Small food tank bottom weld joint grinding machine

A technology for grinding machines and tanks, which is applied to the parts of grinding machine tools, grinding workpiece supports, grinding/polishing equipment, etc., which can solve the problem of dependence, grinding efficiency not meeting the actual needs of production, and uncontrollable grinding quality And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

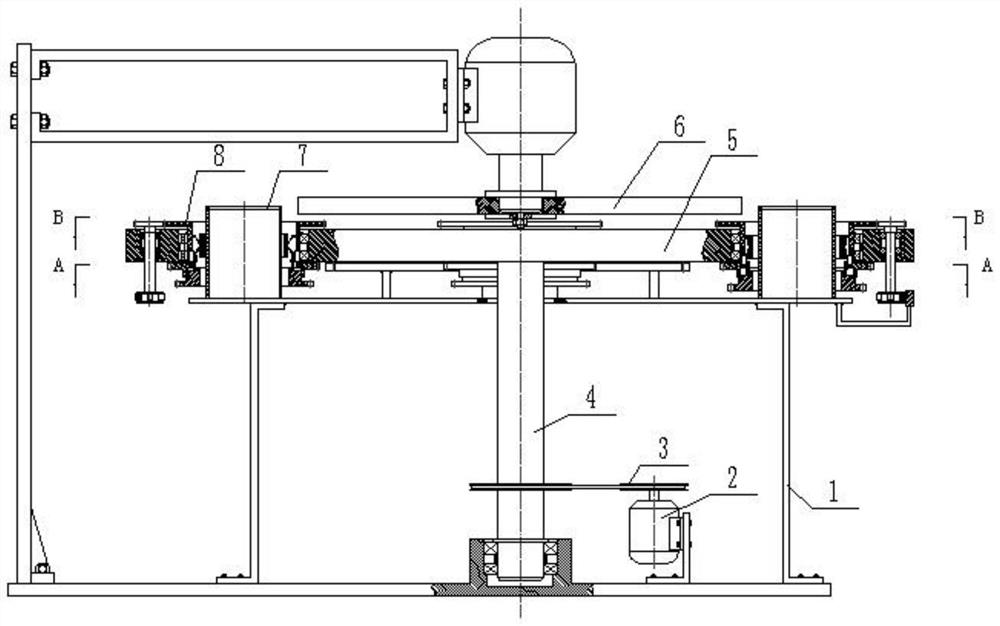

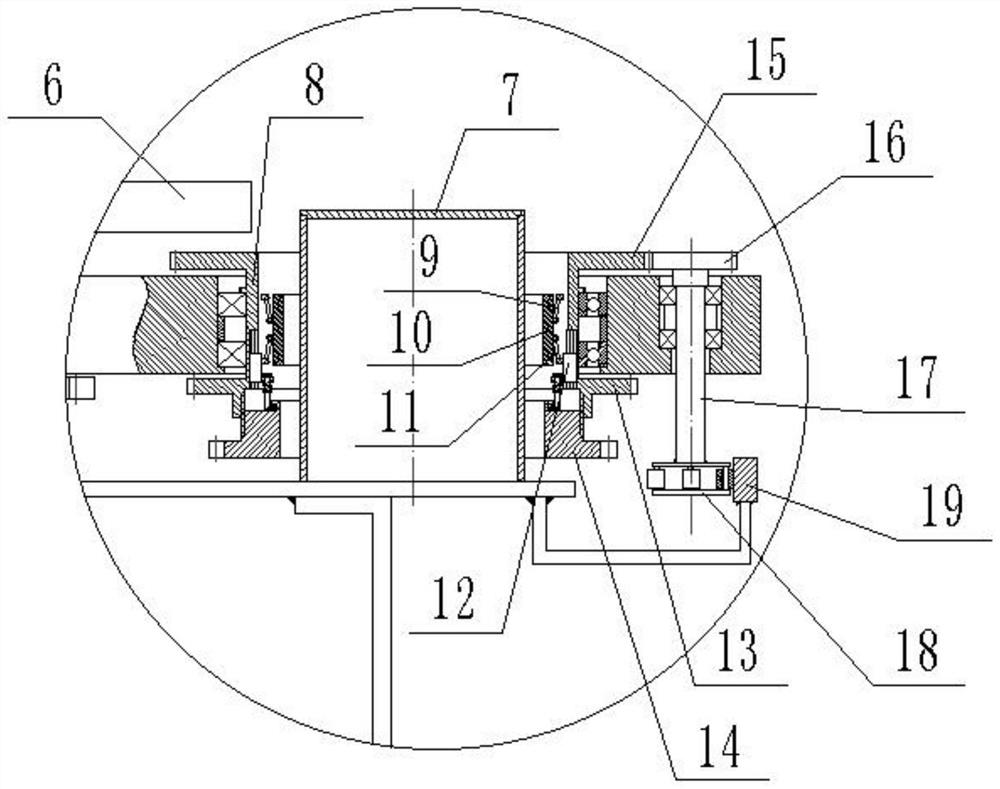

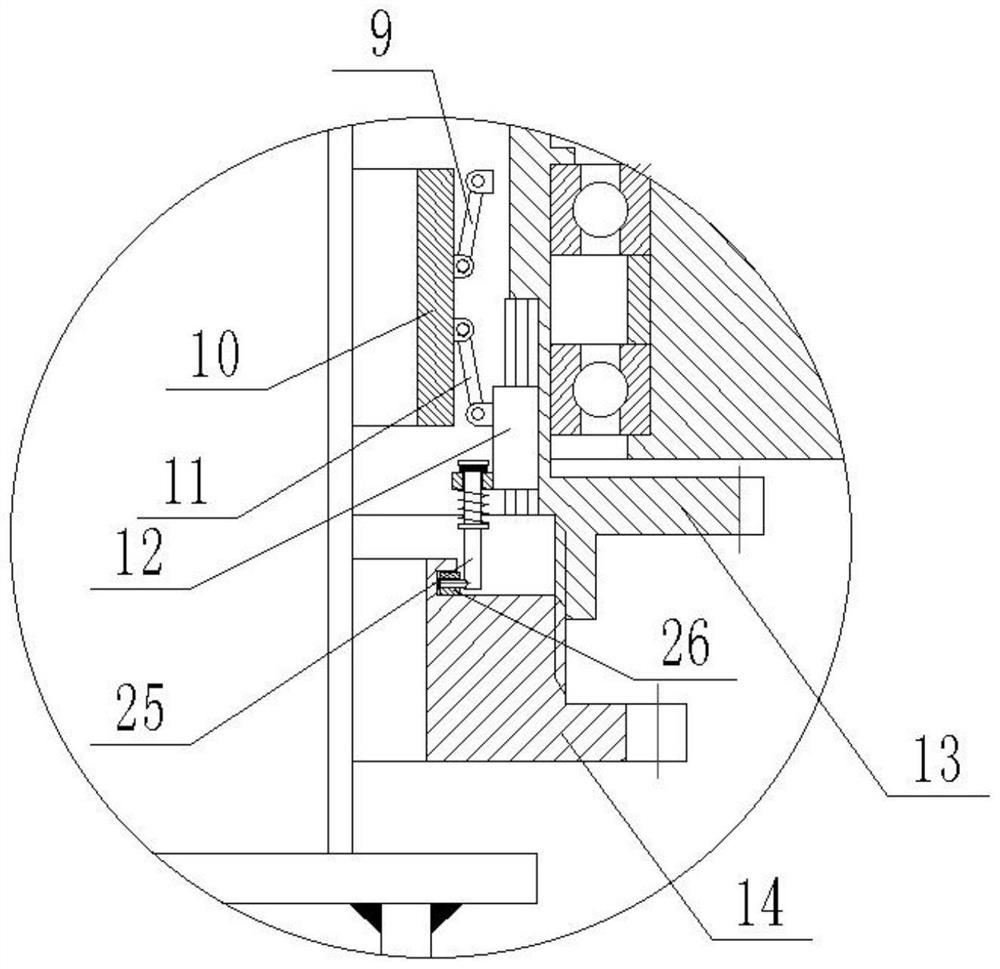

[0040] Such as Figures 1 to 8 As shown, a small-sized tank bottom weld seam grinder for food includes a rotating disc 5 support 1, a rotatable rotating disc 5 is arranged on the rotating disc 5 bracket 1, and the rotating disc 5 is connected with a main rotating shaft 4. Belt pulley pair 3 and main drive motor 2 are connected on the rotating shaft 4, and main driving motor 2 preferably uses servo motor, and main driving motor 2 drives main rotating shaft 4 and rotating disk 5 to rotate by belt pulley pair 3, and rotating disk 5 is provided with a can Rotating clamping station, the rotatable clamping station is a certain distance away from the rotation center of the rotating disk, and the tank body 7 to be ground is arranged on the rotatable clamping station;

[0041]A rotatable grinding wheel disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com