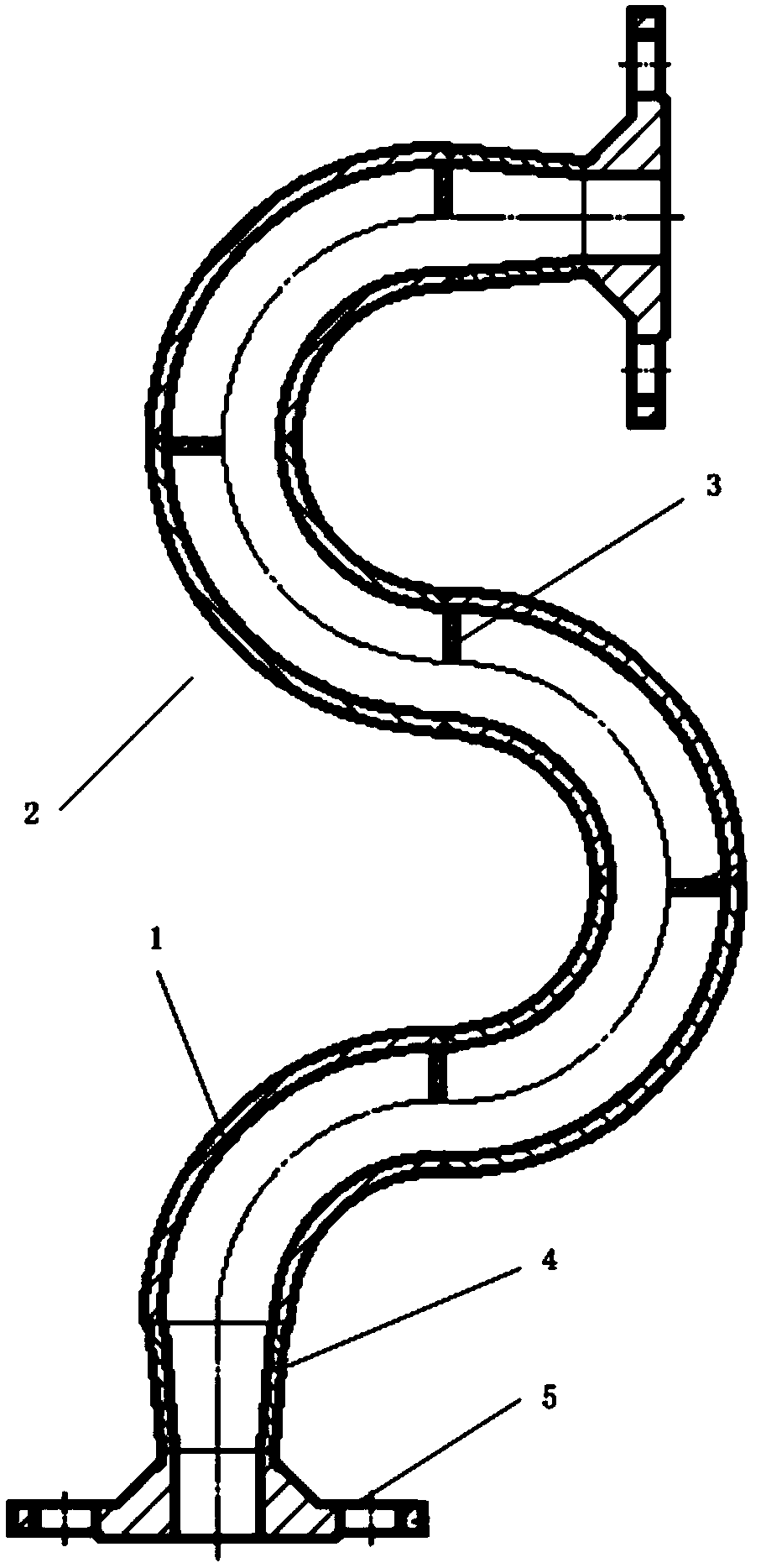

[0037] Such as Figure 3~5 Shown: A blowout preventer for gas field water tanks, including a blowout preventer body 2 welded to each other by a plurality of elbows 1, and a baffle welded in the blowout preventer body 2 for water flow impact pressure reduction 3. The small and small heads 4 welded to the two ends of the blowout preventer body 2 and used for reducing pressure, and the flanges 5 welded to the ends of the small head 4 for external equipment.

[0038] Preferably, the elbow 1 adopts a 90-degree elbow, and a plurality of the elbows 1 are located in the same plane and are welded to form an "S-shaped" blowout preventer body 2. According to the impact of the gas field water tank inlet Size, select the number of elbows, increase the number of bends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com