Heating crucible for vacuum evaporation and vacuum evaporation device

A crucible and vacuum technology is applied in the fields of heating crucibles for vacuum evaporation and vacuum evaporation devices, which can solve problems such as deterioration, inconvenient installation and maintenance, and small outlet, so as to prevent decomposition and deterioration, facilitate use and maintenance, and prevent cooling the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

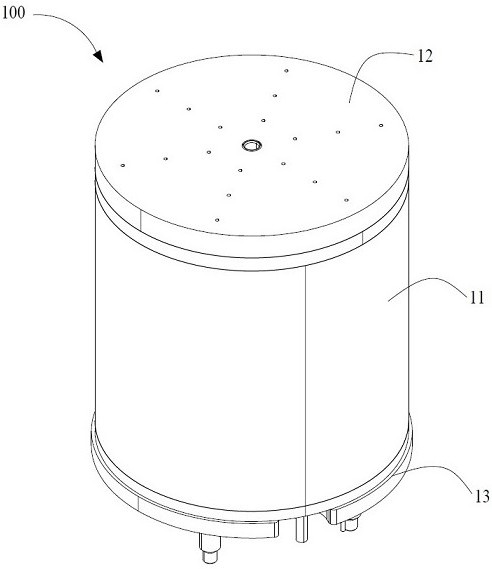

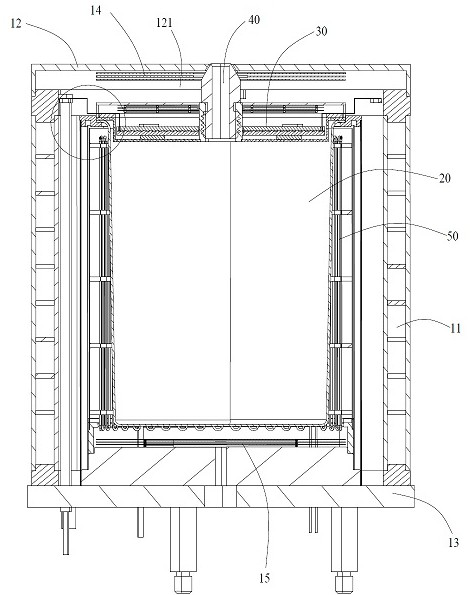

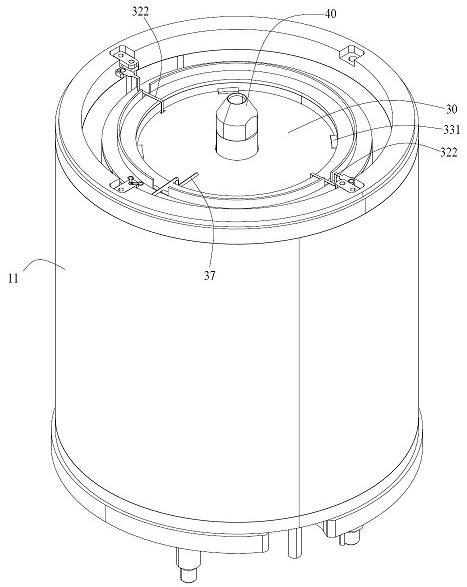

[0033] Please refer to Figure 1 to Figure 3 As shown, the present invention provides a vacuum evaporation device 100, which is installed in a vacuum chamber to coat a substrate to be evaporated in the vacuum chamber. The vaporized evaporation material ejected from the vacuum evaporation device 100 reaches the surface of the substrate to be evaporated and deposited thereon, and forms a thin film of the evaporated material on the surface of the substrate. The vacuum evaporation device 100 includes a heating crucible, a heat insulating shell 11 disposed on the outer periphery of the heating crucible, a heat insulating cover 12 , and a base 13 supporting the heating crucible and the heat insulating shell 11 .

[0034] Please refer to figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com