A test device for heat exchange tubes

A test device and heat exchange tube technology, applied in the field of heat exchange tubes, can solve problems such as errors in test results of heat exchange tubes, and achieve the effects of wide measurable range, reducing errors and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

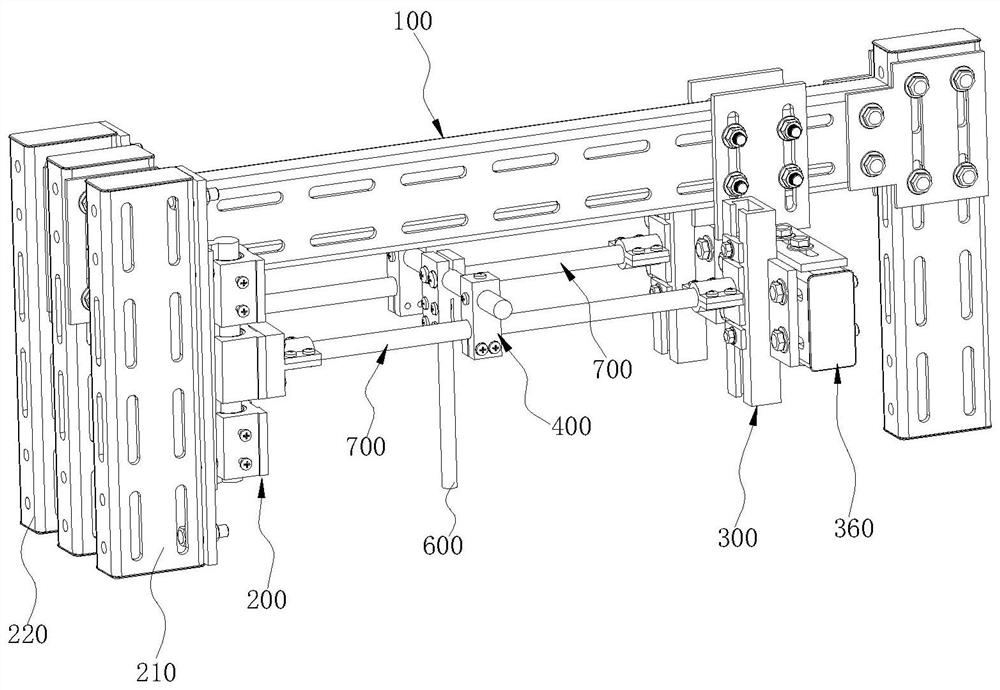

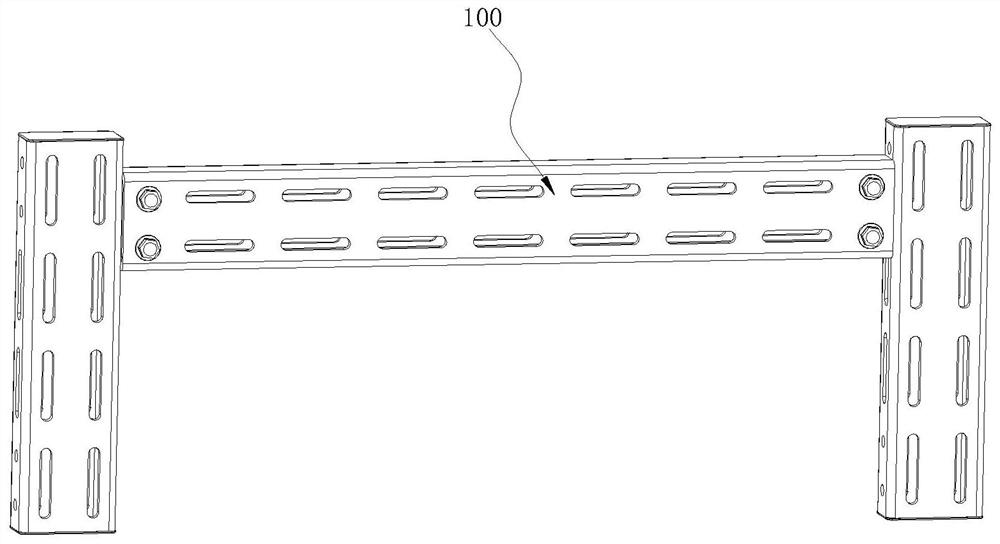

[0056] The fixing mechanism includes: a fixing frame 100; a first fixing seat 210 and a second fixing seat 220, the first fixing seat

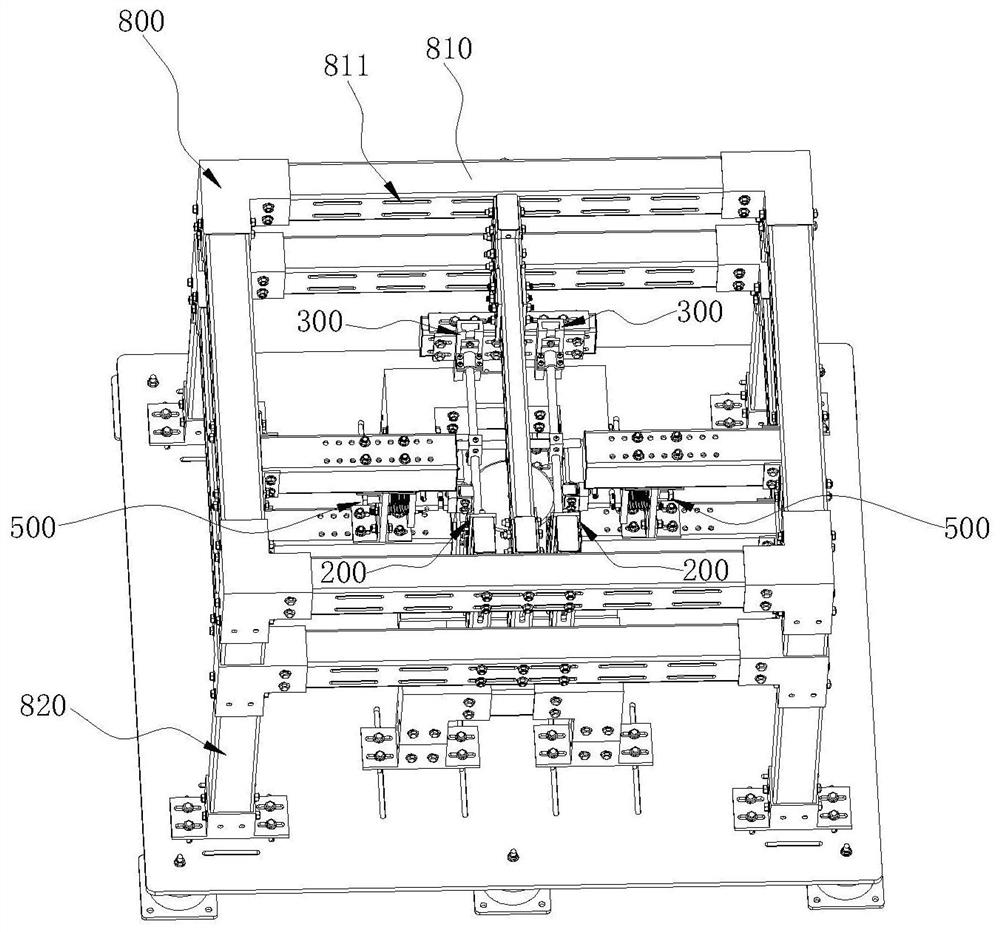

[0057] The preloading force loading mechanism includes two preloading force loading units 500, and each preloading force loading unit 500 is used for

[0059] In the case where the balance assembly 400 is not provided, when the heat exchange tube 700 is preloaded, the lateral direction of the heat exchange tube 700 will be caused.

[0061] Further, the relative position between the sliding seat 360 and the fixing frame 100 can be adjusted, so that the first clamping assembly

[0062] The relative positions between the two second clamping assemblies 300 and the sliding seat 360 can be adjusted;

[0065] The first clamping assembly 200 clamps either end of the heat exchange tube 700, and the second clamping assembly 300 clamps the heat exchange tube 700.

[0066] Before the heat exchange tube 700 is tested, the heat exchange tube 700 needs to be fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com