Sleeper prestress single-end tensioning machine head

A prestressing and tensioning technology, applied in ceramic molding machines, auxiliary molding equipment, instruments, etc., can solve the problems of prestressed structural deformation, prestressed structural cracks, inconvenient use, etc., achieving a high degree of mechanization and improving processing quality. , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate those skilled in the art to understand the technical solution of this patent, the technical solution of this patent will be further described in the form of specific cases below.

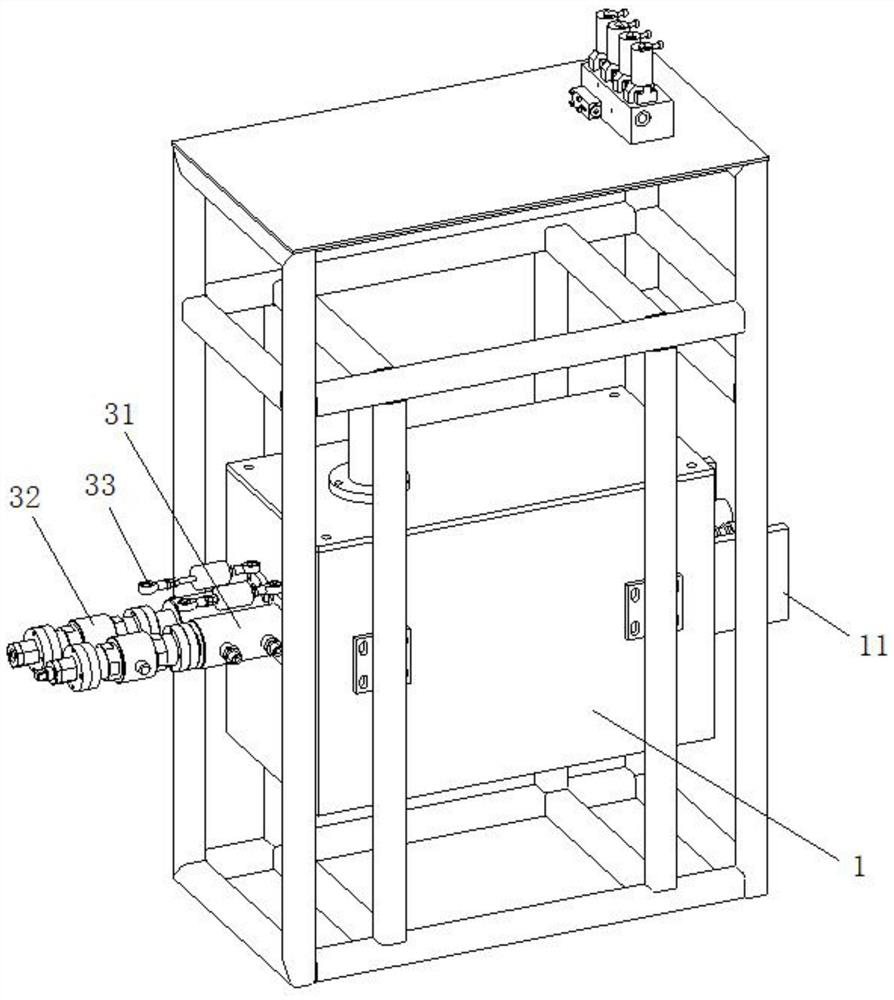

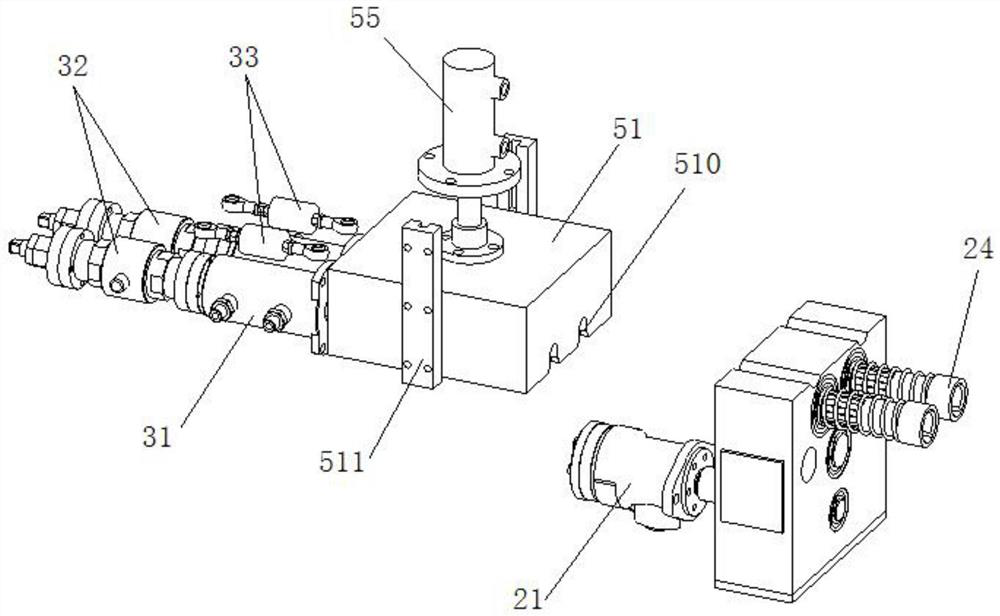

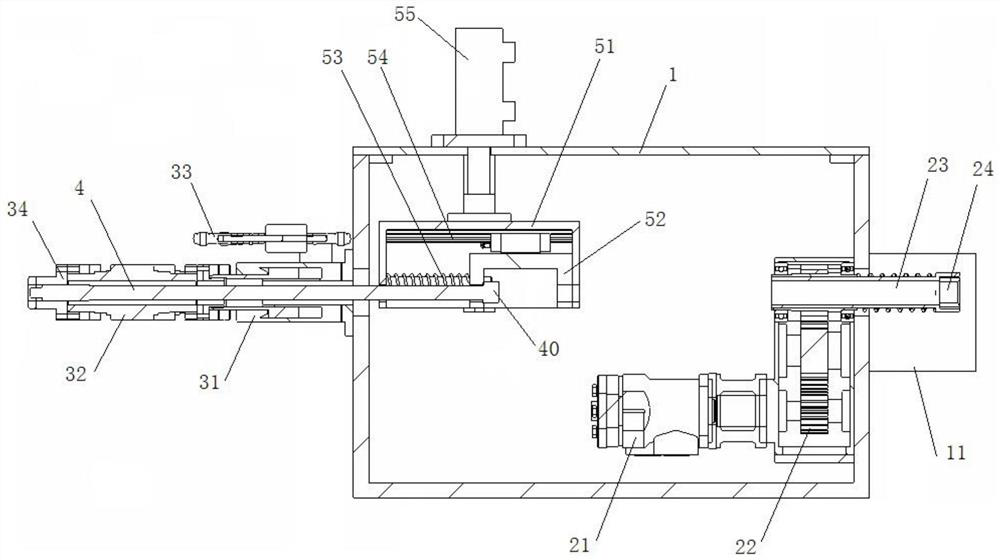

[0034] Such as Figure 1~5 As shown, a sleeper prestressed single-end tensioning head includes a housing 1 for transmitting pressure. The front end of the housing 1 is provided with a top arm 11, and the rear end of the housing 1 is provided with two side-by-side through-type jacks. 31. Each through-type jack 31 is provided with a force sensor 32 and a displacement sensor 33, and each through-type jack 31 is equipped with a main tie rod 4, and the front part of the housing 1 is also provided with two motors 21 driven Nut screwing mechanism, the screwing head 24 of the nut screwing mechanism is exposed at the front end of the housing 1, and the screwing head 24 is a through straight path to the rear end of the nut screwing mechanism, and each straight path faces a main t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com