Sampling device for road engineering detection and sampling method thereof

A sampling device and road engineering technology, applied in the direction of sampling devices, etc., can solve the problems of not being able to detect the usage of cooling water in real time, sample removal by the sampling machine, and low work efficiency, so as to increase the stability effect, reduce the temperature, and reduce the The effect of labor output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

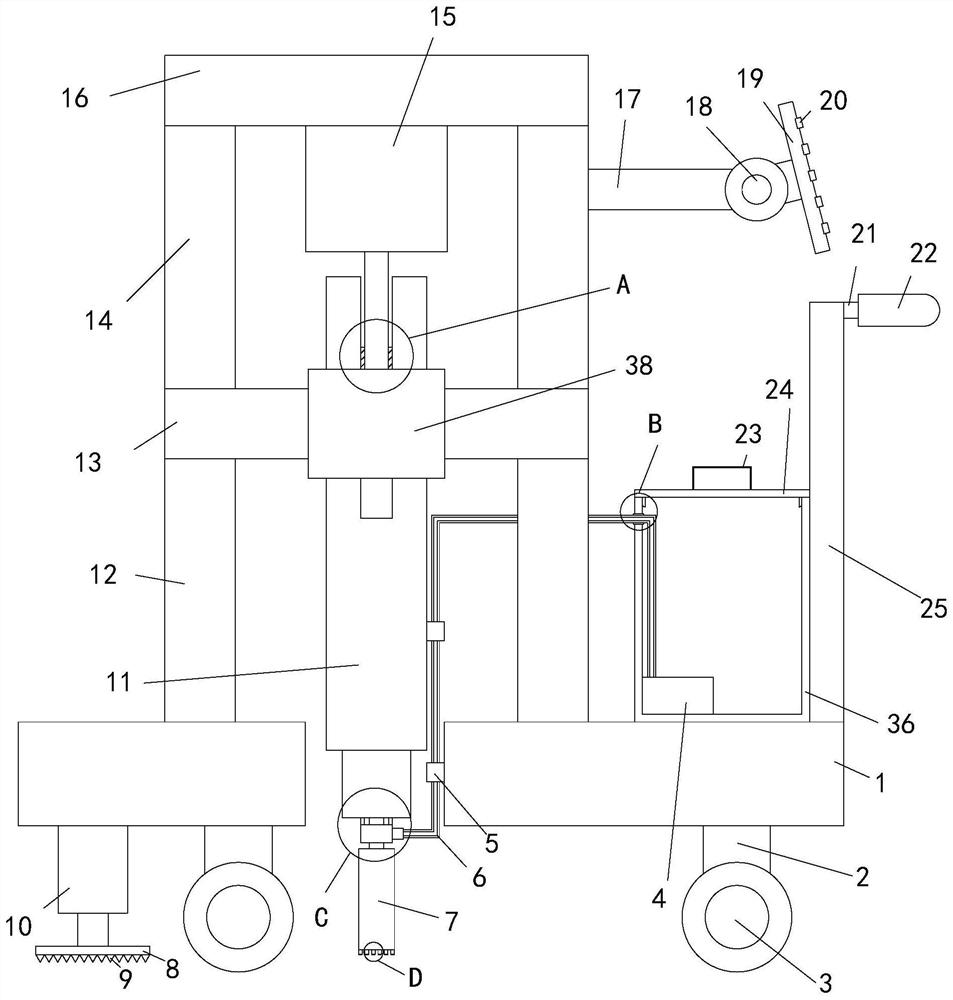

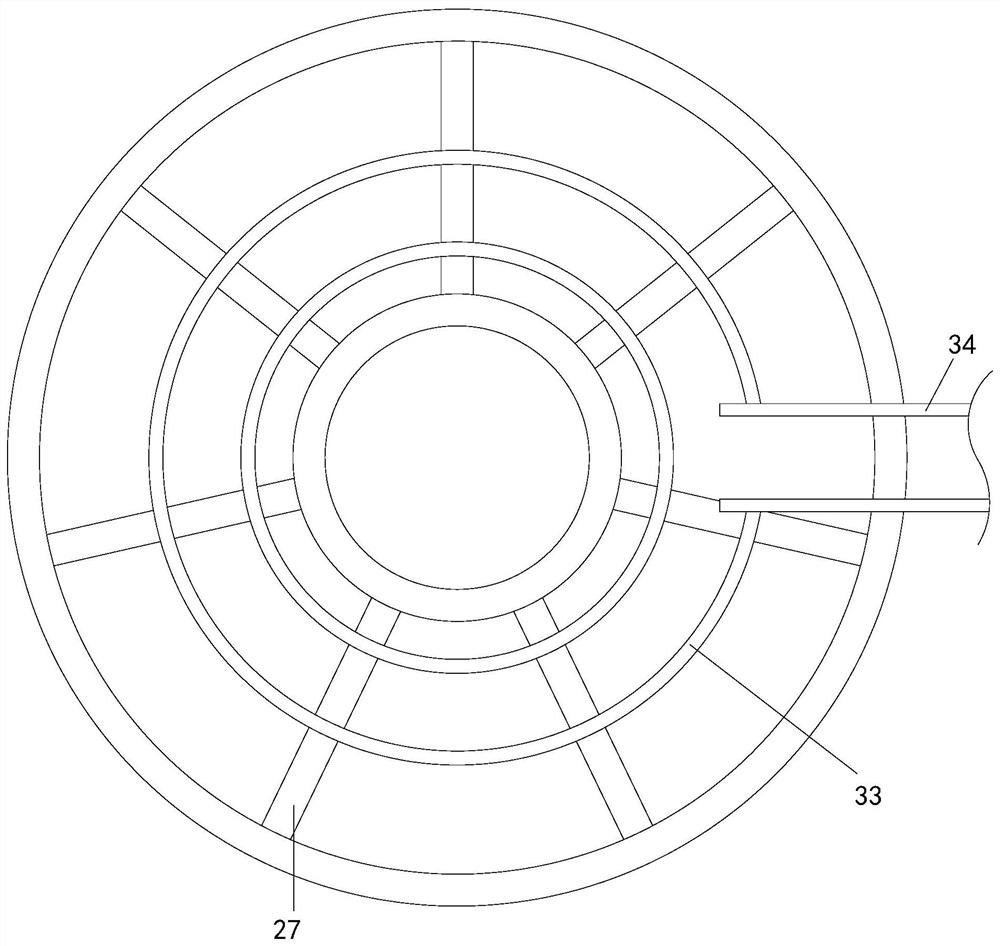

[0033] see Figure 1-7, a sampling device for road engineering detection, comprising a base plate 1, the top of the base plate 1 is provided with a cooling box 36, and the inner bottom wall of the cooling box 36 is provided with a water pump 4, the output end of the water pump 4 is communicated with a water pipe 6, and the water pipe 6 One end passes through the cooling box 36 and extends to the outside of the cooling box 36. The bottom of the cooling box 36 is provided with a water level sensor. The top of the bottom plate 1 is symmetrically provided with a lower strut 12, and the top of the lower strut 12 is connected with a connecting plate 13. The top of connecting plate 13 is provided with upper strut 14 symmetrically, and the top of upper strut 14 is connected with top plate 16, and the bottom end of top plate 16 is provided with motor one 15, and the output end of motor one 15 is provided with connecting rod 29, and connects The lower area of the outer peripheral wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com