Construction structure and process for controlling slope of underwater reef explosion slope through pre-splitting blasting

A technology of pre-splitting blasting and construction technology, which is applied to underwater structures, infrastructure engineering, blasting, etc., and can solve problems such as inability to meet construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

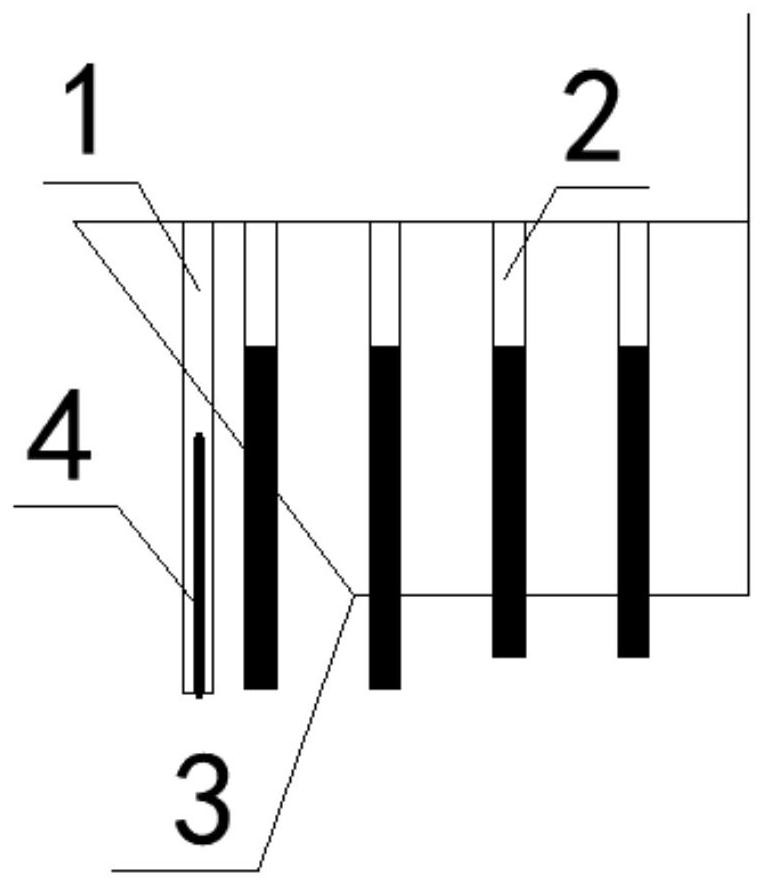

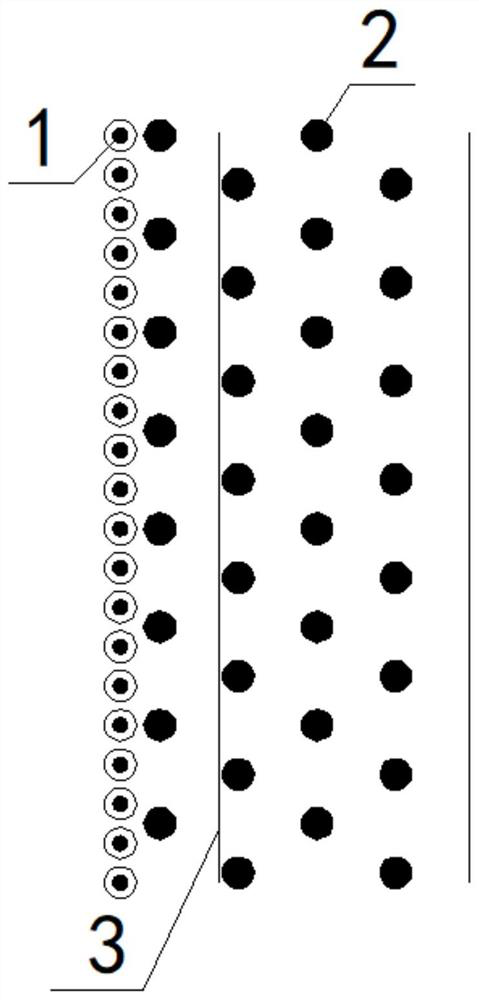

[0035] A construction technique of pre-splitting blasting to control the slope slope of underwater blasting reefs. The slope control adopts pre-splitting blasting, such as figure 1 , figure 2 As shown, the position of pre-splitting hole 1 is 2.5m away from the toe line of the slope, the super-depth of drilling is 1.6m, and the drilling spacing is 1.0m, the super-depth of the main blast hole 2 is 1.5m within the range of 2m from the toe line of the slope, and the rest Ultra-deep 1.0m, drilling distance 2.5m; main gun hole 2 is equipped with colloidal seismic source charges, charged according to 60-70% of the hole length, pre-splitting hole 1 charge is emulsified φ32 small charge, single row full On the steel bar, inject the medicine to the bottom of the hole; the pre-splitting hole 1 is detonated before the main gun hole 2; specifically, the following steps are included:

[0036] The first step: main gun hole construction

[0037] First, the main gun hole 2 is drilled acc...

Embodiment 2

[0056] The structure adopted in the construction technology of the pre-splitting blasting control underwater blasting reef slope slope described in a kind of embodiment 1, comprises pre-splitting hole 1, main gun hole 2 and the explosives packed in each hole, the position of said pre-splitting hole 1 3.2.5m away from the footline of the slope, the super-deep drilling is 1.6m, and the drilling distance is 1.0m. The drilling distance is 2.5m; the main blast hole 2 is equipped with colloidal seismic source charges, which are charged according to 60-70% of the hole length. Up and down the charge to the bottom of the hole; the pre-split hole 1 is detonated before the main gun hole 2.

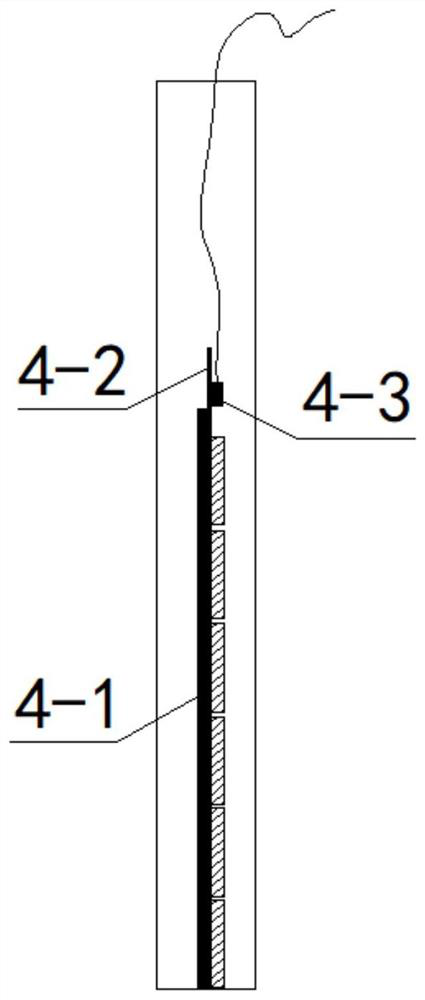

[0057] The pre-splitting hole 1 is filled with a small medicine roll 4-1, which is connected in series with a detonating cord 4-2 and bound on a steel bar, and is detonated with a double detonator 4-3; each tube of the seismic source charge contains 5kg of explosives , the diameter of the powder col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com