Positive electrode lithium supplement additive and preparation method thereof

An additive and lithium-replenishing technology, applied in the field of lithium-ion batteries, can solve the problems of inability to make full use of lithium ions, poor compatibility, and low pre-lithiation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

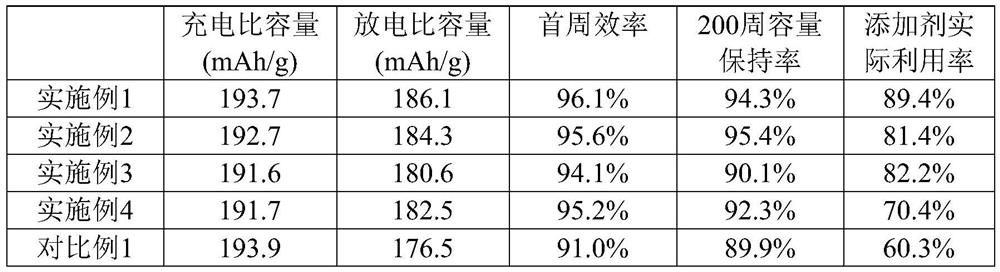

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing a positive electrode lithium supplement additive, the preparation method comprising:

[0035] Metal lithium is heated to 180°C under vacuum conditions to melt, with a pore diameter of 5nm, a pore volume of 0.4ml / g, and a specific surface area of 2230m 2 / g of carbon nanotubes are mixed, and the temperature is raised to 300°C at a rate of 2°C / min, so that molten lithium can penetrate into the pores of the porous carbon material;

[0036] After the molten lithium has infiltrated completely, at a rate of 1m 3 Nitrogen gas was fed into the mixture / min to react for 60 minutes. After the reaction, the mixture was cooled under an argon atmosphere to obtain the positive electrode lithium supplement additive, and the content of the porous carbon material in the positive electrode lithium supplement additive was 70 wt%.

Embodiment 2

[0038] This embodiment provides a method for preparing a positive electrode lithium supplement additive, the preparation method comprising:

[0039] Metal lithium is heated to 180°C to melt under vacuum conditions, with a pore diameter of 10 μm, a pore volume of 2.8ml / g, and a specific surface area of 103m 2 / g of carbon nanotubes are mixed, and the temperature is raised to 250° C. at a rate of 2° C. / min, so that molten lithium is infiltrated into the pores of the porous carbon material;

[0040] After the molten lithium has infiltrated completely, at a rate of 1m 3 Nitrogen gas was fed into the mixture / min to react for 10 minutes. After the reaction, the mixture was cooled under an argon atmosphere to obtain the positive electrode lithium supplement additive, and the content of the porous carbon material in the positive electrode lithium supplement additive was 20 wt%.

Embodiment 3

[0042] This embodiment provides a method for preparing a positive electrode lithium supplement additive, the preparation method comprising:

[0043] Metal lithium is heated to 180°C to melt under vacuum conditions, with a pore diameter of 10 μm, a pore volume of 2.8ml / g, and a specific surface area of 103m 2 / g of carbon nanotubes are mixed, and the temperature is raised to 300°C at a rate of 2°C / min, so that molten lithium can penetrate into the pores of the porous carbon material;

[0044] After the molten lithium has infiltrated completely, at a rate of 1m 3 Oxygen was introduced into the reaction mixture for 30 minutes per minute, and after the reaction was completed, it was cooled under an argon atmosphere to obtain the positive electrode lithium supplement additive, and the content of the porous carbon material in the positive electrode lithium supplement additive was 15 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com