Drainage mechanism, heat exchange unit and heat exchange equipment

A heat exchange unit and heat exchange tube technology, applied in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of increased cost and structural volume, complex oil return control, poor system reliability, etc., to achieve Improved heat exchange efficiency, convenient oil return, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

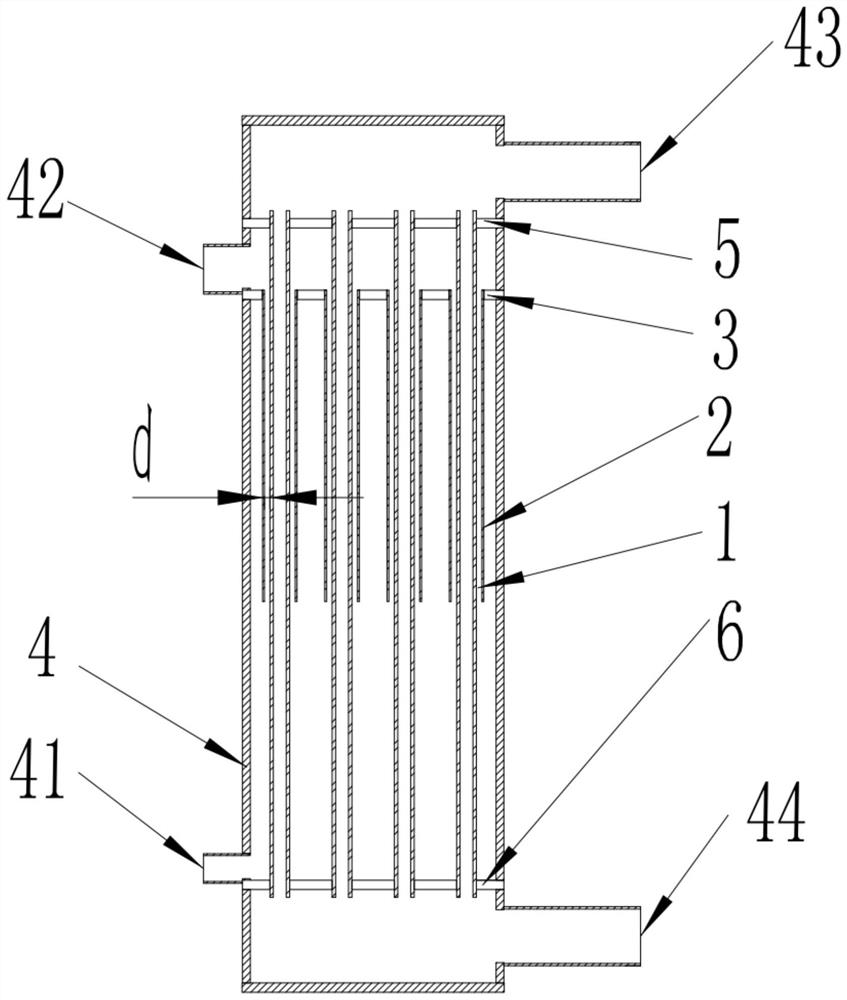

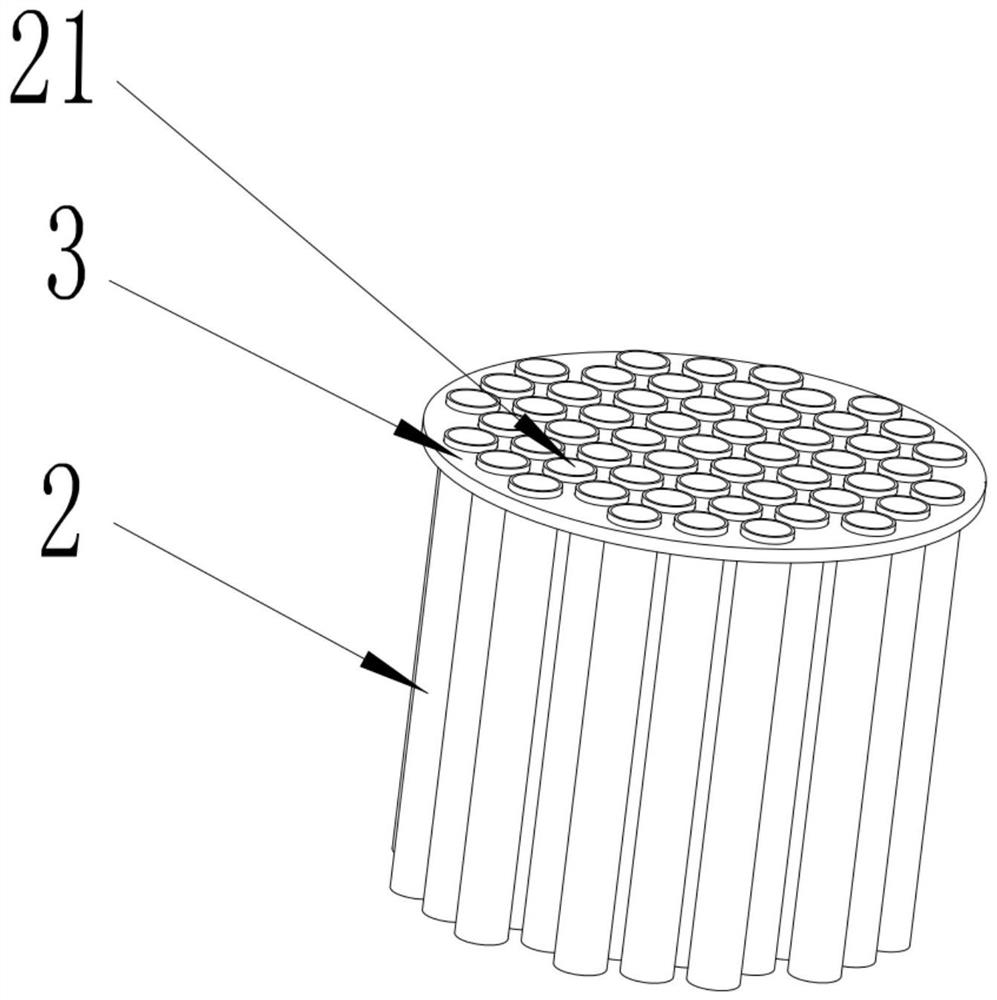

[0049]This embodiment provides a drainage mechanism for mounting with a heat transfer tube 1, such asFigure 1 to 3As shown, including: the drainage 2, the drainage 2 extends in the longitudinal direction of the heat transfer pipe 1; the drainage portion 2 has a drainage surface 21 disposed toward the outer wall surface of the heat transfer tube 1, and the drainage surface 21 is adapted to heat the heat pipe 1. The outer wall surface forms a climbing gap d.

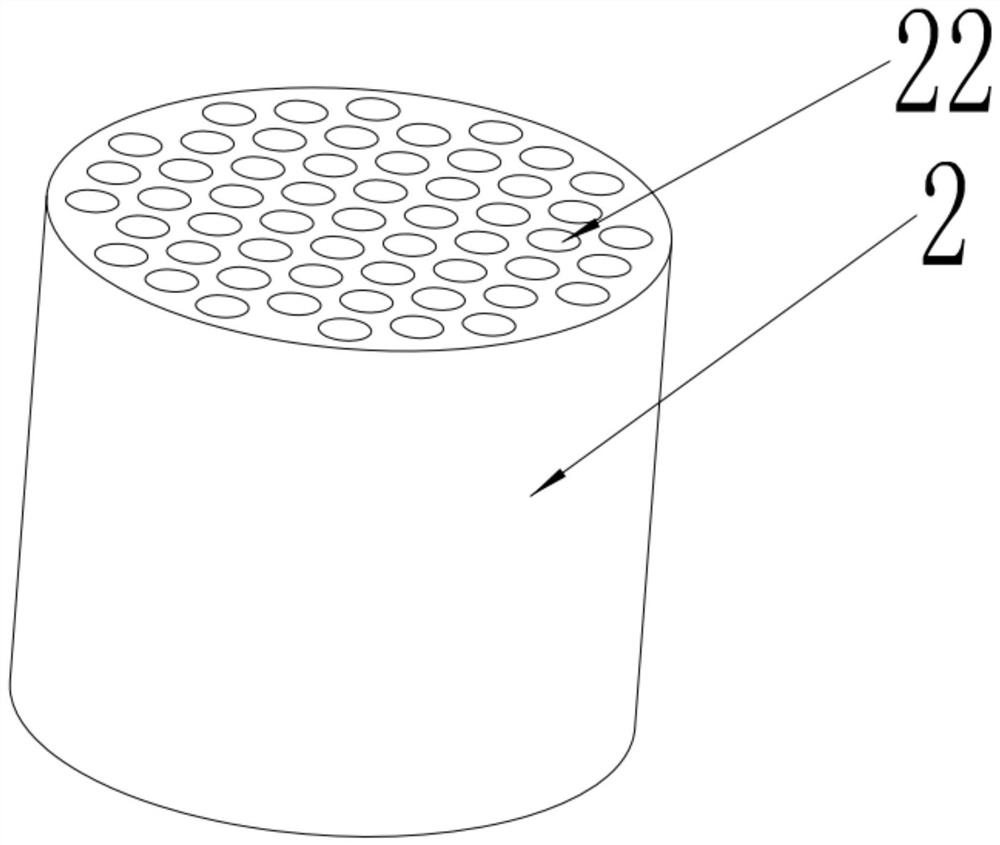

[0050]Specifically, in this embodiment, iffigure 2 As shown, the drainage 2 is a tubular structure. When the actual installation is used, the heat transfer tube 1 is disposed inside the tubular structure, so that the inner wall surface of the tubular structure is a drainage surface 21; for example, the tubular body can be a round tube. The circular tube is a closed surface along the cross section of the radial direction of the heat collecting pipe 1, and the present embodiment selects the closed surface as a circular tubular struct...

Embodiment 2

[0056]This embodiment provides a heat exchange unit including: housing 4, heat exchange mechanism, and drainage mechanism provided in Example 1. Wherein, the housing 4 has a refrigeration cavity, the refrigeration cavity suitable for flowing refrigeration cycle medium; the heat exchange mechanism has a heat transfer tube, the heat transfer pipe is mounted in the housing 4, the heat transfer tube 1 Suitable for the convergence of the cooling medium; the drainage mechanism is mounted within the housing 4, the diaphragm surface forms a climbing gap d of the refrigeration cycle medium climbing with the outer peripheral wall surface of the heat transfer tube 1.

[0057]The heat transfer tube 1 provided in this embodiment includes a tubular body and a first wing portion, wherein the first wing portion is disposed on the outer peripheral wall surface of the tubular body. That is, the heat transfer pipe 1 is an outer tube.

[0058]Of course, in other alternative embodiments, the heat transfer tub...

Embodiment 3

[0069]This embodiment provides a heat exchange device including the heat exchange unit, a press unit, and a pumping unit in Example 2. Wherein, the first refrigerant interface and the second refrigerant interface of the housing are respectively connected, and the pressure transfer unit is adapted to flow into or out of the refrigeration cycle medium; The two ends of the pumping unit are respectively coupled to the first cooling agent interface of the housing, respectively, the pumping unit being adapted to flow or flow into the cooling medium to the heat transfer tube. In this embodiment, the pressure transfer unit is a compressor and a refrigeration cycle loop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com