Composite foaming functional master batch as well as preparation method and application thereof

A technology of functional masterbatch and composite foaming, applied in the field of composite foaming functional masterbatch and its preparation, can solve the problems of low mechanical properties of shoe soles, complex and cumbersome operation, uneven distribution, etc., to make up for suddenness and uncontrollability Sex, avoid cumbersome operation, avoid dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

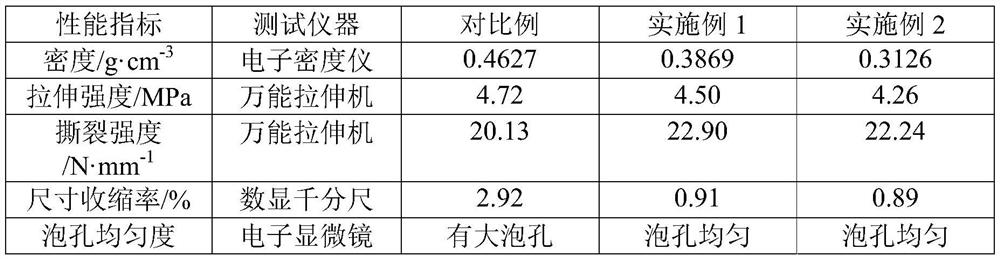

Examples

Embodiment 1

[0033] Composite foaming functional masterbatch, including the following components in parts by weight: 40 parts of EVA resin, foaming agent compound: 30 parts of expandable microspheres DU608, 30 parts of stearic acid modified baking soda (baking soda: hard The mass ratio of fatty acid is 1:2), 1 part of talcum powder.

[0034] The preparation method of composite foaming functional masterbatch comprises the following steps:

[0035] S1. Melt and mix the stearic acid and baking soda in the above parts by weight in an oven at 100° C., and stir continuously to obtain modified baking soda;

[0036] S2. Mix EVA, expandable microspheres DU608, modified baking soda, and talcum powder in an internal mixer at 60°C for 10 minutes according to the above weight parts;

[0037] S3. Add the mixed material into the single-screw extruder from the feeding port. The extrusion temperature of the single-screw extruder is 95° C., and the rotation speed is 100 r / min. Extrude and cut to obtain com...

Embodiment 2

[0039] Composite foaming functional masterbatch, comprising the following components in parts by weight: 40 parts of EVA resin, foaming agent compound: 30 parts of expandable microspheres DU608, 20 parts of stearic acid modified baking soda (baking soda: hard The mass ratio of fatty acid is 1:2), 10 parts of zinc stearate modified AC (the mass ratio of zinc stearate:AC is 4:6), and 1 part of talc powder.

[0040] The preparation method of composite foaming functional masterbatch comprises the following steps:

[0041] S1. Melt and mix the stearic acid and baking soda in the above parts by weight in an oven at 100° C., and stir continuously to obtain modified baking soda;

[0042] S2. Melt and mix the above-mentioned zinc stearate and AC in an oven at 100° C., and stir continuously to obtain modified AC;

[0043] S3. Mix EVA, expandable microspheres DU608, modified baking soda, zinc stearate, modified AC, and talcum powder in an internal mixer at 60°C for 10 minutes according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com