A method for removing prestressed anchor cable frame beams on roadbed slopes

A technology of prestressed anchor cables and frame beams, which is applied in roads, excavations, roads, etc., can solve the problems of unsuitable road subgrade widening and reconstruction construction, high safety risks of frame beams, and complicated technological processes, so as to avoid digging and breaking steel strands line, improve excavation efficiency, simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

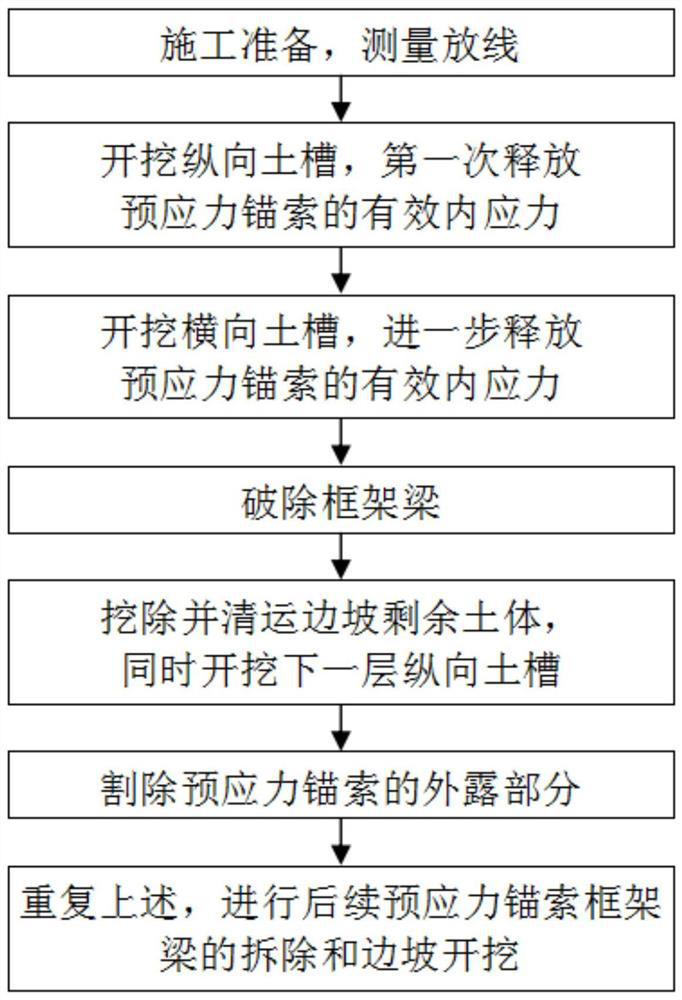

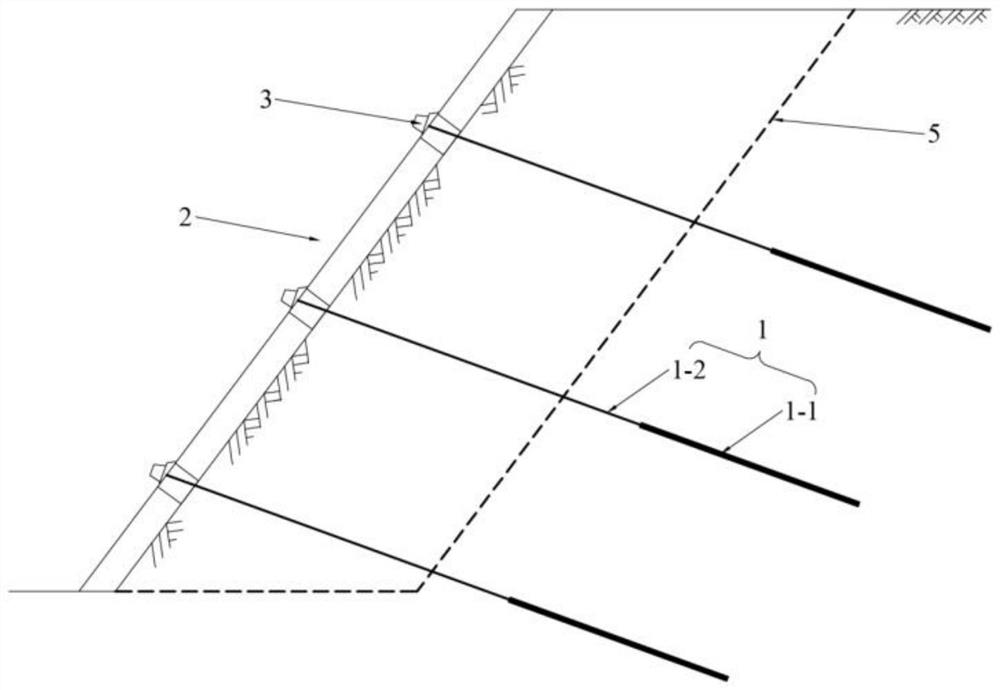

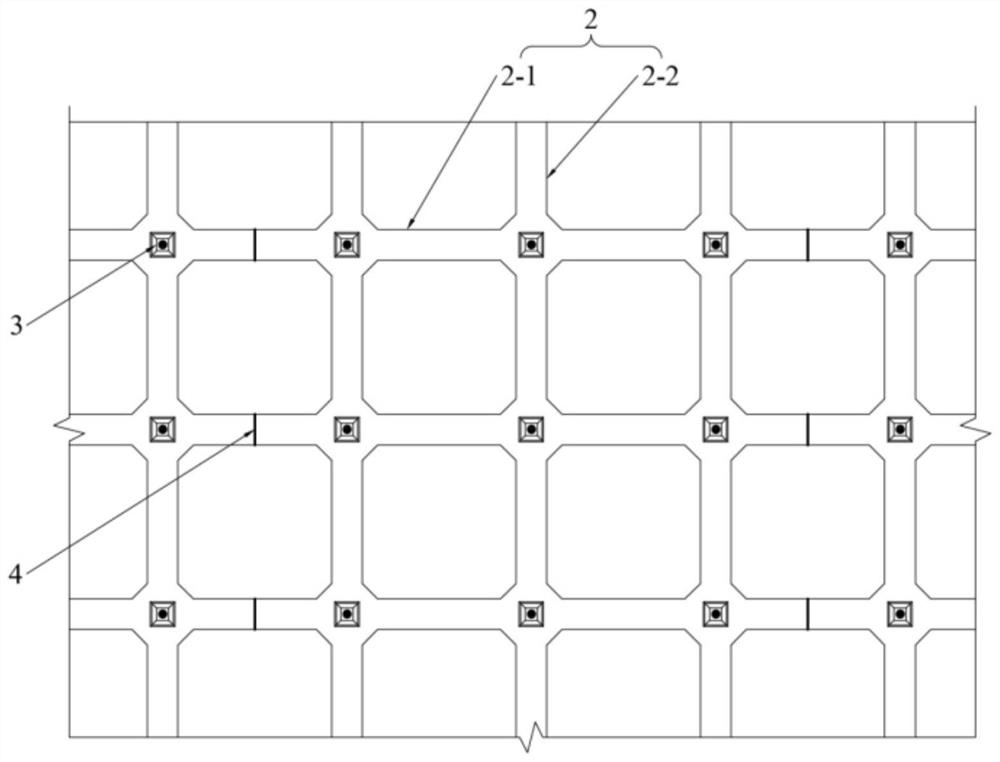

[0038] The invention provides a method for removing prestressed anchor cable frame beams on roadbed slopes, such as Figure 1 to Figure 6 As shown, it includes the combination of dismantling the supporting structure of the existing subgrade slope and the excavation of the widened subgrade slope, by excavating the vertical soil groove 6 and the horizontal soil groove 7 layer by layer at the top of the existing roadbed slope, Divide the soil mass of the side slope to be excavated for widening of the subgrade into multiple independent areas along the longitudinal and transverse directions, and use the elastic deformation of the soil mass to release the effective internal stress of the prestressed anchor cable 1, thereby ensuring the removal of the prestressed anchor cable frame beam Operational security, specifically including the following steps:

[0039] S1. Construction preparation, the surveyors release the inner boundary line at the top of the slope according to the widened ...

Embodiment 2

[0064] Such as Figure 1 to Figure 6 As shown, in this example:

[0065] Step S1, construction preparation, specifically, the surveyors release the inner boundary line at the top of the slope according to the widened subgrade slope line 5, build a construction access road, and use an excavator to brush the inner boundary line; from the inner boundary line of the slope top to the outside Level the site on the top of the existing embankment slope to form a work area, and mark the longitudinal mileage position of the prestressed anchor cable 1 in the leveled work area, where the longitudinal mileage position specifically refers to the direction of the first layer of prestressed anchor cable 1 along the road In order to prevent the anchor clips of the prestressed anchor cable 1 from being accidentally bounced off, a protective cover is covered above the head end 3 of the prestressed anchor cable 1, and the protective cover is made of a 20mm thick steel plate.

[0066] Step S2, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com