Switch tube

A switch tube and conductor technology, applied in the field of switch tubes, can solve the problems of poor reliability, high cost, and large bellows volume, and achieve the effects of good reliability and high mechanical life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

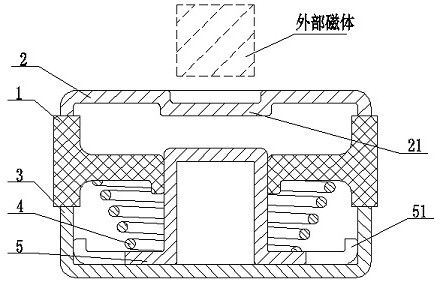

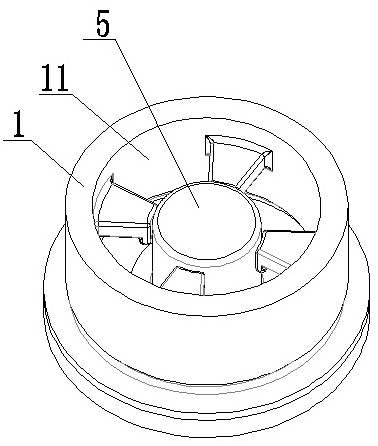

[0039] This embodiment discloses a switch tube, the switch tube includes an insulator 1, a first conductor 2 and a second conductor 3, and the first conductor 2 and the second conductor 3 are respectively arranged on the insulator 1 The two ends are welded and fixed to the insulator 1 respectively. The first conductor 2 and the second conductor 3 are respectively provided with cavities with opposite openings, the longitudinal section of the insulator 1 is H-shaped or I-shaped as a whole, and the insulator 1 is provided with a penetrating center hole, and the insulator 1, the first conductor 2 and the second conductor 3 are fixed to form a closed cavity. Preferably, the closed cavity is a vacuum structure, and the vacuum environment is favorable for breaking and arcing of the switch. off. Preferably, an arc-stopping gas such as nitrogen can be injected after vacuuming, and the nitrogen environment is favorable for breaking the switch and extinguishing the arc.

[0040] The in...

no. 2 example

[0045] Please refer to Figure 5 As shown, another form of switching tube is disclosed. The difference from the first embodiment is that the metal piece 5 includes a low-conductivity metal material and a high-conductivity material. The interior of the metal material with high conductivity, the metal material with low conductivity is set outside the metal material with high conductivity, or the metal material with low conductivity can also be set above or below the metal material with high conductivity, and the metal material with low conductivity is set below Taking the inside of the metal material with high conductivity as an example, the detailed description is as follows. The high conductivity material is copper or copper alloy, and the low conductivity metal material is permanent magnet or high magnetic permeability metal.

[0046] Please refer to Figure 5 As shown, the opening of the lower end of the metal part 5 is provided with a cover plate 53, and the cover plate 53...

no. 3 example

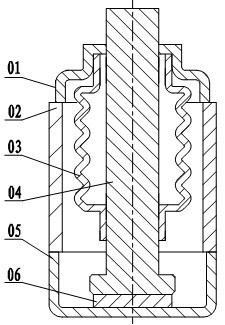

[0053] Please refer to Figure 7 As shown, this embodiment discloses another form of switch tube, which is the same as the second embodiment, the metal member 5 includes a low-conductivity metal material and a high-conductivity material, the difference lies in the structural form of the elastic member 4 Unlike the arrangement of the metal piece 5 in the second embodiment, the elastic piece 4 is in the form of a bellows, and the flexible conductor 6 and the metal piece between the metal piece 5 and the second conductor 3 are eliminated. 5 a boss 51 in contact with the second conductive member 3 .

[0054] Specifically, please refer to Figure 7 As shown, a permanent magnet 54 is provided in the inner cavity of the metal part 5, and the elastic part 4 adopts the structure of a bellows, one end of which is welded to the outer circle of the metal part 5, and the other end is connected to the second conductive part. body 3 is welded and fixed, and when the metal part 5 is in cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com