Intelligent monitoring and detecting system integrating multiple sensors and used for multi-shaft additional material manufacturing

A multi-sensor and additive manufacturing technology, which is applied in the direction of program control, processing and manufacturing, and additive manufacturing in sequence/logic controllers, can solve the problem of process mechanism characterization and the application of additive manufacturing equipment, which is difficult to achieve manufacturing efficiency and guarantee Problems such as component quality, lack of process parameters, and comprehensive monitoring of performance parameters have achieved the effect of improving manufacturing efficiency and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

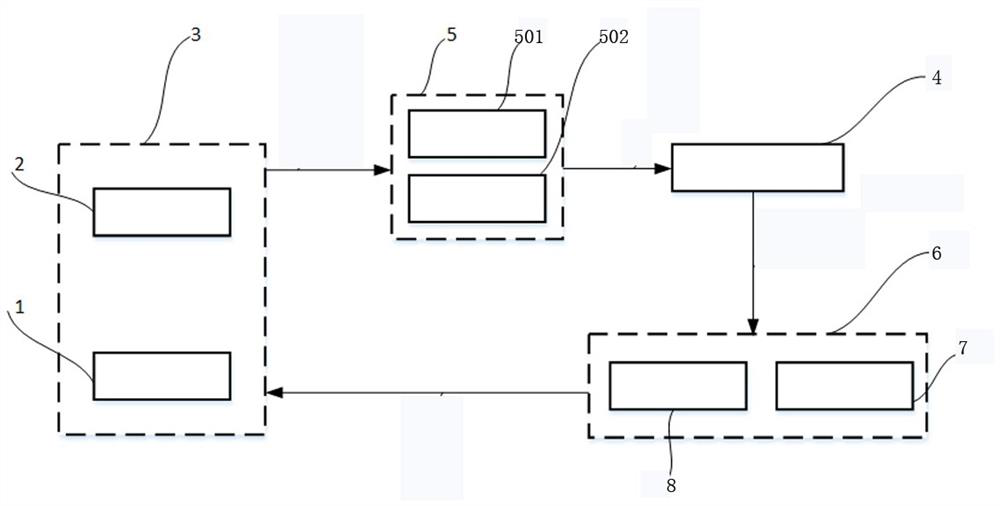

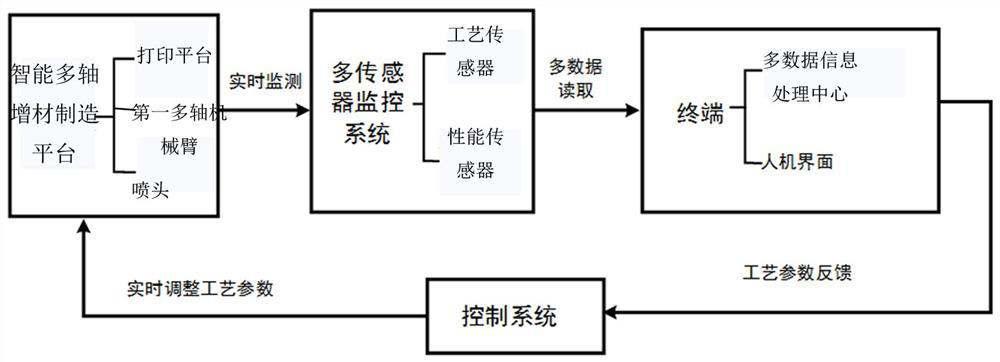

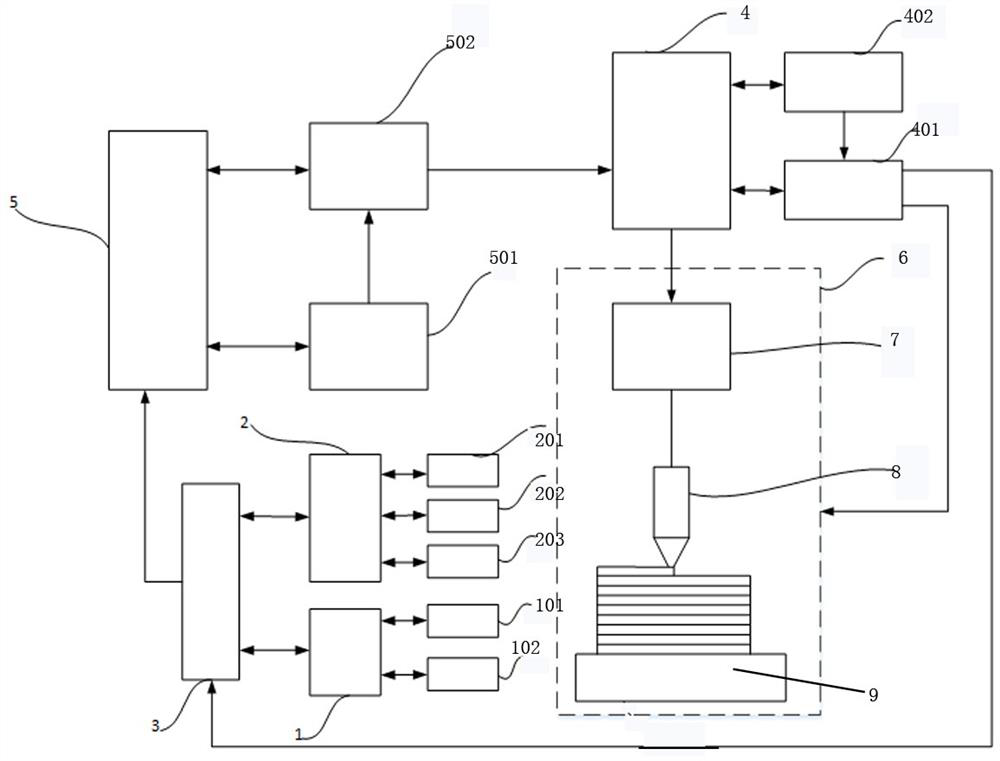

[0032] Further, this embodiment mainly introduces a multi-axis additive manufacturing intelligent monitoring and detection system integrating multi-sensors based on the present invention. The intelligent multi-axis additive manufacturing platform 6 includes a first multi-axis robotic arm 7, Print nozzle 8, motion platform 9, described print nozzle 8 is arranged on the front end of first multi-axis mechanical arm 7, and described print nozzle 8 is used for conveying manufacturing material; Motion platform 9 is used for supporting additive manufacturing parts, and described control The controller 401 of the system 4 is connected to and controls the first multi-axis robot arm 7 , the printing nozzle 8 , the motion platform 9 and the multi-sensor monitoring system 3 .

[0033] Further, in this embodiment, a multi-axis additive manufacturing intelligent monitoring and detection system integrating multi-sensors, its specific workflow is:

[0034] According to the data information of...

Embodiment 2

[0040] Further, this embodiment mainly introduces an intelligent cladding additive manufacturing monitoring and detection system integrating multi-sensors based on the present invention. The intelligent multi-axis additive manufacturing platform 6 includes a second multi-axis robotic arm 10, Coaxial powder feeding cladding head 11, multi-axis platform 12, and laser 13. The coaxial powder feeding cladding head 11, multi-axis platform 12, and laser 13 are all arranged at the front end of the second multi-axis mechanical arm 10. The multi-axis platform 12 is used to support cladding components, and the controller 401 of the control system 4 is connected to and controls the second multi-axis robot arm 10 , the coaxial powder feeding cladding head 11 , the multi-axis platform 12 and the laser 13 .

[0041] Further, in this embodiment, an intelligent cladding and additive manufacturing monitoring and detection system integrating multiple sensors, its specific workflow is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com