Novel hydrogenation gun sealed by spring seal

A new type of pan-plug sealing technology, applied in the field of new energy hydrogen fuel cell vehicles, can solve the problems of insufficient sealing, gas leakage, low service life, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

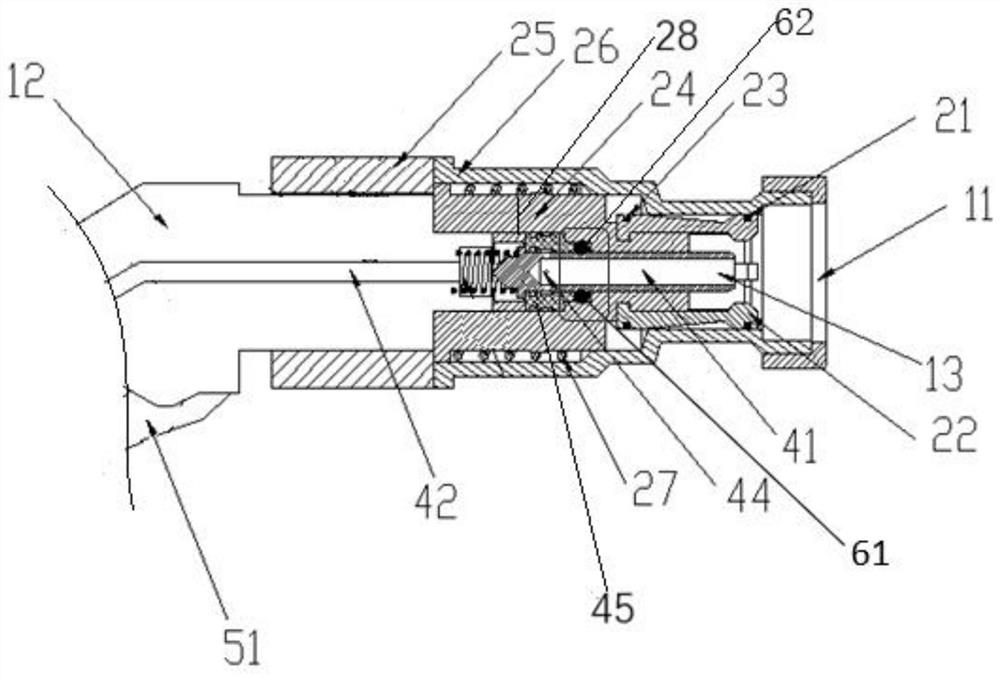

[0023] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

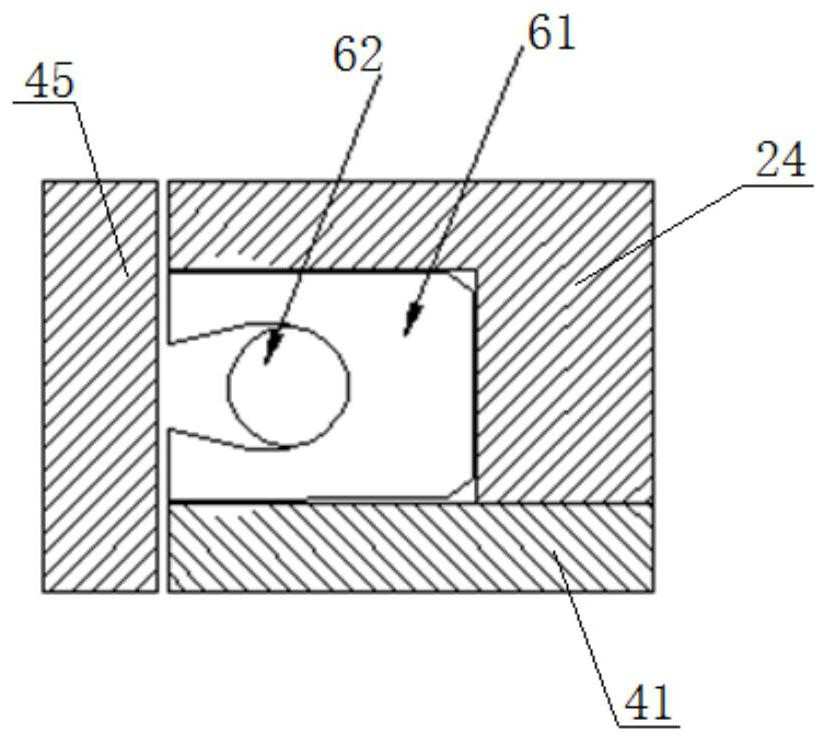

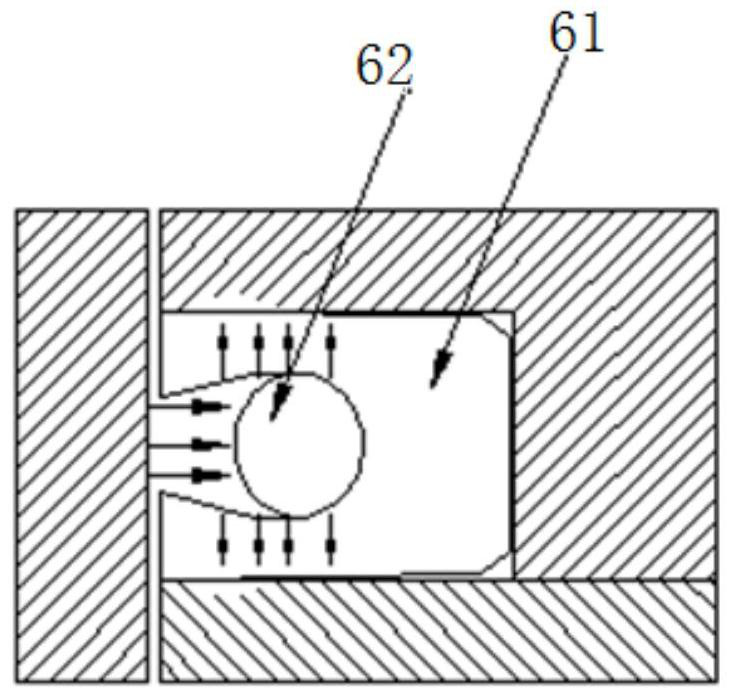

[0024] Such as figure 1 , figure 2 As shown, the interface adopts a double mechanical locking mechanism during hydrogenation, which will ensure the safe connection of the interface. The double mechanical locking structure includes the second shaft sleeve 26, the jaws 22 arranged near the inner wall of the second shaft sleeve 26, and the two jaws 22 respectively. The first hoop spring 21 and the second hoop spring 23 at the end, the second bushing 26 is provided with a bushing 24, the bushing 24 is also connected with the claw 22, the outer end of the second bushing 26 is connected with a bushing one 25, the bushing 24 is connected on the inner wall of the axle sleeve through several return springs; the outer end of the axle sleeve two is also provided with a protective sleeve 11.

[0025] There is a pressure relief ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com