A permanent magnet external rotor submersible pump

A technology of submersible electric pump and outer rotor, which is applied in the direction of magnetic circuit rotating parts, pumps, magnetic circuits, etc., can solve the problems of large water friction loss, low efficiency of submersible electric pump unit, and reduced insulation thickness, so as to improve performance, Effects of saving metal consumption and reducing insulation thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with examples, as will be described, as described herein, only the embodiments of the invention, not all embodiments. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

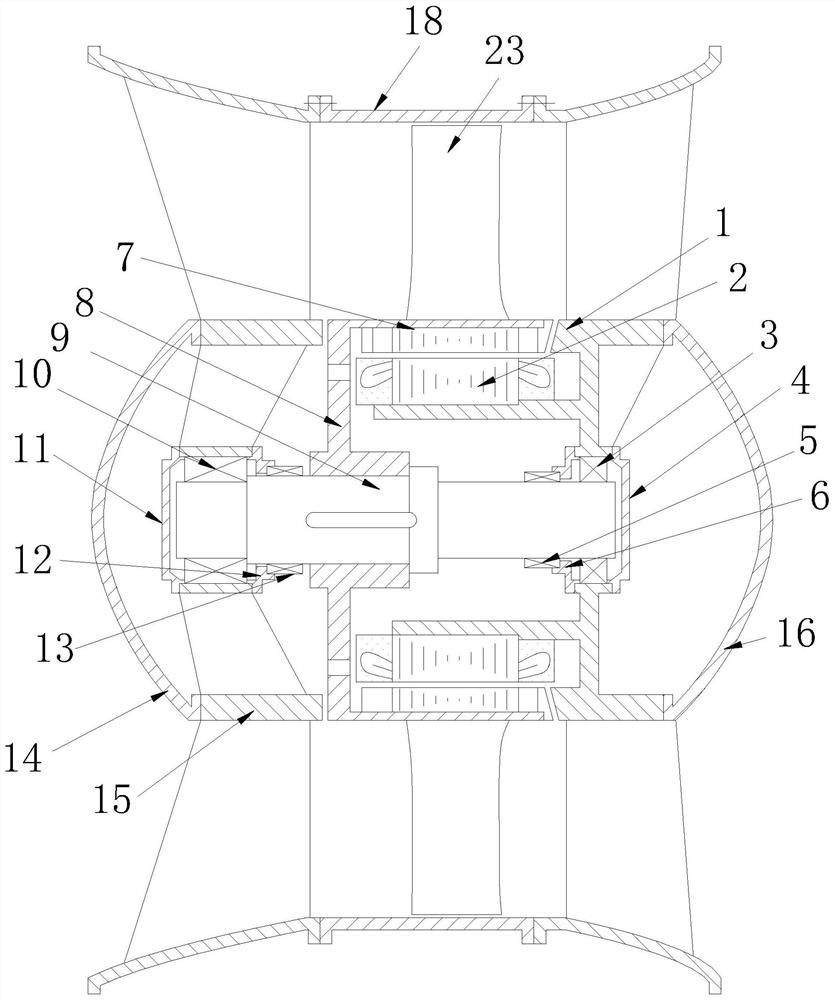

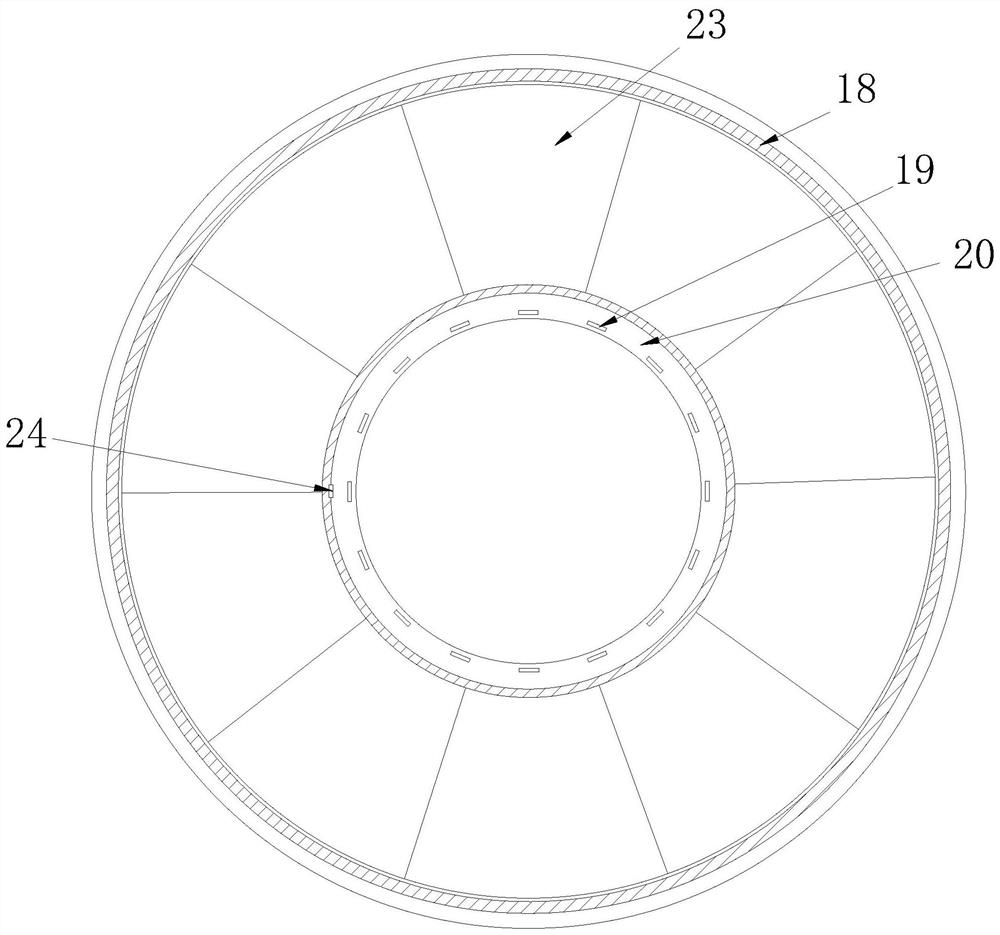

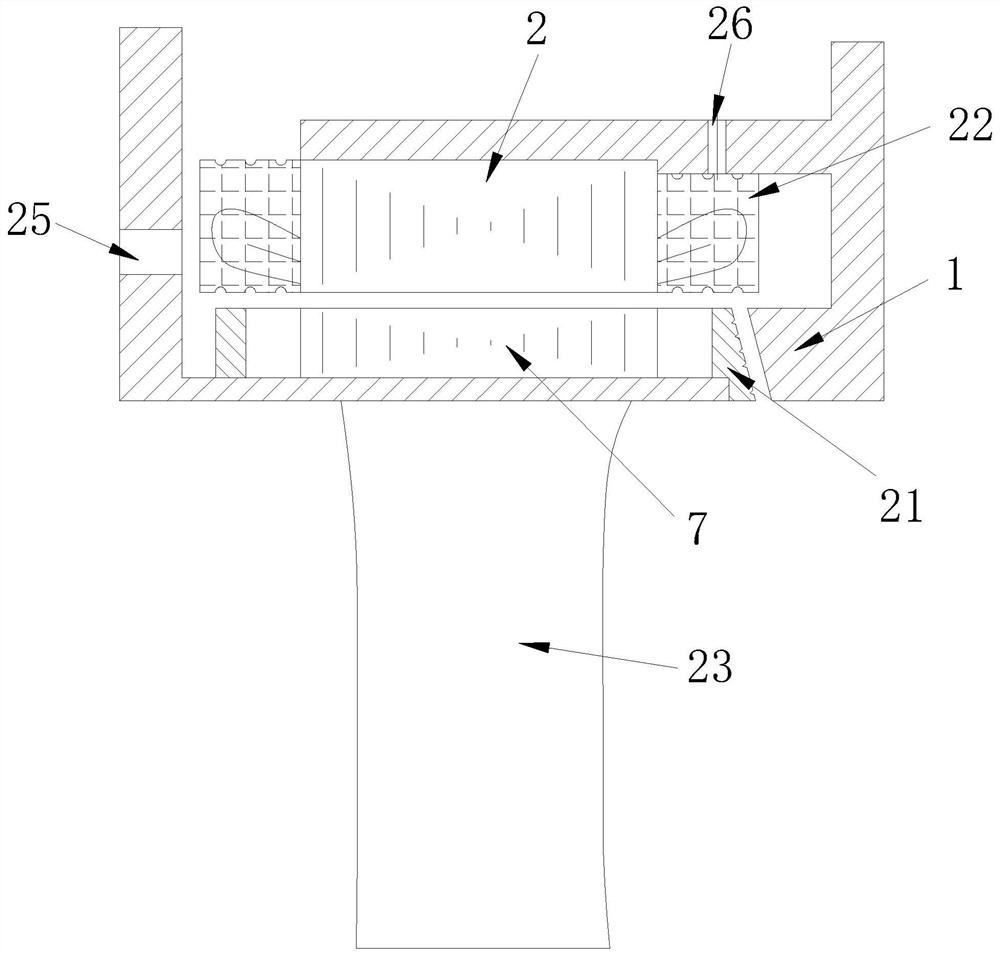

[0025] See Figure 1-3 Shown, a permanent magnet external rotor submersible pump, a water body 1, a stator 2, a rotor 7, the impeller 17, water 15, the impeller housing 18 and the shaft 9 that; rotor holder by a rotor 7 provided on the shaft sleeve 8 9, both ends of the rotary shaft 9 is provided with bearings 3 the water inlet, outlet end bearing 10; 3 inlet end bearing mounted in the center of the circumferential position of the water body 1, the bearing 10 is mounted in the outlet end 15 of the body of water circumferential center position ; both outlet ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com