A double-station alternate casting and welding production process

A production process and dual-station technology, which is applied in the field of dual-station alternate casting and welding production technology, can solve the problems of low production efficiency and poor coordination, and achieve small cooling range, improved service life, and good stability and uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

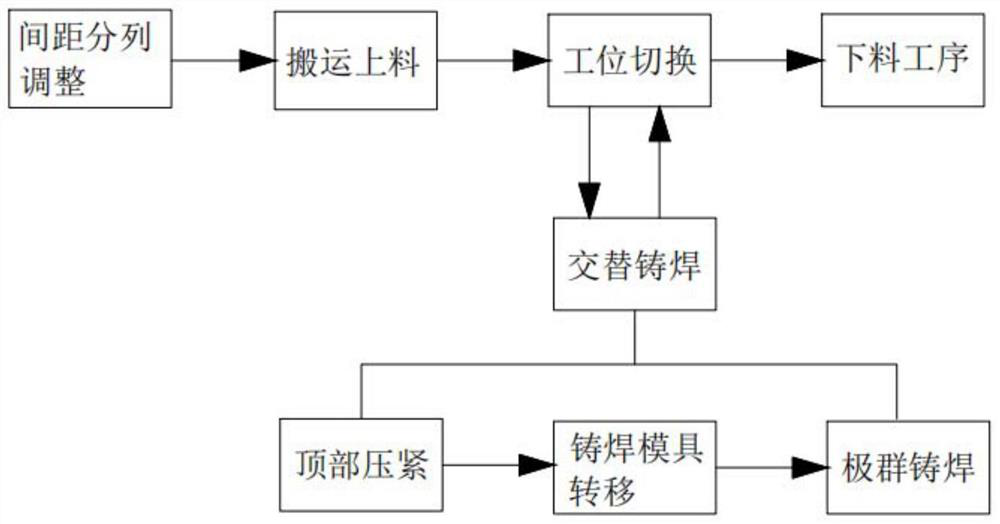

[0072] like figure 1 As shown in the figure, a double-station alternate casting and welding production process is characterized in that, it comprises the following steps:

[0073] S1, alternate casting and welding, the casting welding system 401 provided at the casting welding area 202 includes the casting welding unit 10, a plurality of groups of lead immersion units 20 and the casting welding molds 30 arranged in a one-to-one correspondence with the lead immersion units 20. The The casting and welding unit 10 carries the battery pack 101 , and the casting and welding mold 30 obtains molten lead liquid from the lead immersion unit 20 to perform casting and welding work with the casting and welding unit 10 and the battery pack 101 , and the plurality of casting and welding molds 30 alternately rotate. The casting welding unit transports the lead liquid required for casting welding.

[0074] In the present embodiment, when a group of casting and welding dies 30 are performing ...

Embodiment 2

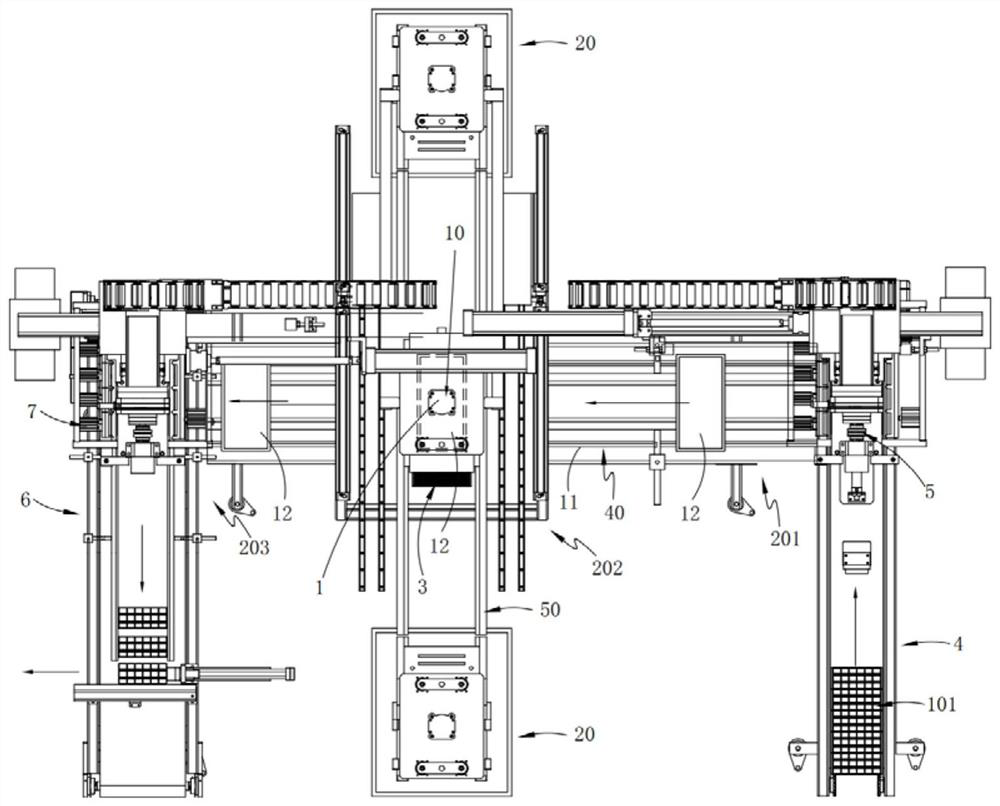

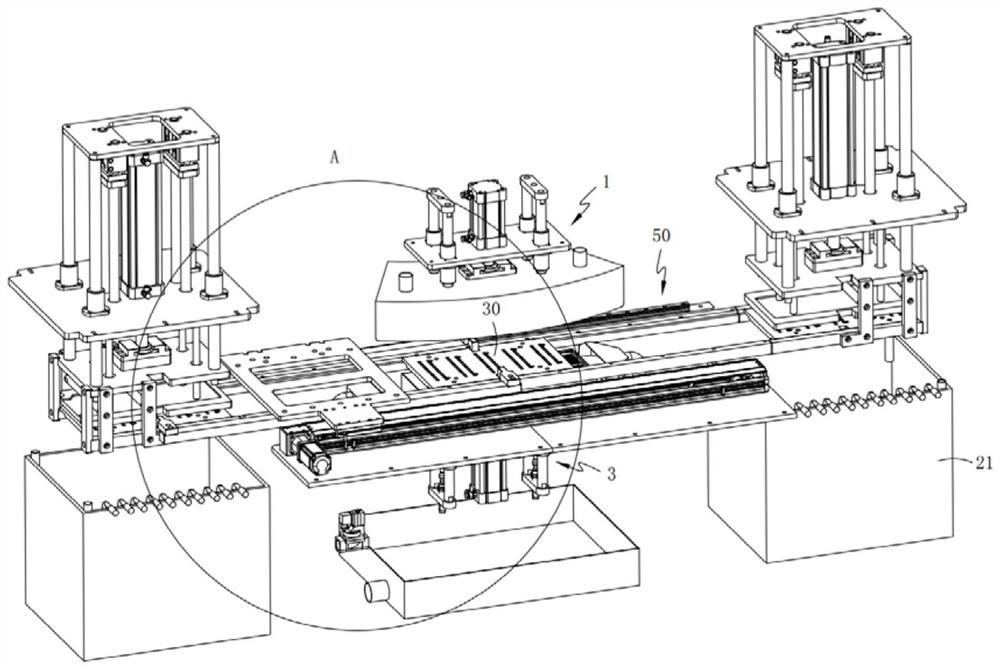

[0093] like Figure 2-3 As shown, a multi-station alternate casting and welding production line is provided with a casting and welding area 202 on the casting and welding production line, and a casting and welding system 401 is arranged on the casting and welding area 202;

[0094] The casting and welding system 401 includes a casting and welding unit 10 , a plurality of groups of lead immersion units 20 , a casting and welding mold 30 provided in a one-to-one correspondence with the lead immersion units 20 , and a casting and welding unit 10 and each corresponding lead immersion mold 30 . The transfer unit 50 for transferring the casting and welding mold 30 between the units 20;

[0095] Also includes a linear transmission unit 40 that transmits the battery pack 101 to the casting and welding system 401;

[0096] The battery pack 101 is transmitted to the casting and welding unit 10 through the linear transmission unit 40 , wherein a set of casting and welding molds 30 are i...

Embodiment 3

[0123] For the sake of simplicity, only the difference between the third embodiment and the second embodiment is described below; the difference between the third embodiment and the second embodiment is:

[0124] Preferably, as Figure 7 As shown, the bottom surface of the cover plate assembly 25 is provided with a protruding rib 251 which can be embedded in the forming groove 301 of the casting and welding mold 30 correspondingly.

[0125] In this embodiment, protruding ribs 251 are provided on the bottom surface of the cover plate assembly 25 . When the cover plate assembly 25 is matched with the welding mold 30 , the protruding ribs 251 can be matched and embedded in the forming grooves 301 . It can be sealed separately inside, so as to improve the isolation effect of lead slag. It should be noted that the width of the protruding rib 251 is slightly smaller than the width of the forming groove 301 and the protruding rib 251 can be just matched and embedded into the forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com