Aoi retractable board machine and retractable board method with sticky dust, flipping and coding functions

A turning mechanism and dust sticking technology are applied in the directions of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of indistinguishable boards, slow retracting and unloading speed, and board surface pollution, etc. Achieve high work efficiency, convenient operation, and solve the effect of limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

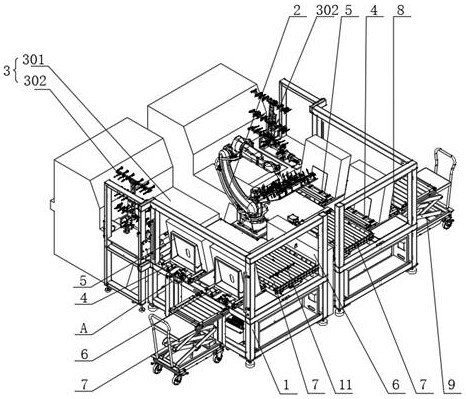

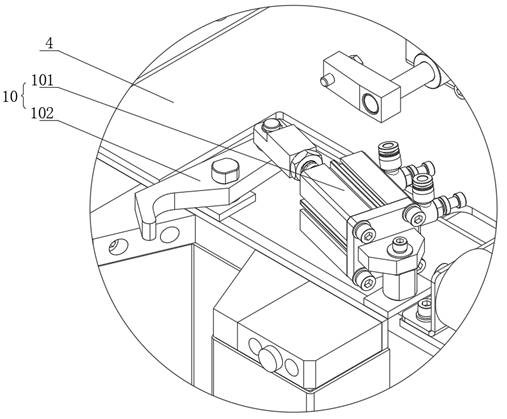

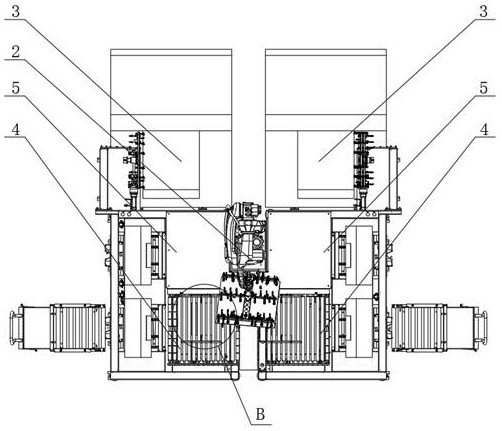

[0039] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0040] like Figure 1-Figure 9 As shown in the figure, the AOI retractor with functions of sticking dust, flipping, and coding in this embodiment includes a frame 1, and a manipulator 2 is arranged in the middle of the frame 1. Taking the manipulator 2 as the origin, the frame 1 is divided into Four quadrants, the first and fourth quadrants are detection position 3, the second and third quadrants are feeding position 4, and there is a discharge position between the detection position 3 of the first quadrant and the feeding position 4 of the second quadrant 5. There is a discharge position 5 between the detection position 3 of the fourth quadrant and the feeding position 4 of the third quadrant.

[0041] A sticky dust coding mechanism 6 is arranged between the two feeding positions 4, and the feeding position 4 includes an automatic transmission rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com