A method for controlling the drainage sand into the tundish in the continuous casting process

A process control and drainage sand technology, applied in the field of steel continuous casting, can solve the problems of poor controllability, cumbersome operation, and potential safety hazards, and achieve the effects of increasing the temperature of molten steel, ensuring automatic pouring, and avoiding molten steel pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

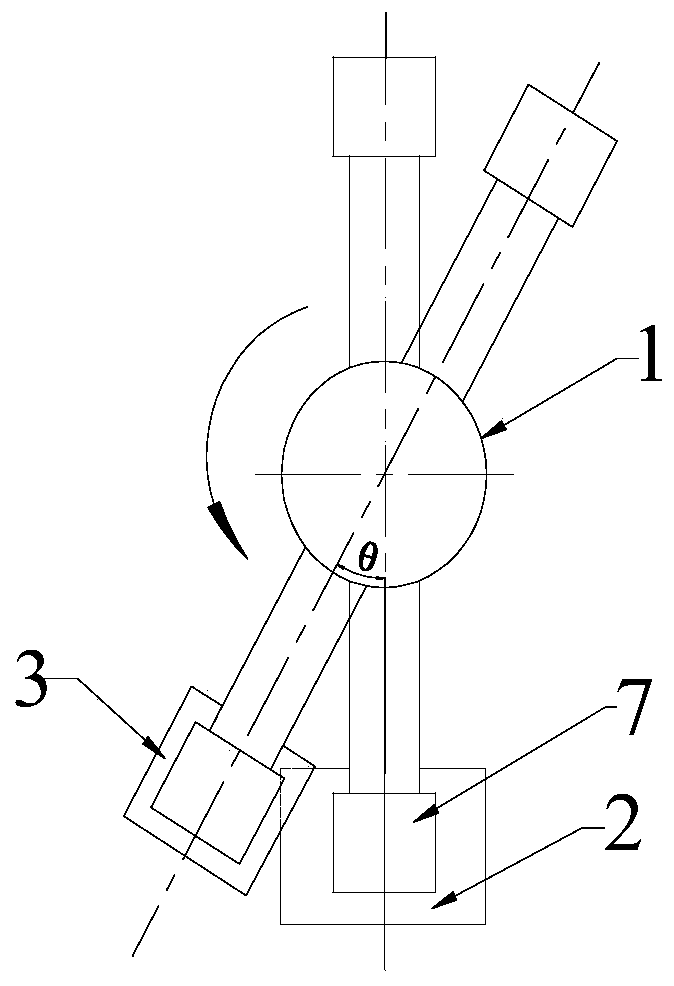

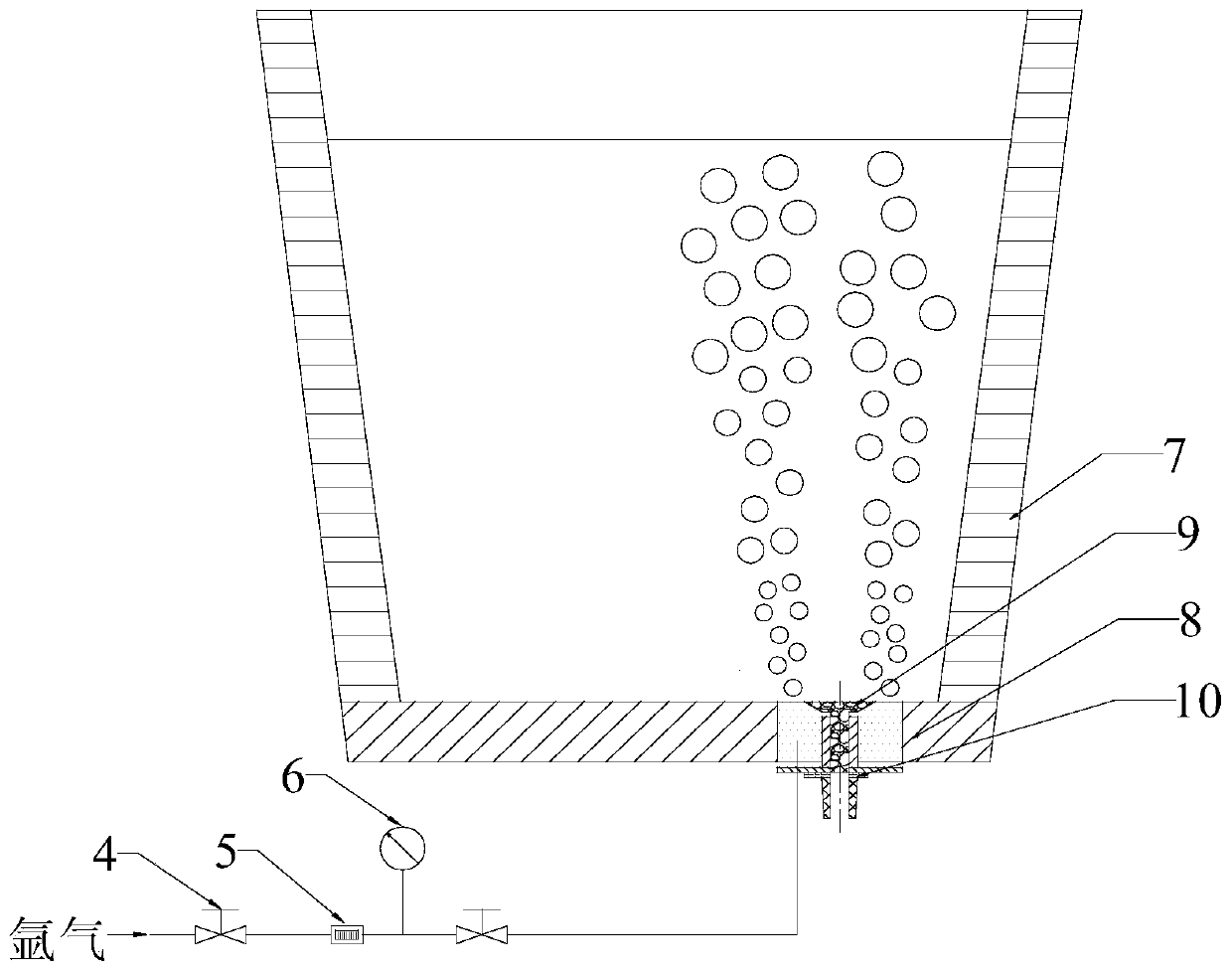

[0028] A method for controlling drainage sand to enter the tundish during continuous casting, such as figure 1 and 2 As shown, adopt 60 tons of ladles in the present embodiment; Specifically comprise the steps:

[0029] Step 1: 5 minutes before the pouring of the previous ladle is completed, blow argon gas into the molten steel in the ladle through the vent block 8 at the bottom of the ladle to the ladle 7 with drainage sand at the standby position of the ladle turret 1; when the ladle 7 When the ladle turret 1 rotates to an angle of 20° with the ladle pouring position, stop the rotation; among them: the pressure of blowing argon gas is: 0.3MPa, the flow rate is 5Nm 3 / h;

[0030] Step 2: Continuously blowing in argon gas to increase the temperature of the molten steel within 10cm directly above the vent block 8 by 2-5°C, and make the temperature of the molten steel in the ladle even. Place the steel scrap tank 3 under the sliding nozzle 10 of the ladle 7, open the sliding ...

Embodiment 2

[0037] A method for controlling drainage sand to enter the tundish during continuous casting, such as figure 1 and 2 As shown, adopt 120 tons of ladles in the present embodiment; Specifically comprise the following steps:

[0038] Step 1: 6 minutes before the pouring of the previous furnace ladle is completed, blow argon into the molten steel in the ladle through the breathable nozzle block 8 at the bottom of the ladle to the ladle 7 with drainage sand at the standby position of the ladle turret 1; when the ladle 7. When the ladle turret 1 rotates to an angle of 30° with the ladle pouring position, stop the rotation; among them: the pressure of blowing argon is: 0.4MPa, and the flow rate is 15Nm 3 / h;

[0039] Step 2: Continuously blowing in argon gas to increase the temperature of the molten steel within 10cm directly above the vent block 8 by 2-5°C, and make the temperature of the molten steel in the ladle even. Place the steel scrap tank 3 under the sliding nozzle 10 of ...

Embodiment 3

[0046]A method for controlling drainage sand to enter the tundish during continuous casting, such as figure 1 and 2 As shown, adopt 180 tons of ladles in the present embodiment; Specifically comprise the following steps:

[0047] Step 1: 10 minutes before the pouring of the previous ladle is completed, blow argon gas into the molten steel in the ladle through the breathable nozzle block 8 at the bottom of the ladle when the ladle 7 with drainage sand is in the standby position of the ladle turret 1; when the ladle 7. When the ladle turret 1 rotates to an angle of 50° with the ladle pouring position, stop the rotation; among them: the pressure of blowing argon is: 0.45MPa, and the flow rate is 25Nm 3 / h;

[0048] Step 2: Continuously blowing in argon gas to increase the temperature of the molten steel within 10cm directly above the vent block 8 by 2-5°C, and make the temperature of the molten steel in the ladle even. Place the scrap steel tank 3 under the sliding nozzle 10 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com