System and method for testing tensile property of soft hydrophilic material in normal saline

A technology of hydrophilic materials and normal saline, applied in the field of experimental mechanics of soft hydrophilic materials, can solve problems such as difficulties in loading and measuring soft hydrophilic materials, unusable contact extensometers, and inability to meet the loading stroke , to achieve the effects of easy production and promotion, reliable clamping device and measuring device, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below by way of examples. The embodiments are only used to illustrate the content of the present invention and are not limited thereto. Those skilled in the art, due to the technical inspiration involved in the present invention, adopt equivalent replacements or equivalent deformations to form technical solutions that fall within the scope of the present invention within the scope of protection.

[0039] The present invention will be further described below in conjunction with the specific implementation process. The soft hydrophilic material used is silicon hydrogel material.

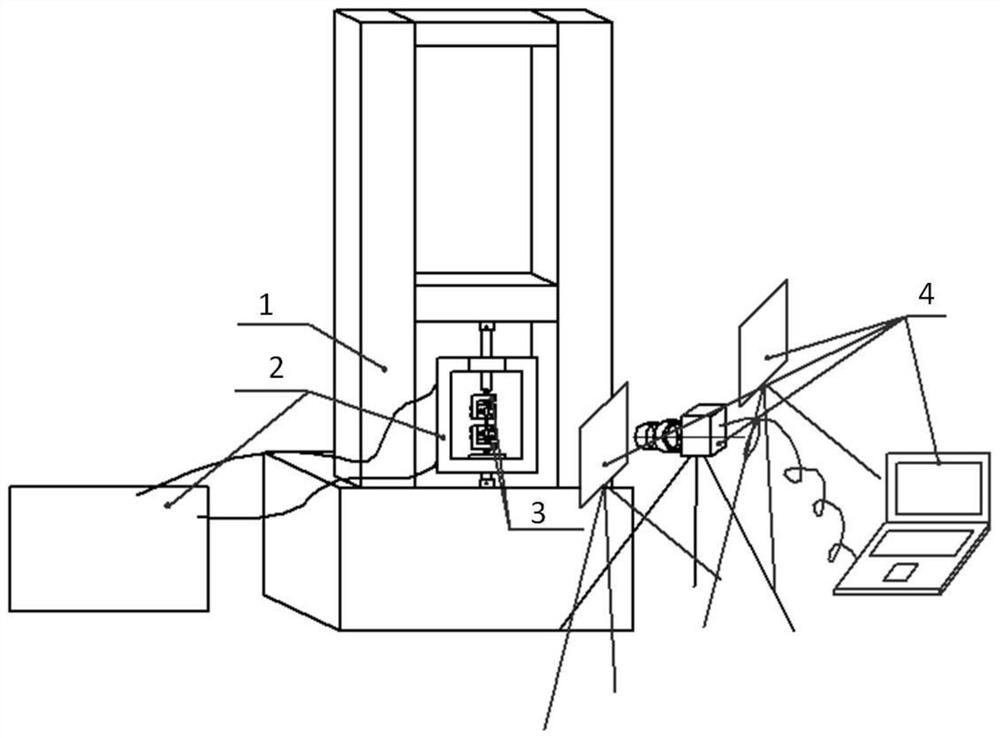

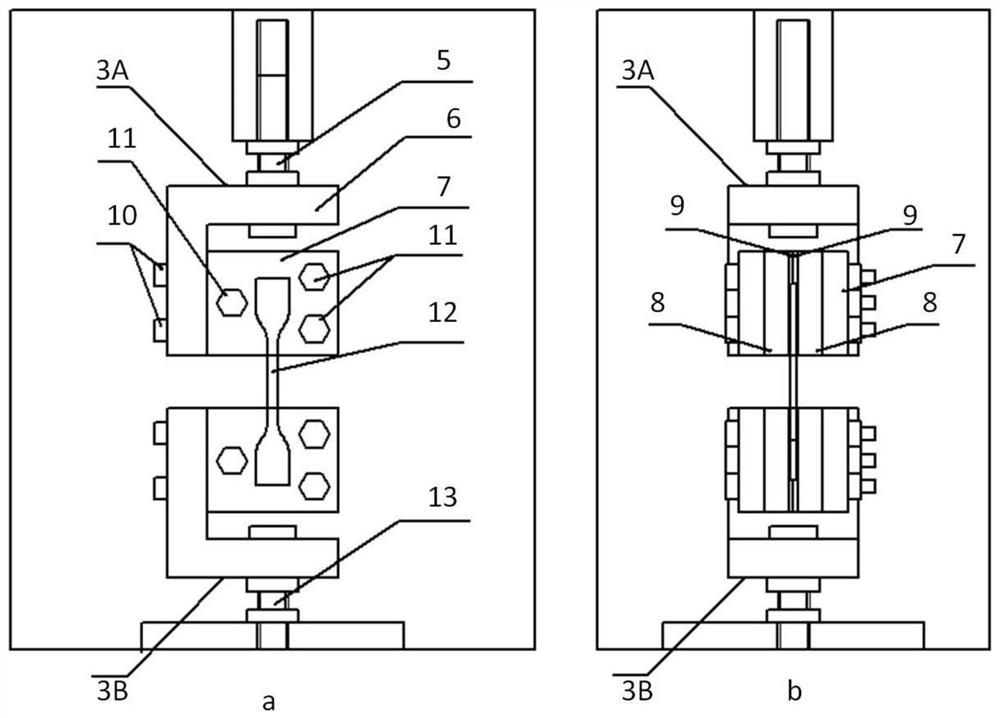

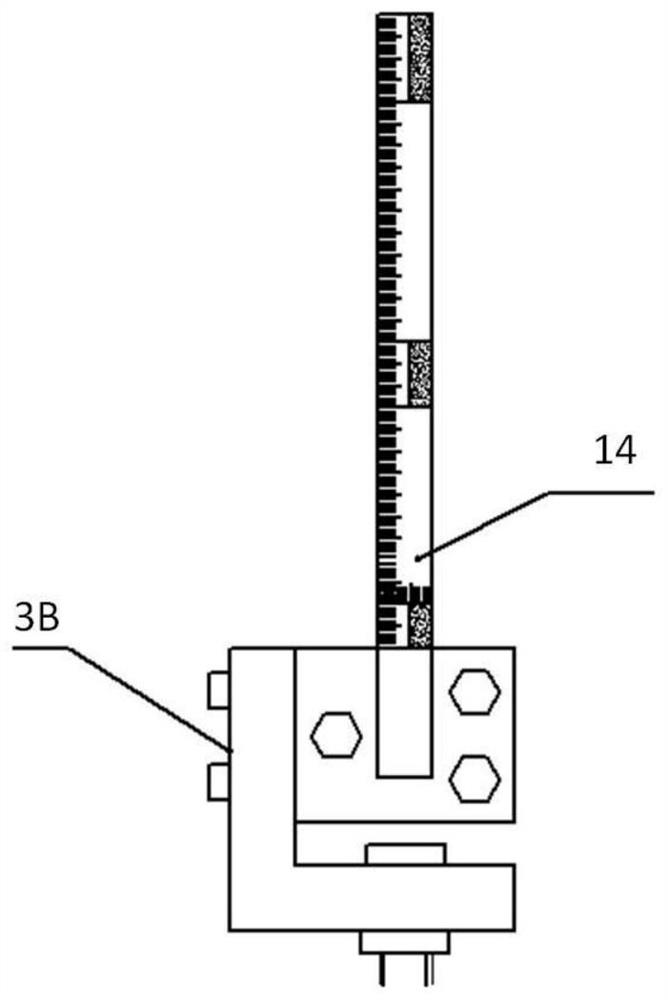

[0040] The installation and testing steps of the soft hydrophilic tensile property testing device in physiological saline based on digital image testing technology are as follows.

[0041] 1) Preparation of samples and speckles: prepare soft hydrophilic materials with reference to Type 2 samples in GB / T 528-2009, and then soak them in physiolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com