Use method of automatic drill rod loading and unloading drilling machine

A technology for automatic loading and unloading of drill pipes, applied to drilling equipment and methods, drill pipes, drill pipes, etc., to achieve the effect of improving safety and use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

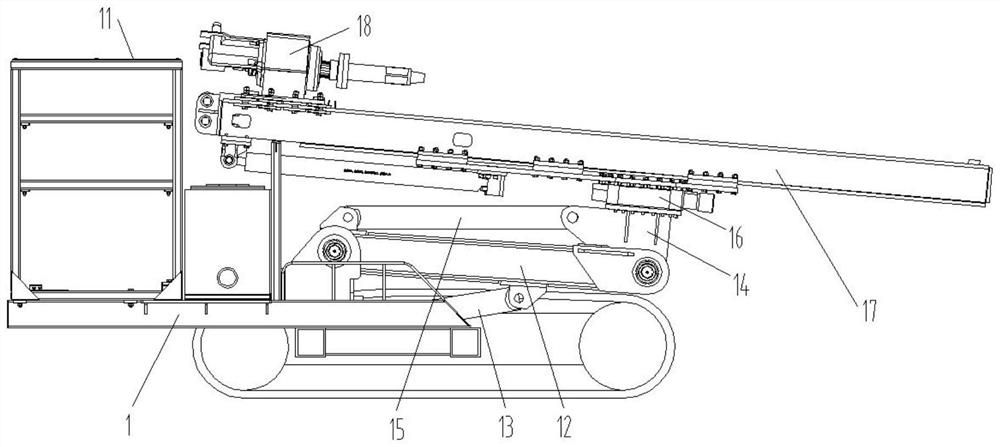

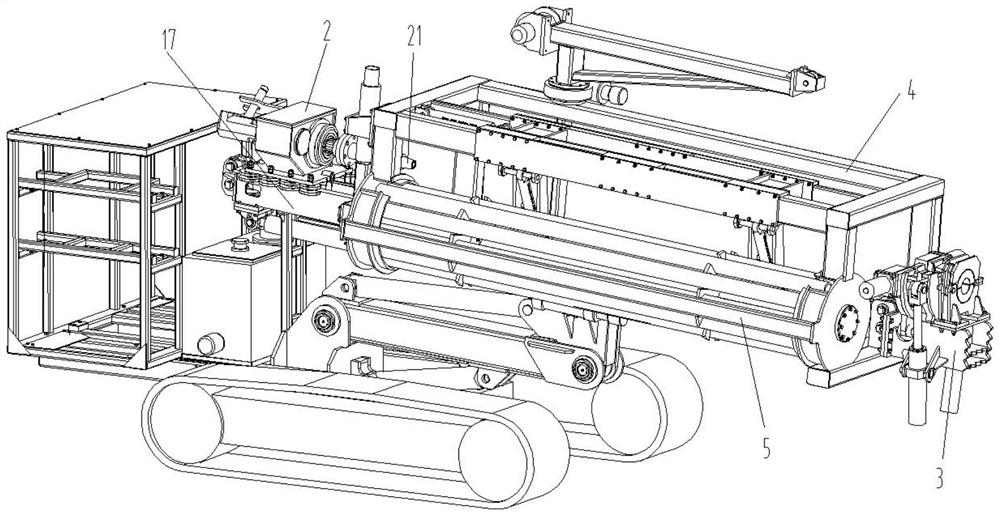

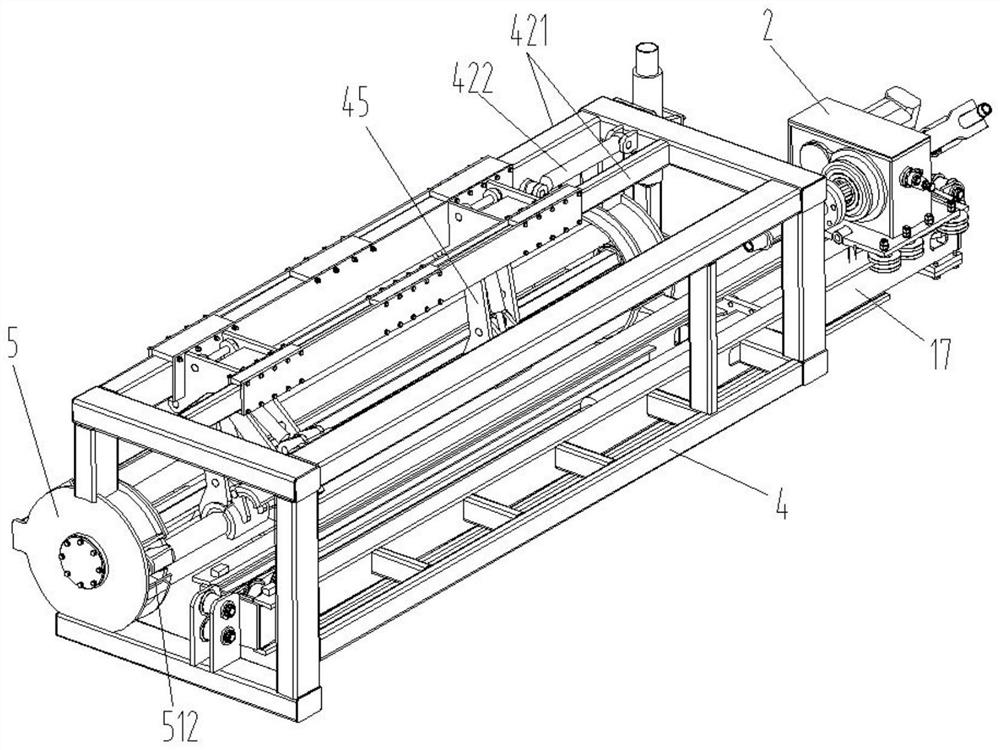

[0067] A method for using an automatic loading and unloading drill pipe rig in a specific embodiment is based on a multi-drilling rig that can automatically load and unload drill pipes, please refer to Figure 2-Figure 4 , the multi-drilling rig that can automatically load and unload drill pipes includes a mast base frame 17, a power head 2 can be reciprocally slidably connected to the mast base frame 17, and an output joint 21 is connected to the front end of the main shaft of the power head 2; the output joint One end of the mast base frame 17 facing 21 is connected with a clamping and breaking device 3, and the clamping and breaking device 3 includes a base 30 and is fixedly connected to the end of the mast base frame 17 through the base 30, the base 30 is provided with a fixed clamping unit 32 for clamping the drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com