High-strength anchor net mortar pouring, reinforcing, leaking stoppage and repairing method for underground structure leakage

A technology of underground structure and repair method, which is applied in the repair of foundation structure, underwater structures, foundation structure engineering, etc. It can solve problems such as poor implementation method, structural force problem, cold joint pouring and vibration, etc., and achieve the appearance Good quality, easy access, less cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

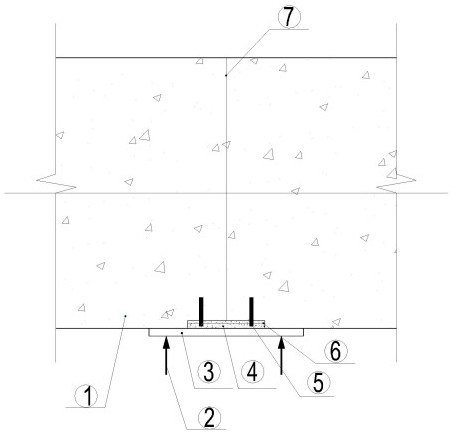

[0030] Below, taking the leakage repair of cracks in the side wall of a subway station as an example, the method for pouring leakage of underground structure cracks with high-strength anchor net mortar according to the present invention will be described in detail:

[0031] 1. Groove chisel hair. Cut and groove the concrete surface of about 50~100mm on both sides of the leaking crack with a groove depth of about 20mm, and remove the mortar layer on the original concrete surface.

[0032] 2. Temporary plugging of large flow leakage. In the cracks, especially the construction joints and deformation joints of the structure, the leakage is often serious. If the high-strength mortar is poured directly, it is easy to be washed away by the water flow and fail. For this reason, cement and water glass double liquid can be used comprehensively. slurry, epoxy resin or polyurethane, etc., or use a drainage tube for drainage to ensure that there is no large water seepage on the pouring su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com