High-protein cheese egg roll and preparation method thereof

A production method, egg roll technology, applied in dairy products, cream preparations, bacteria used in food preparation, etc., can solve problems such as low solubility and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

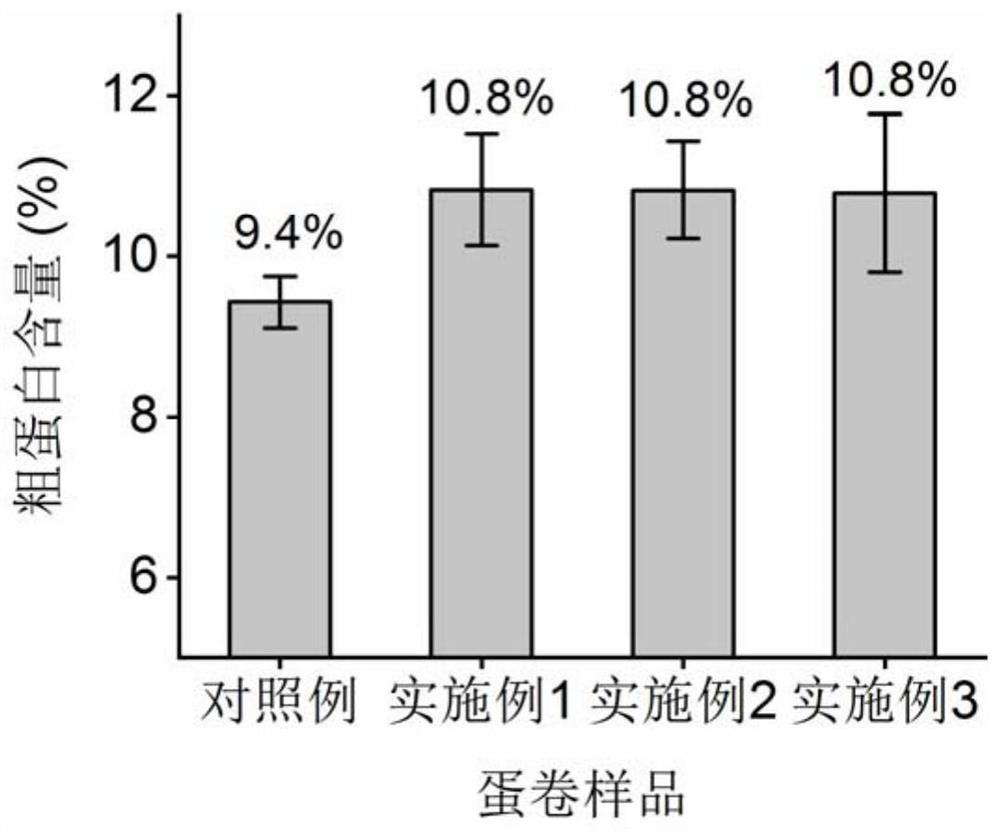

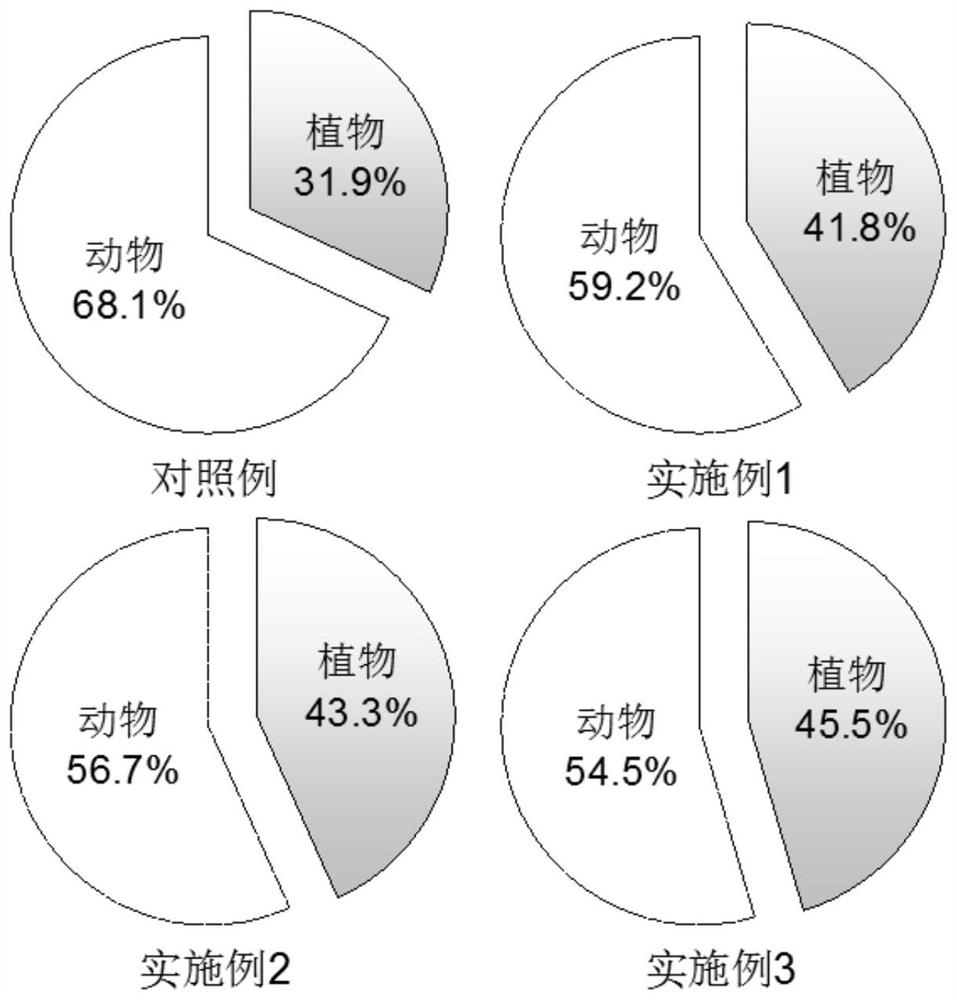

Embodiment 1

[0037] A method for making cheese omelets, comprising the steps of:

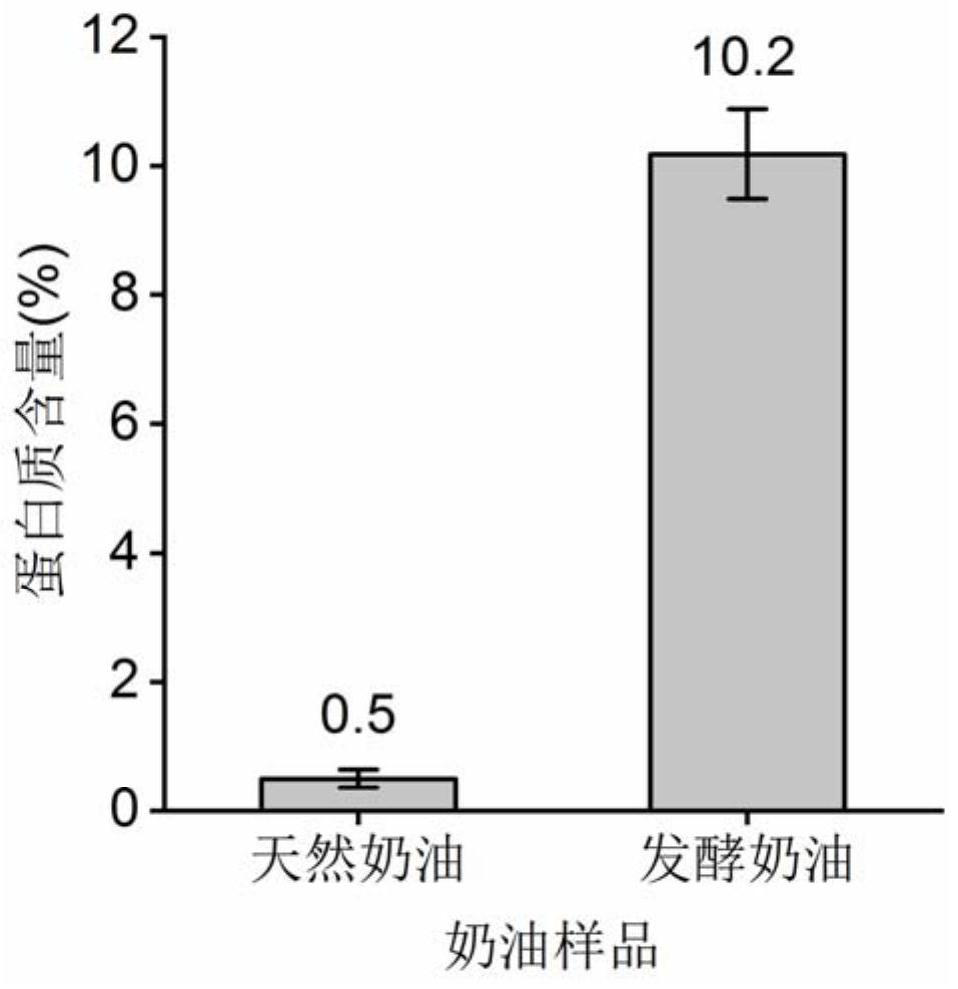

[0038] (1) Heat 270g of anhydrous butter at 40°C until completely melted; keep the temperature of the melted butter at 40°C constant, add 30g (in terms of its solid content; the same below) of soybean protein isolate enzymatic hydrolyzate, and stir slowly until fully dispersed; Add fermented strains to the obtained high-protein cream, stir slowly until uniformly dispersed; ferment at a constant temperature of 40°C for 24 hours; raise the temperature to 95°C to inactivate the fermented strains to obtain fermented cream;

[0039] (2) Weigh 60g of white sugar and dissolve it in a small amount of water, add 300g of high-protein fermented cream, 300g of cheese, 600g of egg liquid, and 60g of sea salt in turn, stir at high speed for 5 minutes, add 800g of low-gluten wheat flour, stir at low speed and mix until it becomes uniform After the slurry is ready for use.

[0040] (3) Send the egg roll slurry to the egg r...

Embodiment 2

[0045] A method for making cheese omelets, comprising the steps of:

[0046] (1) Heat 360g of anhydrous butter at 40°C until it melts completely; keep the temperature of the melted butter at 40°C constant, add 40g of soybean protein isolate hydrolyzate, and stir slowly until fully dispersed; add fermentation strains to the obtained high-protein butter, slowly Stir until evenly dispersed; ferment at a constant temperature of 40°C for 36 hours; raise the temperature to 95°C to inactivate the fermentation strains to obtain fermented cream;

[0047] (2) Weigh 60g of white sugar and dissolve it in a small amount of water, add 400g of high-protein fermented cream, 300g of cheese, 600g of egg liquid, and 60g of sea salt in turn, stir at high speed for 5 minutes, add 800g of low-gluten wheat flour, stir at low speed and mix until it becomes uniform After the slurry is ready for use.

[0048] (3) Send the egg roll slurry to the egg roll forming machine to make egg rolls. After the eg...

Embodiment 3

[0051] A method for making cheese omelets, comprising the steps of:

[0052] (1) Heat 450g of anhydrous butter at 40°C until it melts completely; keep the temperature of the melted butter at 40°C constant, add 50g of soybean protein isolate hydrolyzate, and stir slowly until fully dispersed; add fermentation strains to the obtained high-protein cream, slowly Stir until evenly dispersed; ferment at a constant temperature of 40°C for 48 hours; raise the temperature to 95°C to inactivate the fermentation strains to obtain fermented cream;

[0053] (2) Weigh 60g of white sugar and dissolve it in a small amount of water, add 500g of high-protein fermented cream, 300g of cheese, 600g of egg liquid, and 60g of sea salt in turn, stir at high speed for 5 minutes, add 800g of low-gluten wheat flour, stir at low speed and mix until it becomes uniform After the slurry is ready for use.

[0054] (3) Send the egg roll slurry to the egg roll forming machine to make egg rolls. After the egg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com