Intelligent electric power inspection robot with function of advancing in narrow space

A technology of intelligent inspection and robot, applied in manipulators, manufacturing tools, etc., can solve problems such as cumbersome maintenance, difficult travel and operation, and complicated tunnel layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

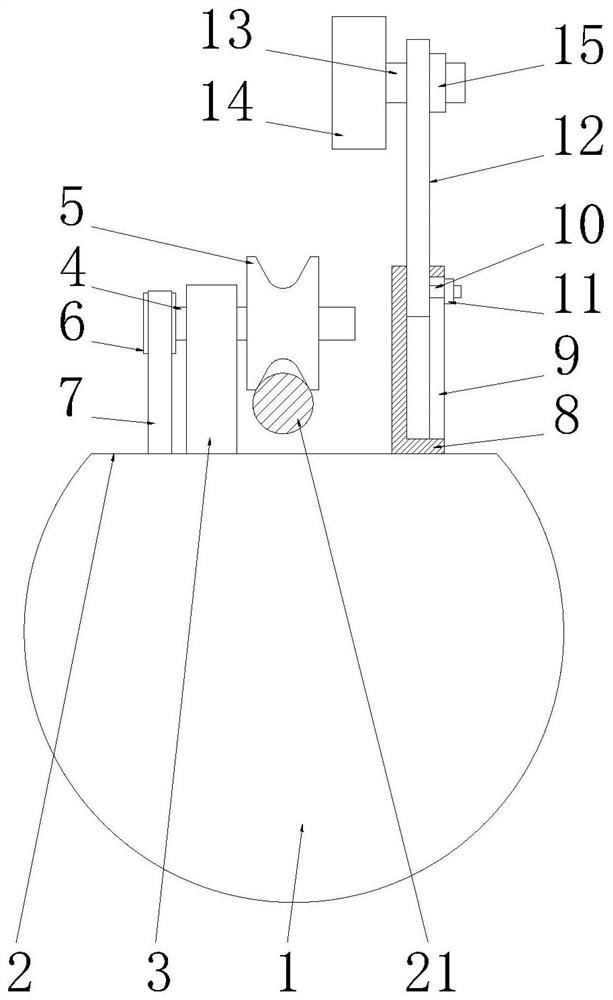

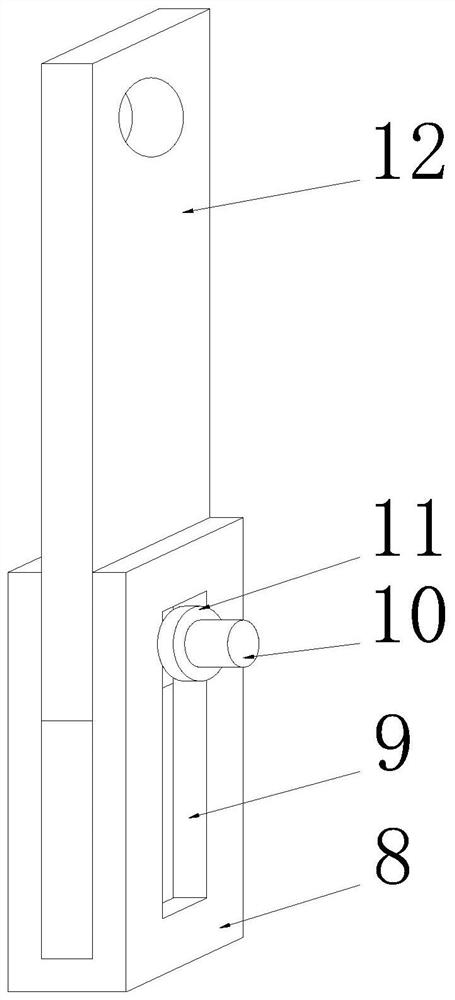

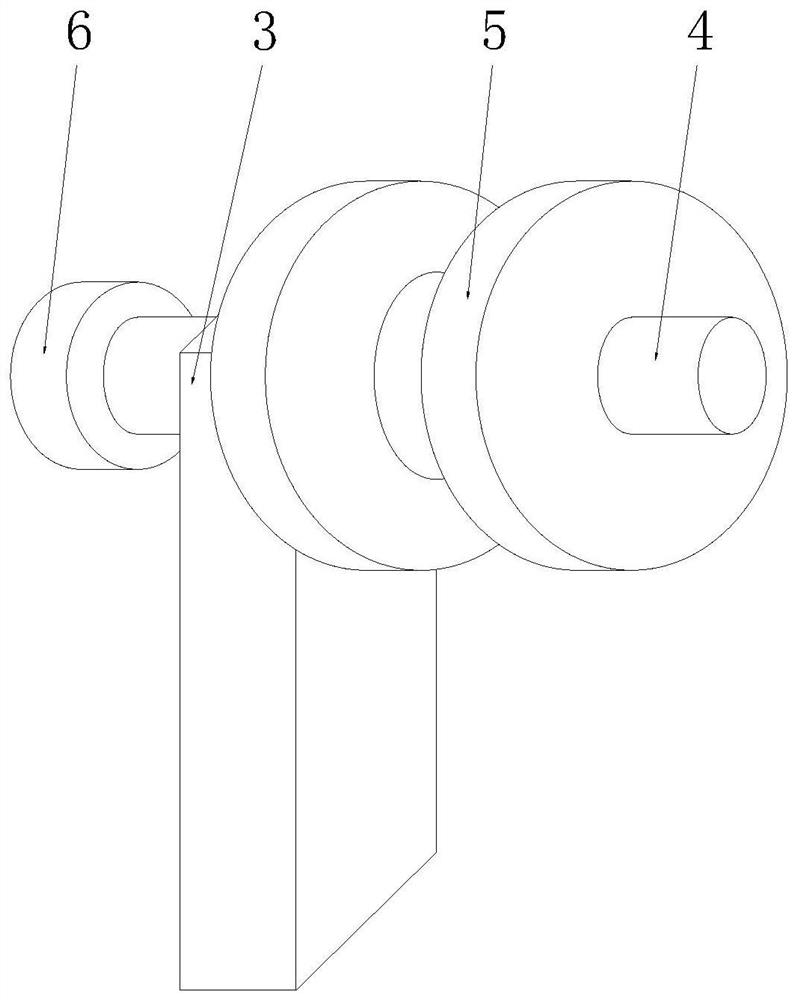

[0029] See Figure 1-5 , an electric power intelligent inspection robot with the function of traveling in a narrow space, including a work cylinder 1, the work cylinder 1 is a cylindrical structure, the top of the work cylinder 1 is provided with an installation platform 2, and the front and rear symmetry of the installation platform 2 A row wheel assembly is provided, and the row wheel assembly includes a foot plate 3, a bracket 8 and a drive motor 17, and the foot plate 3 and the bracket 8 are respectively fixedly connected to the top of the installation platform 2, and the foot plate 3 is arranged on the left side of the foot 8 The foot plate 3 is connected to the first rotating shaft 4 by rotation, and one end of the first rotating shaft 4 is provided with a walking wheel 5 matched with the track cable 21, and the other end of the first rotating shaft 4 is fixedly connected to the driven wheel 6. The support foot 8 is a U-shaped structure, and the side wall of the support ...

Embodiment 2

[0032] See Figure 5 , and the difference from Embodiment 1 is: the top of the working cylinder 1 is fixedly connected with a wireless transmission part 102, the wireless transmission part 102 is arranged between two row wheel assemblies, the wireless transmission part 102 is arranged obliquely, wireless The transmission part 102 is wirelessly connected to a mobile phone, a tablet computer or a notebook computer. By installing the wireless transmission part 102 on the top of the work cylinder 1, it is convenient for long-distance transmission of information. If it is too long, it expands the height of the entire device, thereby effectively limiting the volume of the entire device;

[0033] The top wall of the inner cavity of the working cylinder 1 is fixedly connected with the control assembly assembly 101, the bottom side of the working cylinder 1 is connected to the observation window 103, and the bottom wall of the working cylinder 1 is fixedly connected with a seat that ma...

Embodiment 3

[0035] See Figure 5-6 The difference from Embodiment 2 is that two track plates 108 are arranged on the bottom wall of the cavity of the working cylinder 1, and the two track plates 108 are symmetrically arranged on the front and rear sides of the observation window 103. The two track plates 108 are arranged in the inner cavity of the seat frame 104, and the track plates 108 are L-shaped structures, and a sealing plate 109 matching with the observation window 103 is slidably connected between the two track plates 108, and the sealing plate 109 is The right side end of the plate 109 is fixedly connected to the inner chamber wall of the working cylinder 1 through the second telescopic rod 110, and the outer side of the second telescopic rod 110 is provided with a pre-tension spring 111 matched with the sealing plate 109. The end of the preload spring 111 is fixedly connected to the inner cavity wall of the working cylinder 1, and the inner cavity bottom wall of the working cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com