Method for designing optimal PID parameters of closed-loop control system of nuclear power plant

A closed-loop control and design method technology, applied in general control systems, control/regulation systems, electric controllers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

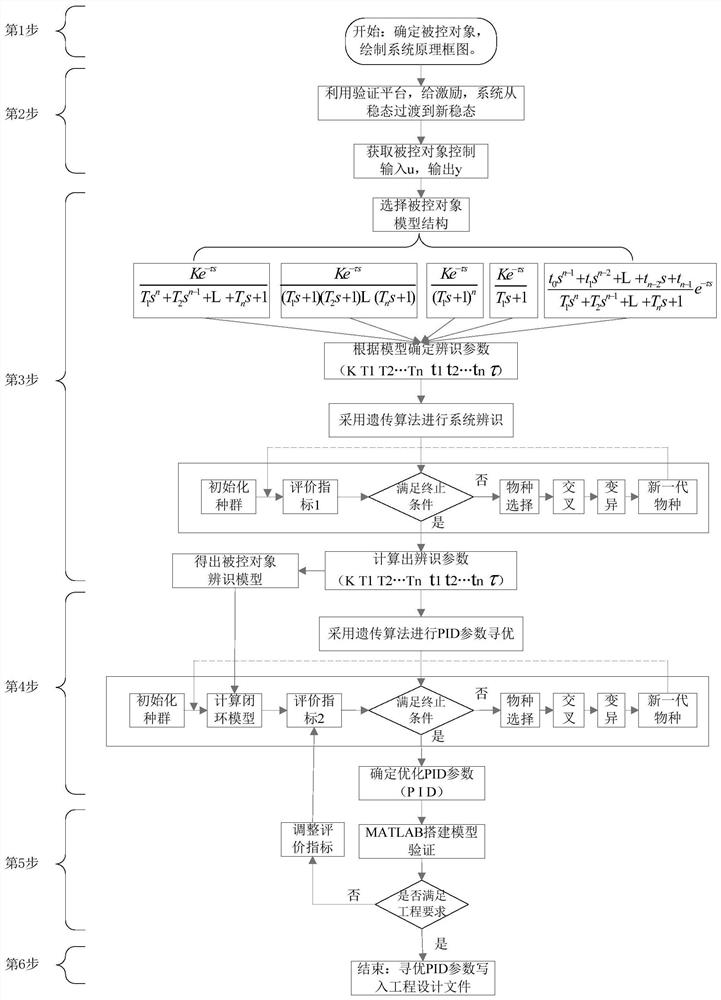

[0064] Such as figure 1 As shown, a kind of design method of optimal PID parameter of nuclear power plant closed-loop control system provided by the present invention is used to obtain the optimal PID parameter of the closed-loop control system that meets engineering index requirements, comprising the following steps:

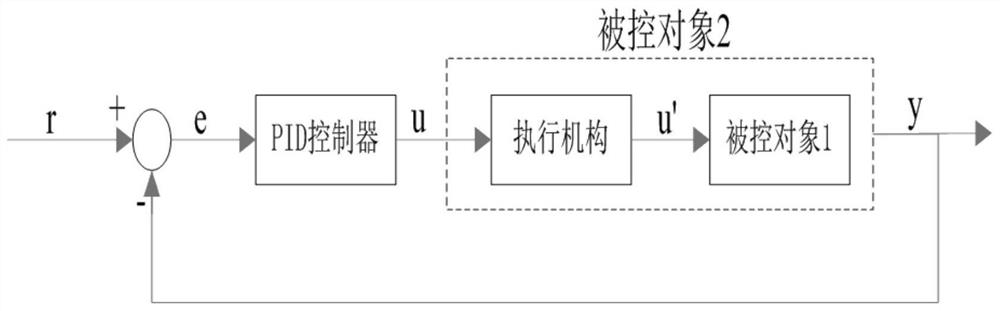

[0065] Step S1, determine the closed-loop control system that needs to optimize the PID parameters, draw the closed-loop control system block diagram of the closed-loop control system (ie, the system principle block diagram), and determine the controlled object;

[0066] Step S2, carry out nuclear power plant simulation on the nuclear power plant design verification platform, and run the closed-loop control system;

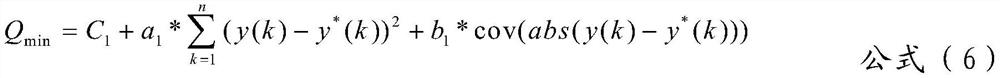

[0067] Step S3, determining the model structure and model parameters of the controlled object, using the genetic algorith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com