Anti-blocking high-temperature-resistant sewage pump and assembly process thereof

An assembly process and technology for sewage pumps, which are applied to pump devices, components of pumping devices for elastic fluids, pumps for special fluids, etc., can solve problems such as failure of sewage pumps, misfit of parts, and easy blockage of flow passages. , to reduce the risk of blockage, prevent overheating of the mechanism, and increase the degree of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

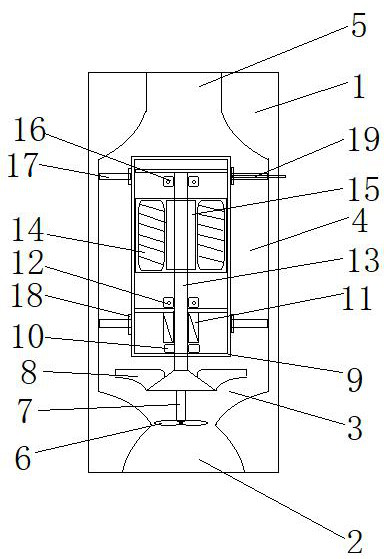

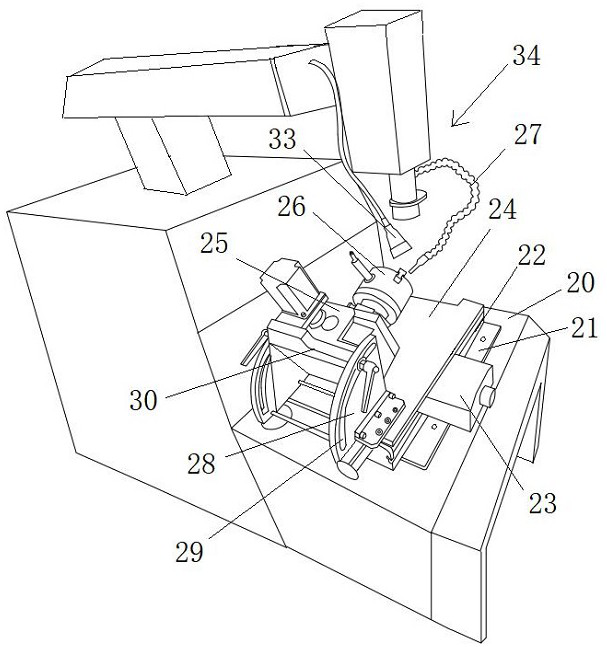

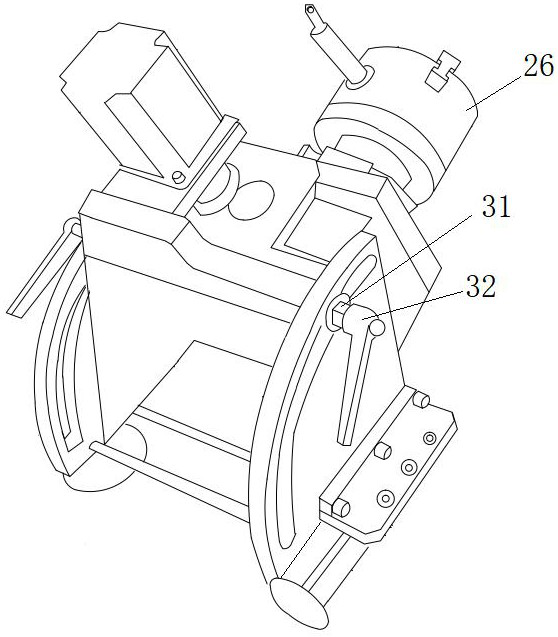

[0026] see Figure 1 to Figure 3 , the invention relates to an anti-blocking type high temperature resistant sewage pump and its assembly process, the assembly process steps are:

[0027] Step 1: Weld one end of the bracket 17 to the fixing block 18 and fix it by laser welding tooling 34;

[0028] Step 2: Fix the fixing block 18 on the side of the motor housing 9 with screws;

[0029] Step 3: Fix the connecting shaft 7 and the impeller 8 together by microwave welding;

[0030] Step 4: screw the screw through the hole in the center of the impeller 8 into the threaded hole at the bottom of the main shaft 13;

[0031] Step 5: Screw through the hole in the center of the blade 6 and screw it into the threaded hole at the bottom of the connecting shaft 7 to fix it;

[0032] Step 6: Weld the other end of the bracket 17 on the inner wall of the pump casing 1 by laser welding tooling 34;

[0033] The above assembly process is based on an anti-blocking high temperature resistant sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com