An insulation skin separator for equal slitting of waste cables

A technology for waste cables and insulating skins, which is applied in the field of insulating skin separators for volume cutting, can solve the problems of high labor intensity and low efficiency, and achieve the effect of easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

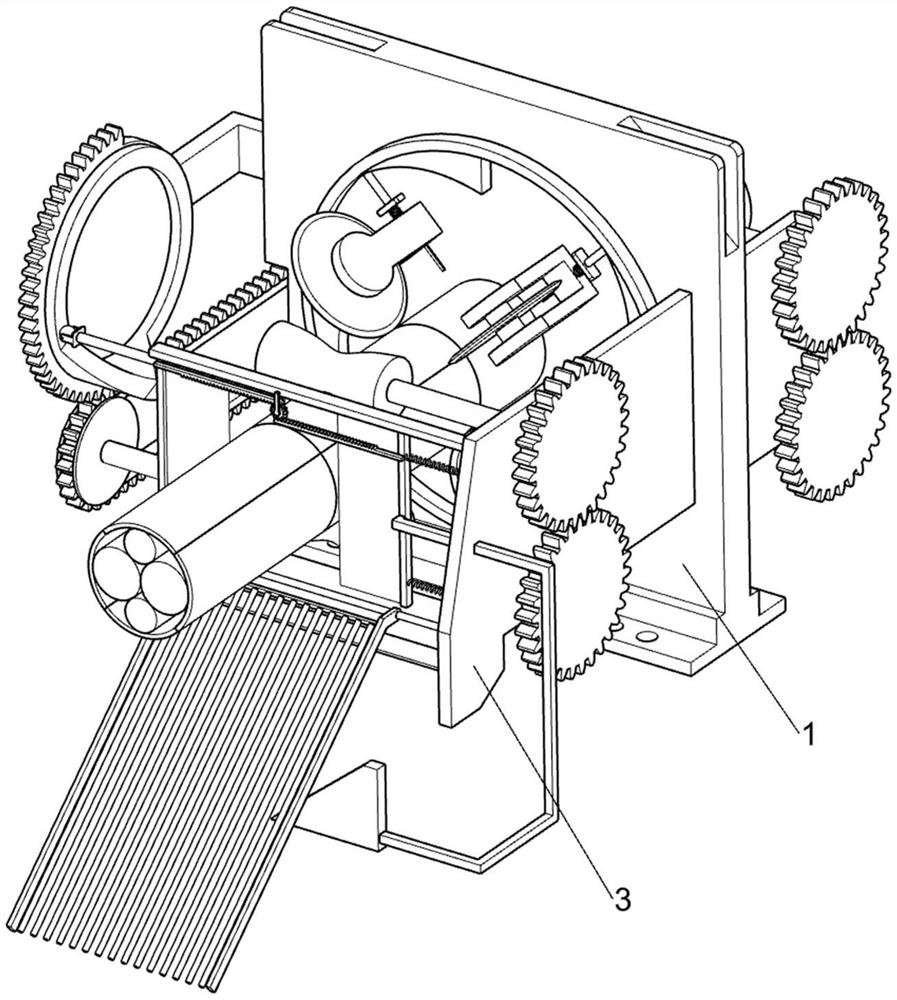

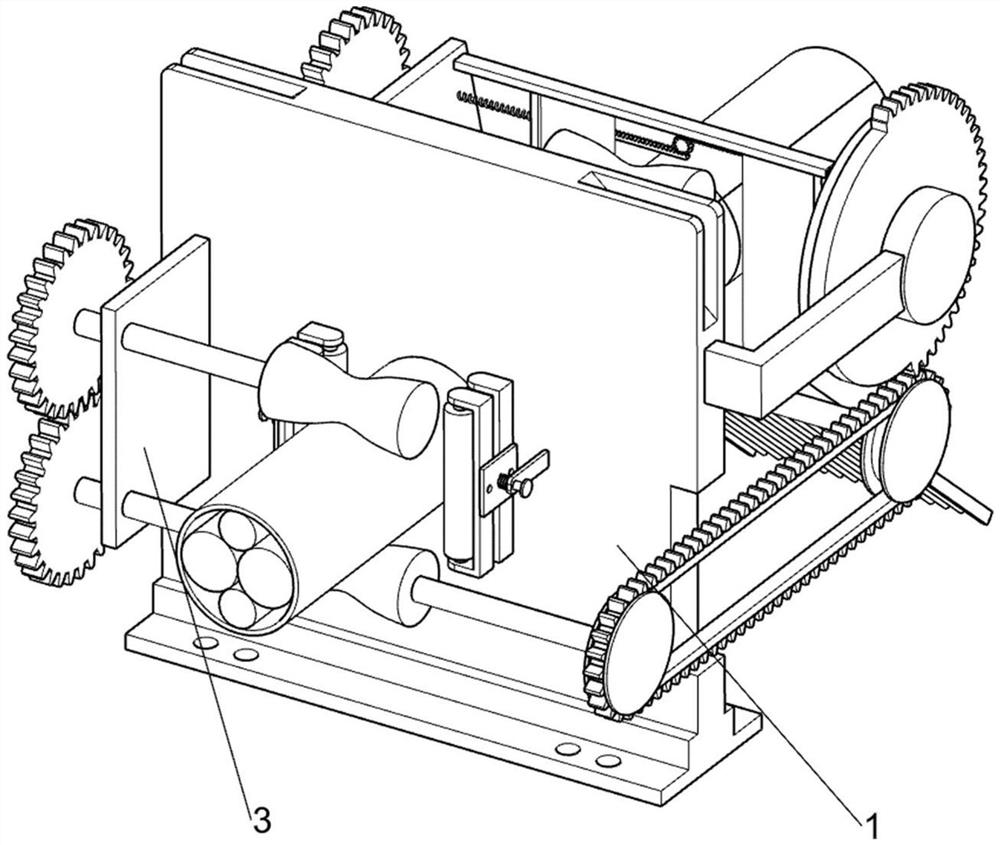

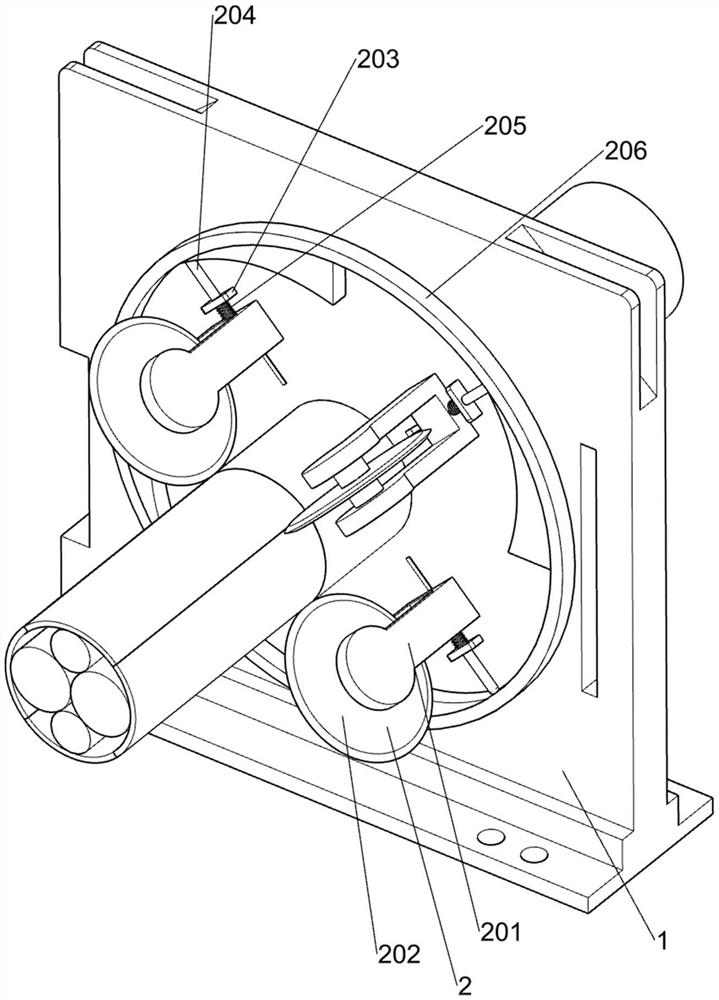

[0026] A kind of insulation skin separating machine for waste and old cable equivalent slitting, such as Figure 1-7 As shown, it includes a guide seat plate 1, a cutter position adjustment mechanism 2, a mounting plate 3, a cable support conveying mechanism 4, a cable cutting mechanism 5 and a cable sheath swing separation mechanism 6, and the cutter position adjustment mechanism 2 is located at On the guide seat plate 1, the cutter position adjustment mechanism 2 is used to make the cutting disc 202 just cut the insulation of the cable, and divide the insulation into four parts. The guide seat plate 1 is fixedly connected with the installation plate 3, and the cable The supporting conveying mechanism 4 is arranged on the mounting plate 3, the cable supporting conveying mechanism 4 is used to drive the cable to move in a direction close to the cutter plate 502, the cable cutting mechanism 5 is arranged on the mounting plate 3, and the cable cutting mechanism 5 is used for To ...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 5 As shown, it also includes a support plate 7, a flattening roller frame 8 and a third compression spring 9, the support plate 7 is symmetrically fixed on the side of the guide seat plate 1 away from the cutter plate 502, and the support plate 7 is used to support the flattening The roller frame 8 and the third compression spring 9, and the flattening roller frame 8 are slidably arranged on the support plate 7 respectively, and the flattening roller frame 8 is used to squeeze the cable, so that the cable is squeezed more flat, which is convenient for subsequent alignment. When the cable is cut, a third compression spring 9 is connected between the support plate 7 and the flattening roller frame 8, and the third compression spring 9 is used to drive the flattening roller frame 8 to move and reset.

[0034] When the cable is in contact with the flattening roller frame 8, it will squeeze the two flattening roller frames 8 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com