Automatic label hanging machine and label hanging method

An automatic and labeling machine technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of high price, fish death, slow labeling speed, etc., and achieve the effect of efficient labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

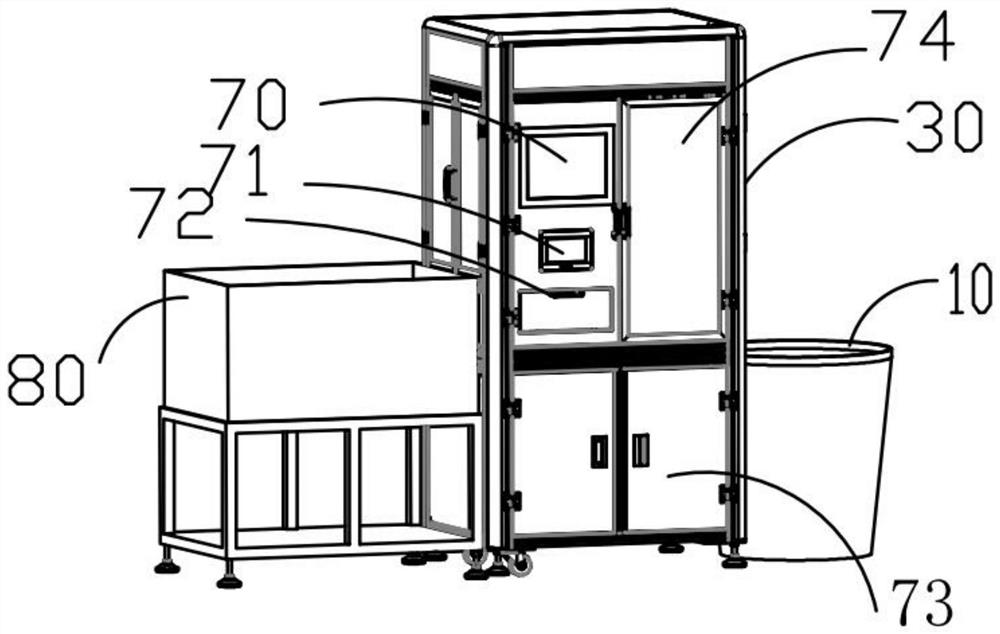

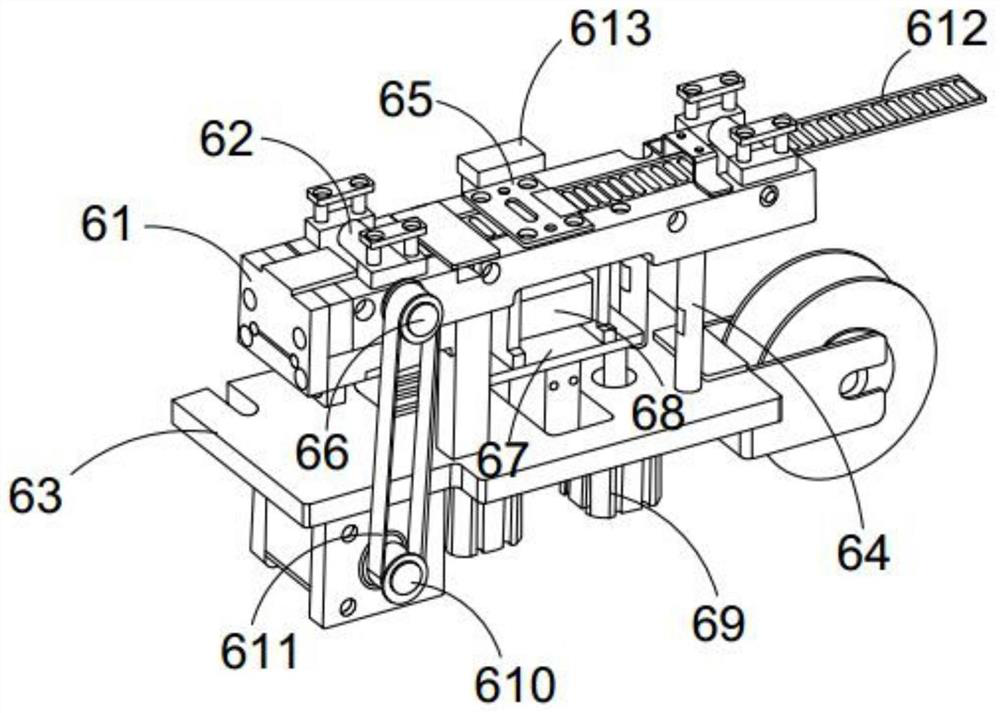

[0037] See attached Figure 1-9 As shown, the automatic tagging machine includes: a tagging box 70, the tagging box 70 is supported by the supporting frame body 30 and the supporting frame body 30 is provided inside, and the inside of the tagging box body 70 is also installed with a frame for moving the fish body along the horizontal The transmission assembly 20 for linear transmission, the two sides of the transmission assembly 20 are equipped with a limit mechanism 90 for limiting the position of the fish body through the support frame body 30;

[0038] The visual detection assembly 40 is located above the transmission assembly 20 and is fixedly connected with the support frame body 30 through the connecting frame body. The visual detection assembly 40 is located above the limit mechanism 90 and is adjacent to the limit mechanism 90. The limit mechanism 90 is close to the input end of the transmission component 20,

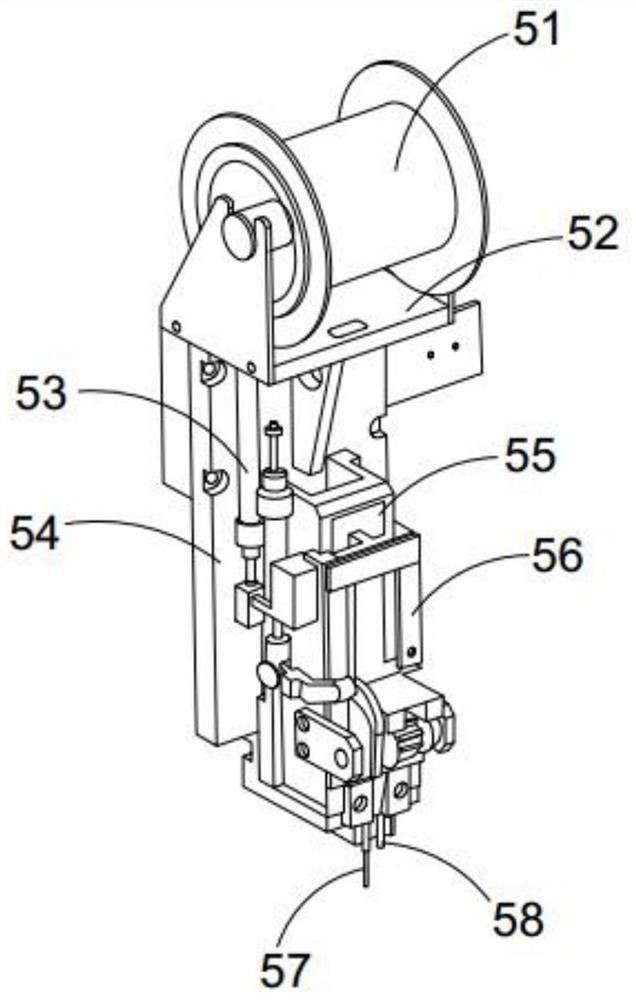

[0039] The manipulator 50 is arranged in the labeling box...

Embodiment 2

[0051] See attached Figure 10 As shown, an automatic labeling method using an automatic labeling machine, the steps are as follows:

[0052] -The visual detection component 40 collects images of the tagged fish and transmits them to the control unit, and the control unit locates and extracts the outline of the fish in the image, excludes the target area that is not the outline of the fish, and generates a coordinate system;

[0053] -The control unit sets the tagging area to occupy more than 1 / 2 of the back of the fish or the middle of the belly of the fish;

[0054] - The control unit determines the tangent line tangent to the back or abdomen of the fish according to the acquired image, and determines the perpendicular line of the tangent line as the marking point, and the marking point is located on the fish body;

[0055] - Control the fixed-point tagging operation of the manipulator according to the position of the coordinate system of the tagging point;

[0056] In the...

Embodiment 3

[0059] This embodiment further discloses the auxiliary calculation formula adopted by the control unit in the embodiment 2 for locating and extracting the fish contour in the image, specifically the following calculation formula:

[0060]

[0061] In the formula, K is the correction parameter (0.1<K is less than 0.2); xi is the coordinate point of the horizontal axis; yi is the coordinate point of the vertical axis; n is the area of the recognition image; i is the area of the fish outline.

[0062] In the present invention, by setting the tagging limit point under the conveyor belt of the fish body tagging area and setting a light-emitting device, this area is set as the image search target area, and the black area in the area is searched, and the fish body is illuminated by the light-emitting device. The image obtained at the position of the fish body is a black area, and the outline shape of the fish body can be quickly identified. The binarization threshold in the ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com