Needle tubing type silicone grease processing device capable of automatically covering

A processing device and needle tube technology, which is applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of low manual operation efficiency, inability to accurately control the amount of silicone grease, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

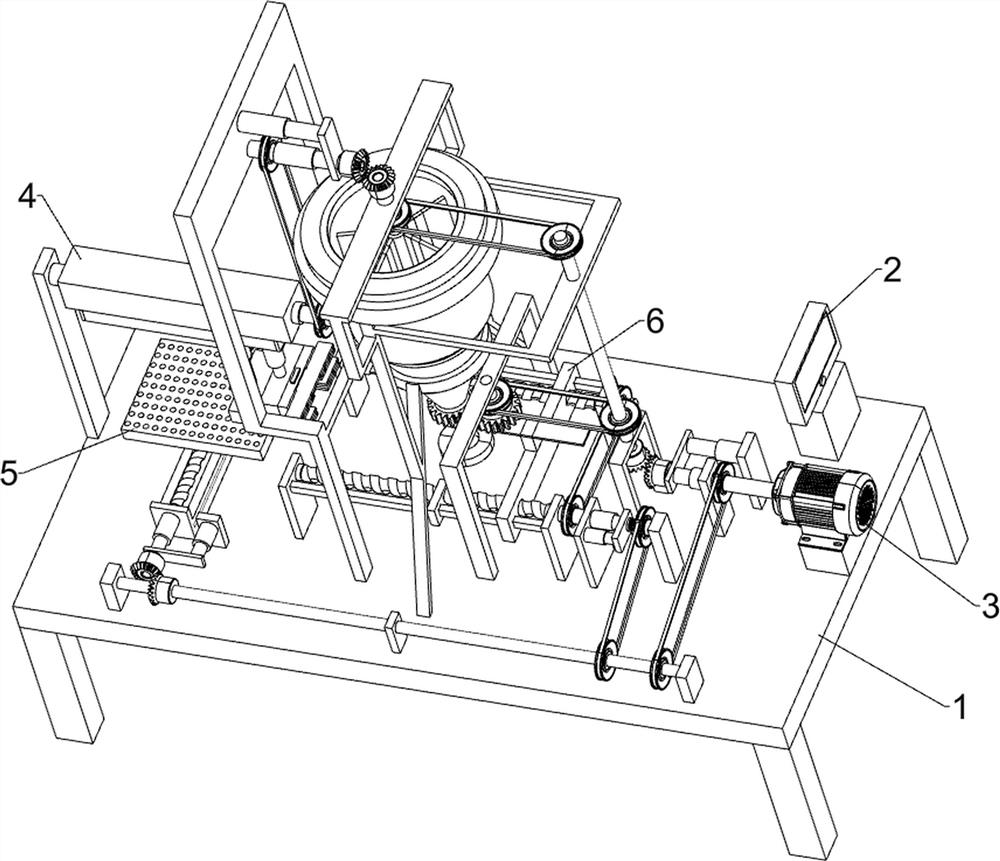

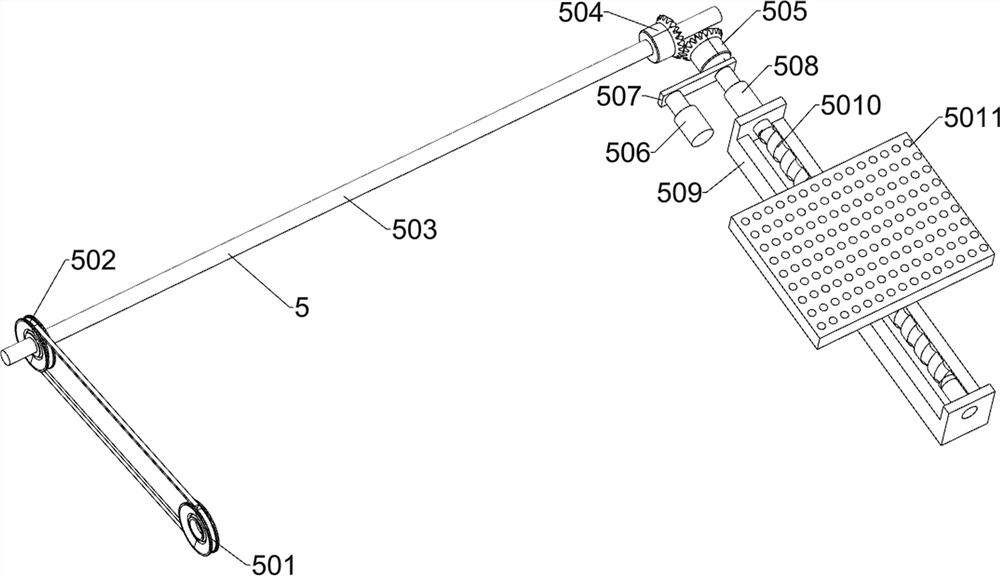

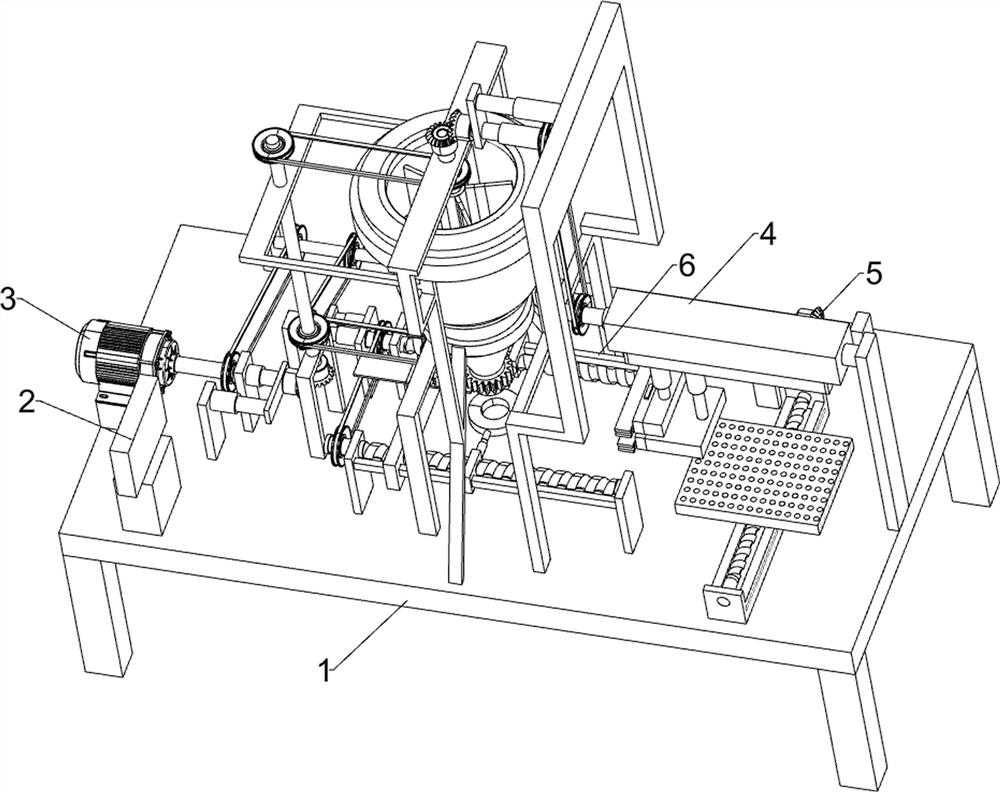

[0027] A needle tube type silicone grease processing device that can automatically cover, such as Figure 1-6 As shown, it includes workbench 1, control panel 2, unloading mechanism 3, silicone grease suction mechanism 4, upper cover mechanism 5 and transport mechanism 6; workbench 1 is connected with control panel 2; workbench 1 and unloading mechanism 3 phase connection; workbench 1 is connected with silicone grease suction mechanism 4; workbench 1 is connected with upper cover mechanism 5; workbench 1 is connected with transportation mechanism 6; unloading mechanism 3 is connected with silicone grease suction mechanism 4; The unloading mechanism 3 is connected with the upper cover mechanism 5 ; the upper cover mechanism 5 is connected with the transport mechanism 6 .

[0028] Before the device is used, the silicone grease production equipment is manually installed above the silicone grease suction mechanism 4, and the position is adjusted, and the cover on the upper cover m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com