Directional jet cooling PDC drill bit

A drill bit and sprinkler technology, which is applied to drill bits, liquid/gas jet drilling, drilling tools, etc., can solve the problems of severe cutting tooth wear, reduced thermal stability of cutting teeth, and affecting the life of PDC bit, so as to prevent thermal damage, The effect of prolonging life and improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

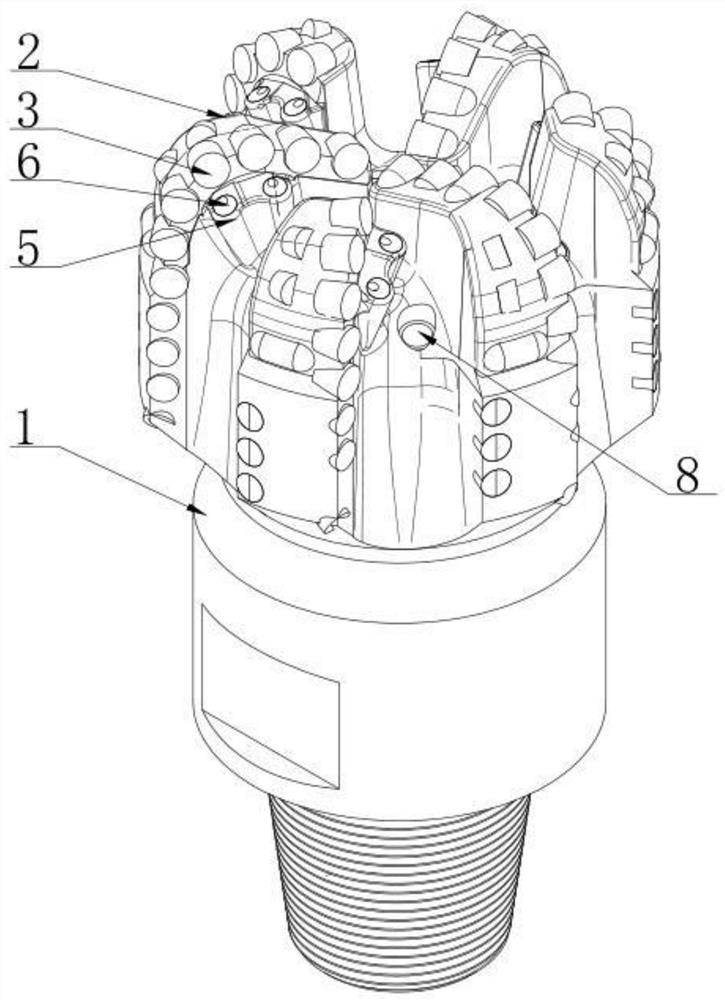

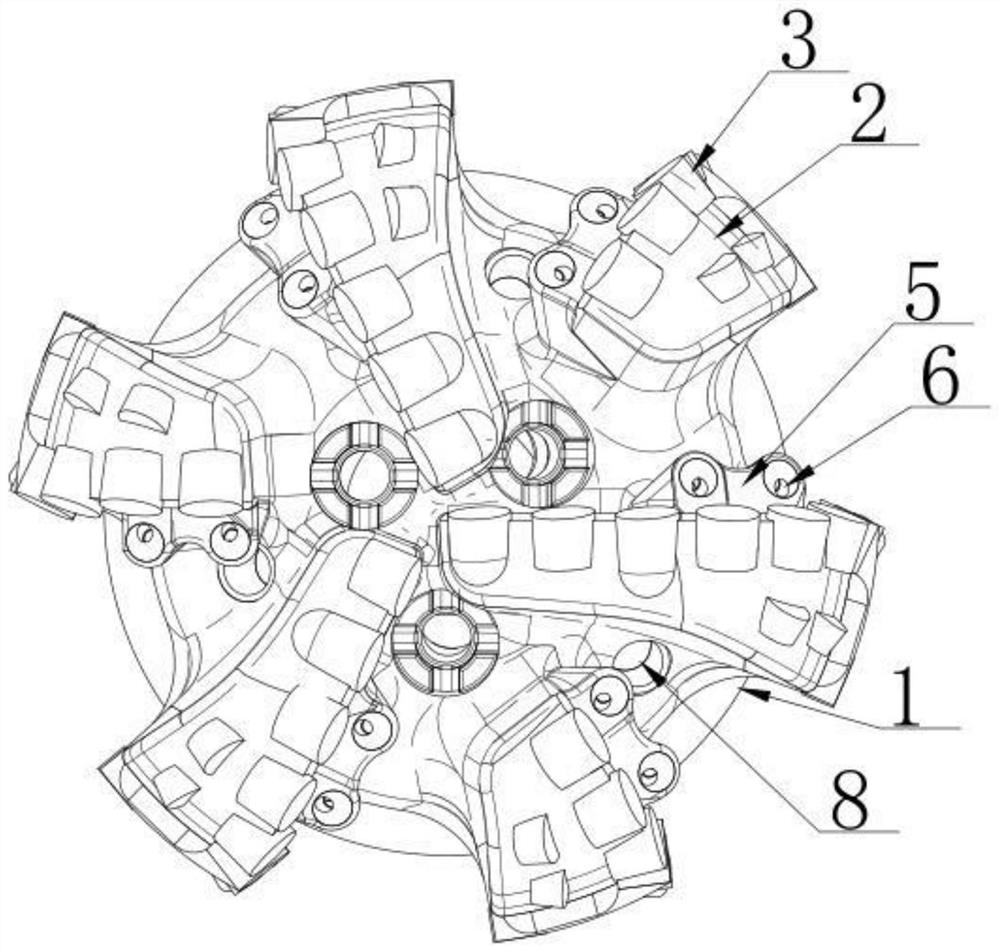

[0023] Such as figure 1 , figure 2 As shown, a kind of directional jet cooling PDC drill bit provided by the present invention comprises a drill body 1, several blades 2, several blades 2 are arranged at intervals along the circumference of the drill body 1, and each blade (2) lower end has a gage structure, and each blade 2 is provided with multiple groups of cutting teeth 3, multiple groups of cutting teeth 3 are arranged at intervals along the width direction of the blade 2, and multiple cutting teeth 3 in each group of cutting teeth 3 are arranged along the blade 2 The axial direction of the drill bit is evenly spaced, and one set of cutting teeth 3 is located on the edge of the blade 2 in the cutting direction, so that the cutting efficiency of the drill bit is higher.

[0024] The drill body 1 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com