Method for establishing pyrolytic carbon PyC interface model of ceramic-based composite material and predicting shear strength

A composite material and interface model technology, applied in the fields of instrumentation, electrical digital data processing, computer-aided design, etc., can solve the problem of inability to accurately calculate the interface shear strength of ceramic matrix composites pyrolytic carbon PyC, etc., to avoid the requirements of testing equipment High, avoid sample preparation difficulties, predict the effect of accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In this example, the PyC interface shear strength of the SiC / PyC / SiC composite material at room temperature was predicted.

[0067] A method for predicting the PyC interface strength of ceramic matrix composite material pyrolytic carbon, specifically comprising the following steps:

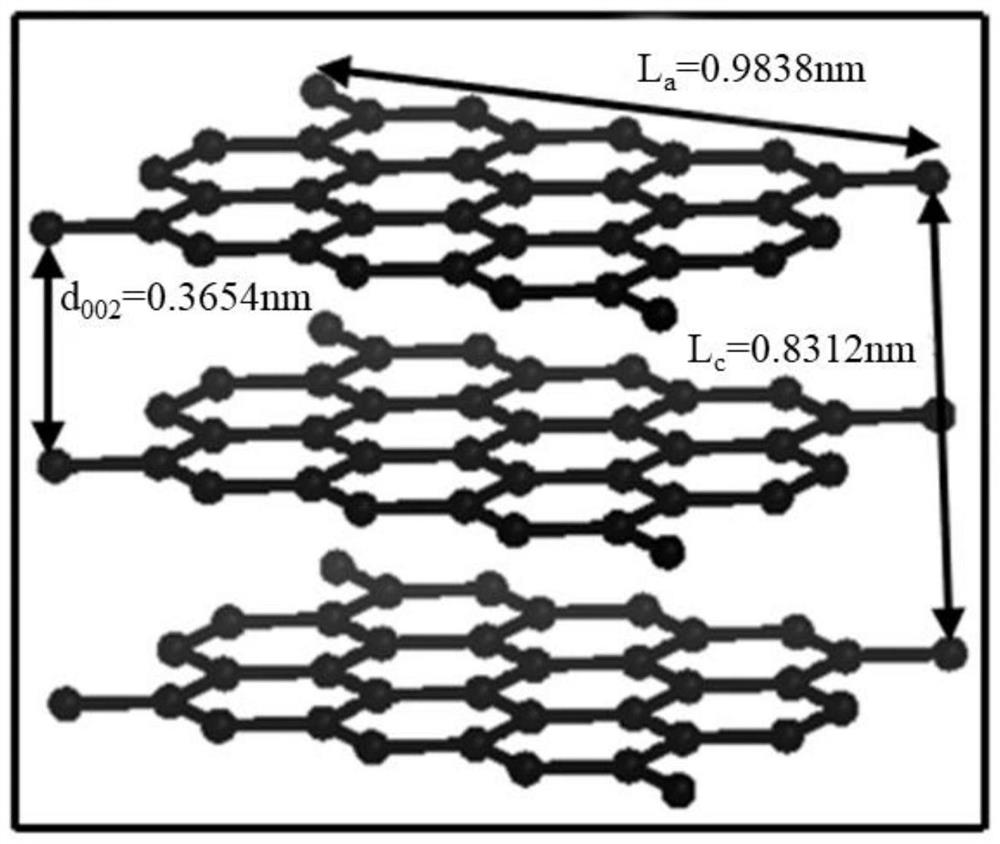

[0068] Step (1), establishing the PyC interface turbostratic graphite layer unit model: According to the observation results of the microstructure of the PyC interface layer, the carbon layer spacing, the stacking height of the carbon layer, the size of the carbon layer and the order degree of the carbon layer are calculated. Structural parameters establish ordered graphite-like layer units.

[0069] Step (1) specifically includes the following steps:

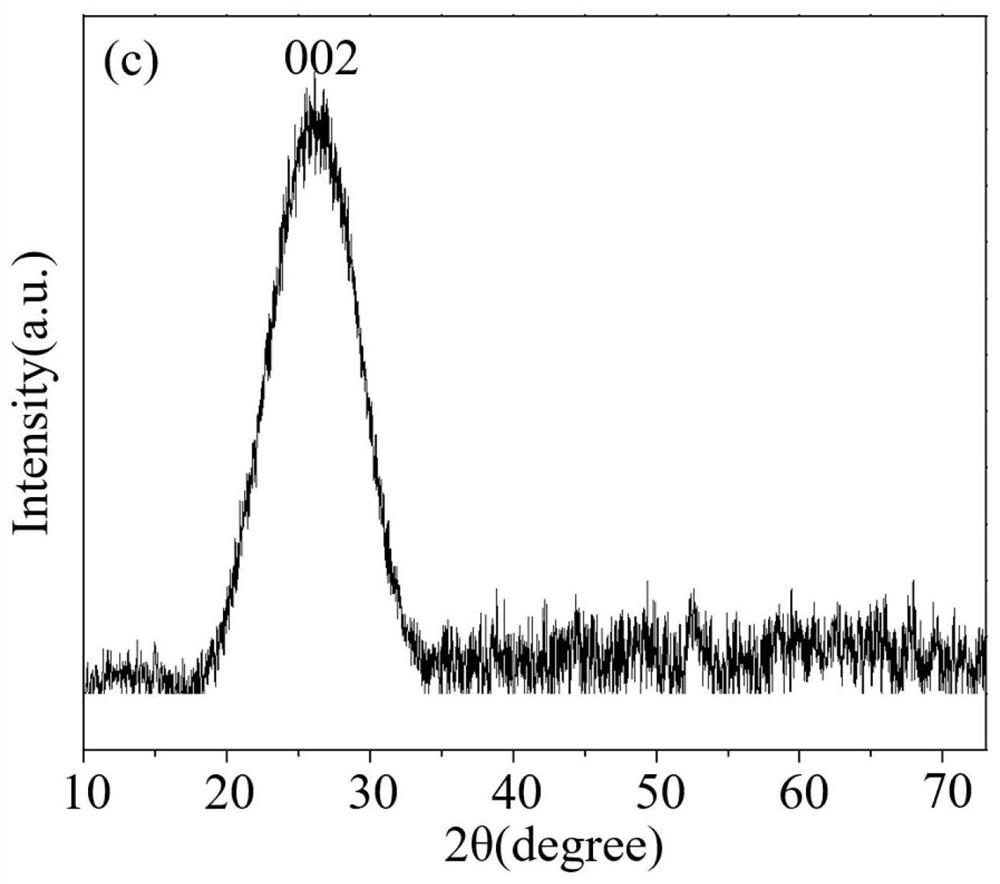

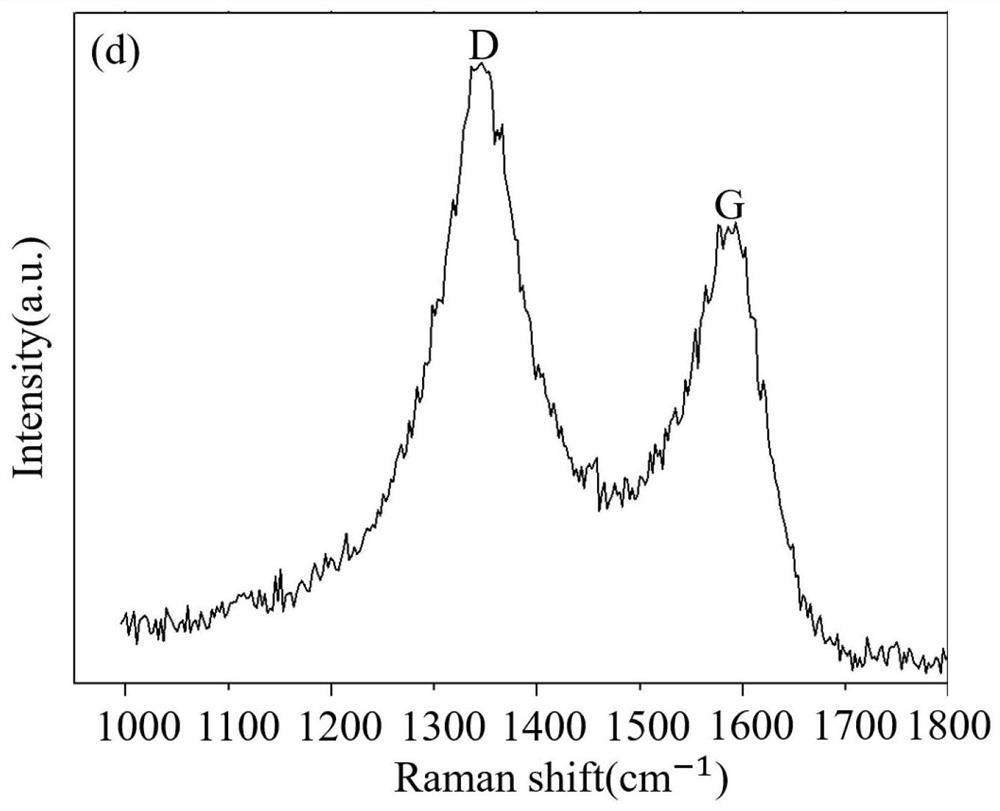

[0070] Using micro-area XRD and Raman spectroscopy to observe the PyC interface microstructure of SiC / PyC / SiC composites at room temperature, figure 1 is the XRD spectrum of the PyC interface of the SiC / PyC / SiC composite material at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com