DIC-based tooth root bending stress detection system and method in RV reducer gear engagement process

A technology of meshing process and bending stress, applied in the direction of applying stable bending force to test the strength of materials, instruments, measuring devices, etc., can solve the problems of reducing the structural strength of gear teeth, complex operation of gear bending fatigue test, and inaccurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0045] Example.

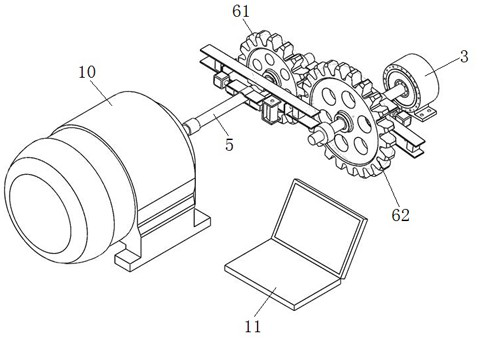

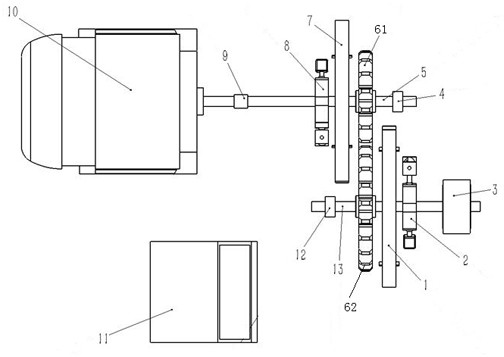

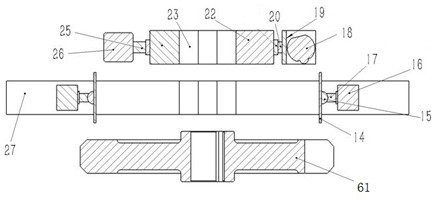

[0046] see Figure 1 to Figure 6 .

[0047] The embodiment discloses a DIC-based system for detecting the bending stress of the dedendum during the gear meshing process of the RV reducer, which is used for real-time detection of the bending stress at the tooth root during the meshing process of a pair of gears. In this embodiment, a pair of intermeshing gears are driven by a motor 10, and speckle is sprayed at the designated tooth root of each gear, and the speckle spraying area is determined according to the 30° tangent method, refer to Figure 5 shown.

[0048] The detection system includes a magnetic torque motor power device 3 , two sets of DIC equipment, two photoelectric encoders and a hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com